No supplier relationship is perfect, and there will always be hiccups along the way. However, you may want to think twice if you repeatedly encounter one or more “red” flags. Look out for the following telltale signs of a bad supplier:

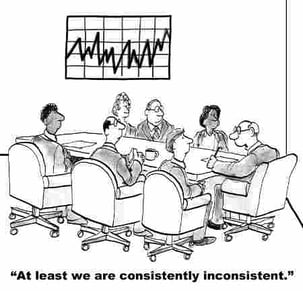

1. The story is always changing

First it was a delay due to an issue at a raw material supplier. Now it’s a government-mandated brownout to conserve electricity. The next thing you know, production grinds to a halt because one worker hurt himself using a saw. All of these examples are, in fact, real. But you’re not wrong in being skeptical if they occur repeatedly and affect your shipping schedule.

2. Your supplier is never wrong

You might hear that the increasingly poor quality you have noticed over the last 5 shipments is just your imagination and the result of your quality inspectors being too strict. You may be told to ignore the fact that you have documented an increase in returns from your top customers. You may hear the excuse that there must be an error with your data because the supplier’s quality remains stable. All of these are the supplier’s attempt to sidestep responsibility and put the blame on someone else. Hold your supplier accountable for quality fade and other issues. Avoid working with a factory that won’t take responsibility. Sidestepping responsibility is common sign that you may be working with a bad supplier.

3. Your supplier knowingly arranges inspection based on false information

A common example of false information occurs when you or a third-party schedule inspection for a certain date, only to arrive at the factory and find the product isn’t ready for inspection. The supplier booked the inspection knowing the factory would not be ready. This is generally done in an attempt to avoid the inspection process and is a HUGE red flag that indicates you need to inspect the order before shipping. If this happens repeatedly, then you run serious risk as an importer.

4. Your supplier provides vague criticisms of the inspector

It is common practice for suppliers to call inspectors incompetent or question their integrity. In most cases, you’ll find this coincides with an inspection report outlining a long list of quality issues. The only thing that might be more frustrating than a failed inspection report is to hear that the inspector didn’t know what he was doing or that he asked for money in exchange for going easy on the factory. If the factory is light on details, then your supplier is probably just trying to draw your attention away from the real issues. Insist that the factory make future complaints by phone while the inspector is still on-site. This is the only way to really investigate the issue.

Conclusion

If these examples remind you of a current supplier, then start to protect yourself by visiting the factory regularly in person. This allows you to see things for yourself and assess the situation. Your supplier will be less likely to lie to you in person if you make regular visits. And don't forget there are plenty of reputable suppliers out there with which you could be working. There are also companies that can help you identify them if you can't do this yourself. So be on the look-out for these signs of a bad supplier.