Best in Manufacturing – December 25, 2016

From all of us at InTouch, we’d like to wish you a Merry Christmas and a Happy New Year!

Each Sunday, we publish a list of top articles and other content related to manufacturing in areas like quality control, product development, supply chain management, sourcing, auditing and law.

1. A checklist for U.S. customs

You might have the best product imaginable. You’ve done market research and have spent countless hours in factories refining the item. Your marketing team has a killer campaign that no one doubts will send your profits soaring.

But there’s one obstacle that can turn all this effort on its head: U.S. Customs and Border Protection (CBP).

But there’s one obstacle that can turn all this effort on its head: U.S. Customs and Border Protection (CBP).

No matter where you import from, you need to prepare what’s legally required by the government. If your goods show up to port with half complete documentation or a total lack thereof, you won’t be allowed to sell in the U.S. And while you can sometimes provide missing information easily, there are other occasions when you need it from your supplier, which can seriously complicate your importing efforts.

The author mentions several items on the CBP Reasonable Care checklist that need to be addressed for goods to enter the U.S. market. Some of them are:

- Country of origin verification, marking and labeling;

- Valuation of merchandise consistent with specific CBP valuation rules;

- Free trade agreements;

- And more

Completing all the paperwork necessary for entry into the U.S. may seem tedious. But without it, your goods might end up floating on a boat at port instead of sitting on store shelves.

Learn how you can follow the law to make sure you avoid penalties, delays and CBP interference by checking out the full article in the link below:

A U.S. Customs Checklist to Minimize Your Import Risks – Fred Rocafort, China Law Blog

2. Manufacturing trends in 2017

With the passing of each year, technology continues to advance. And the changes new innovations bring aren’t confined to one specific industry. They’re not locked up in a box somewhere that only certain industries can access. Oftentimes, the innovations have a ripple effect across many segments of society.

In the case of manufacturing, 2017 will offer not only new changes and opportunities, but a unique set of challenges too. As Advanced Manufacturing’s reports highlight, how manufacturers in medicine, energy and other segments of manufacturing respond to the new year will determine their ultimate success or failure.

The author mentions that the scope of the reports covers a few areas, including:

- The increasing demand for precision;

- The need for greater speed in additive manufacturing;

- The need to improve in a profitable way;

- Forces at work in the economy;

- And more

2016 may seem like it just started yesterday. But a new year is already upon us, and by preparing for what it has to offer, you can make the most of it.

To learn about what changes manufacturers should expect to face in the 2017, check out the article in the link below:

2017 Manufacturing Trends – Editorial staff, Advanced Manufacturing

3. Remaining competitive in global manufacturing

It’s pretty safe to say that global manufacturing is a highly competitive field. While the U.S., China and Germany have firm holds on the top three spots, the contenders underneath them are busy pushing and shoving for a higher rank. The fight never ends.Employing smart factories in established manufacturing countries will help stay ahead of up-and-coming competition.

But how do you get ahead in this constant battle? The author mentions a few aspects that affect the competitiveness of up-and-coming countries and even those at the very top. They are:

- Keeping smart – Employing smart factories in established manufacturing countries will help stay ahead of up-and-coming competition.

- The need for a digital transformation – The companies that embrace Industry 4.0 can expect a 2.9 percent increase in revenue and a 3.6 percent cost reduction per year for the next five years. Countries that don’t encourage factories to keep pace with this change will be left in the dust.

- A potential skills gap – Great technology can’t do much unless there are people that know how to use it. The manufacturing workforce needs to adapt to innovations that constantly push the limits of productivity.

- Keeping ahead of the pack – Global competitors are investing heavily in technology; those that don't respond to this challenge will be left behind.

While you might excel in one of these areas, you might fall short in another. And that’s exactly where a foreign competitor might gain the upper hand. Only by addressing all of these aspects of manufacturing can you ensure that you remain prosperous, competitive and in a position ahead of the rest.

To learn about the other aspects that will affect the global manufacturing sector, check out the article in the link below:

Keeping Pace with the Changing Global Manufacturing Landscape – Stuart Hall, Manufacturing Global

4. Placing trust in the IoT

Reliable information is a cornerstone of any business. Without the ability to rely on coworkers, technology, reports and decisions, a company won’t last long. And that’s because when any or all of these aspects become distorted, they affect other areas, which can lead to poor choices and harmful results.

Enter the Internet of Things (IoT). The IoT could save businesses $630 billion by 2025 because of benefits like predictive maintainence. While that’s a huge amount of money, the figure might neglect the possibility that the IoT doesn’t always lead to the best outcomes. Fancy software isn’t a cure-all for bad management.

For example, the author mentions that the IoT can lead to “data deluge”. Just like an overwhelming amount of fake news can disrupt people’s perceptions of certain events, inaccurate or too much IoT data can mislead business leaders to make damaging decisions.

But why might that be? Human biases, bad sources of information and incorrect data collection algorithms are just several of the ways that the IoT’s data loses its typically helpful properties. Avoiding these pitfalls is key to ensuring that you can rely on the data you collect.

To learn more about the integrity of IoT data, check out the full article in the link below:

Can Internet of Things Data Be Trusted? – Tom Kaneshige, Internet of Things Institute

5. Graphene silly putty

When I was a kid, I loved playing with Silly Putty. In case you’re unfamiliar with the toy, it’s able to stretch, bend and snap. You can mold and dice the toy in any number of ways, and in the end, you can always bring it back together.

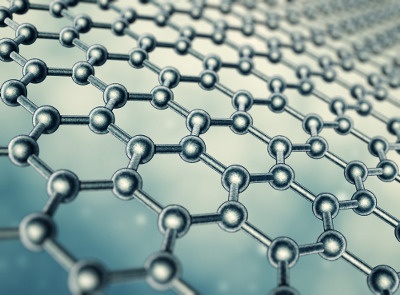

Now imagine that kind of versatility combined with the manufacturing applications offered by the super advanced manufacturing material graphene.

Now imagine that kind of versatility combined with the manufacturing applications offered by the super advanced manufacturing material graphene.

Researchers in Ireland at the Amber Research Center recently brought together the properties of Silly Putty and graphene. The result? An easily moldable substance with remarkable monitoring capabilities. The product is so sensitive to external stimuli that it was able to detect the footsteps of spiders walking across it.

This technology is still in development, but it could have a variety of applications in years to come, like in the wearable technology field. And who knows – maybe in the future factory workers could apply this graphene substance inside products, onto machines or put it in shipping containers to gather data that could be used for any number of improvements.

To learn more about graphene silly putty, check out the video in the link below:

Manufacturing Minute: Graphene Not-So-Silly Putty – Jon Minnick, Manufacturing.net

We’re constantly scanning the web for top manufacturing stories and news. If you’d like to submit an article for consideration for our weekly Best in Manufacturing, send us a message and let us know.