2020 has unearthed new challenges that many industries' owners were not prepared to solve. From 2020, we can learn important lessons to ensure that our businesses do not suffer from inadequate preparation in the future. The manufacturing industry was also a part of the industries affected by the 2020 events, and in the future, we are expecting radical changes in the manufacturing industry, such as the employment of useful tools such as AQF online in different businesses.

Increased Demand for Better Manufacturing Quality Control

Consumers are now more aware of what they want and when they need it. They have many products to choose from, necessitating companies to have better manufacturing quality control if they want to compete effectively and grow.

Consumers want affordable, high-quality goods that are delivered on time. To meet these needs, organizations need to centralize data, which allows them to carry out an effective analysis allowing them to figure out what the consumers need and deliver it to them.

Companies also need to focus on improving their supply chains. They can improve them by increasing their visibility, automating when necessary, and fixing any supply chains' weaknesses. By doing these, companies can improve customer loyalty and increase ROI.

Limited Data on the Supply Chains

Limited Data on the Supply Chains

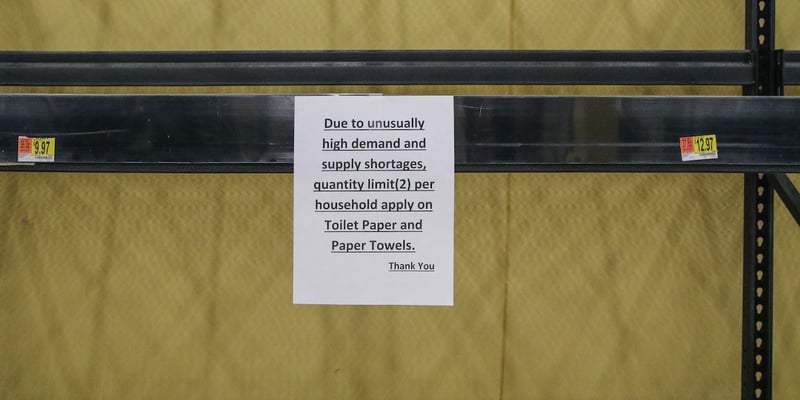

Covid-19 has affected supply chains negatively. The pandemic has taught organizations that their supply chains are vulnerable, and they need to identify these weaknesses. Mapping out the supply chains can help companies establish the errors and vulnerabilities in the supply chains that they need to solve.

Many companies are hesitant to map their supply chain because of the costs involved, but there are AI solutions to help minimize the process's costs. The pandemic has taught us that preparation for unprecedented occurrences can save businesses a lot of money. Therefore, when mapping out the supply chain, identify how natural disasters, strikes, and trade wars may affect the supply chain.

Digitization

To solve a variety of new challenges, companies start by collecting data. Once they collect the data, they can analyze it to improve manufacturing quality control, know what consumers need, and get any other information they require.

Once you collect data, you need to store it in an organized and user-friendly manner, and digitization is the solution. A tool like AQF online can help you with digitization in the business. The digitization done by AQF online aims at helping with manufacturing quality control by helping you avoid buying defective items, minimizing your risk, and selling your products quickly.

Overcoming The Challenges of 2020 with Asia Quality Focus

2020 has been a year full of unexpected and unprecedented challenges for many industries and manufacturing quality control is no different. AQF is a leading quality control service provider and our aim is to be a trusted partner, providing a valuable quality control experience through proficient, customer-centric teams.

To access our guidance and useful tools, sign up for AQF Online today. For any queries, contact us, and we will get back to you as soon as possible.