If you run any sort of manufacturing center, then you know how important productivity is. It’s not just about attaining a good level of productivity, it’s about consistently maintaining that level.

If you notice a drop in productivity, then you should immediately be investigating why that has happened. If you’re unsure what factors may be negatively affecting your productivity levels, then this article is here to help.

What do we mean by productivity?

Productivity is the rate at which your organization can produce goods/services in ratio to how you use resources.

There are a number of primary reasons why you may see productivity decrease. These include:

- Poor management (practices and communication).

- Outdated machinery.

- Failure to update software, processes, and other tools.

- Staffing problems

- Supply chain issues or scarcity of resources.

In this article, we will be focusing on factors that you can control or have a positive effect on in order to improve productivity levels.

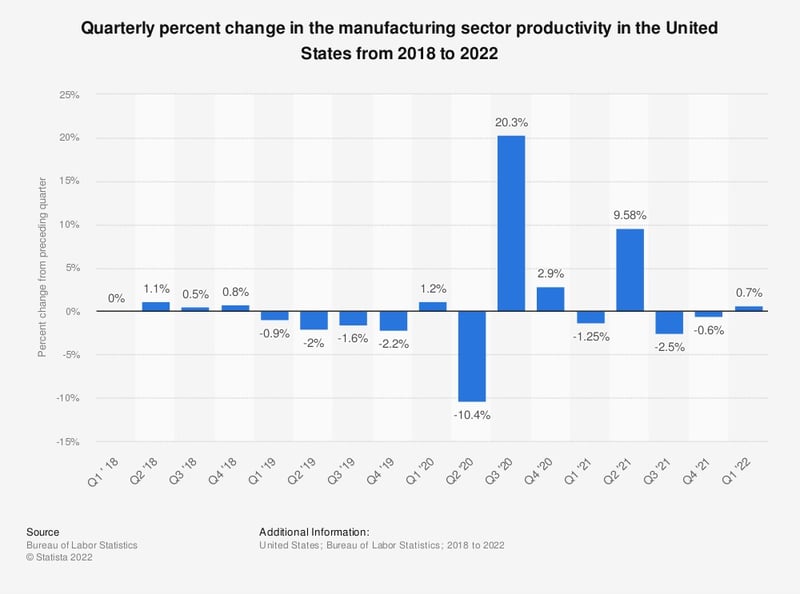

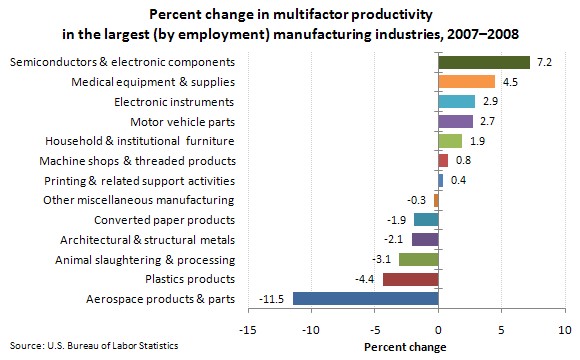

How to see and understand your productivity level

In order to improve productivity levels you need to understand your manufacturing process and how it’s linked to productivity. That means you need to look at how that process works and what affects it.

One method of measuring productivity is multi-factor productivity analysis (MFP), also known as total factor productivity. This method is both accurate and fairly easy to understand once you read up on it.

Outsource when you can

It would be nice if every business could carry out all operations in-house. However, this can increase costs and potential issues so you should be looking at the parts of your operations you can outsource.

Most modern businesses have some form of partnership involved in their manufacturing process. A good example is the car manufacturing industry. With up to 30,000 component parts in each vehicle, it makes good sense for businesses to outsource to third-party organizations.

AI and machine learning (ML)

AI-powered processes and machine learning are now used in almost every industry. From AI for call centers to AI-powered robots in car manufacturing, these systems help businesses improve productivity and reduce costs.

There are a number of reasons that AI and ML can contribute to better productivity; they can help identify maintenance needs before machinery breaks down, thus reducing potential downtime. Also, advanced diagnostics can reduce the time needed to fix any faults.

Combining AI and ML in your manufacturing process can also help with other factors, such as including quality assurance, allowing for customization of products when needed, optimizing workflows, identifying areas to reduce CO2 emissions with an environmental audit, and improving worker performance and capabilities.

Motivating your staff

Don’t forget to focus some of your efforts on ensuring that your staff are trained as well as motivated. Human errors can be costly, both in terms of financial losses as well as causing issues within the manufacturing process.

Offer incentives to employees who undertake advanced training, including better rates of pay as well as promotions. Including data-driven decisions in training can use predictive analytics to identify areas where training may be needed as well as areas where training has been successful.

Employee retention can be a crucial factor when it comes to maintaining or improving productivity levels; onboarding and training new staff can be costly and time consuming. Key drivers to employee retention can include ensuring they enjoy their roles, job security, and a work-life balance.

Training and education is especially important where companies are updating technology or adopting new tech. Having new processes implemented when staff are untrained can lead to real problems. Just as cloud security mistakes can lead to a loss of sensitive data, so can a poorly trained worker operating new machinery lead to a drop in productivity levels.

Analyze and improve processes

New technology and new machinery can be scary from a financial perspective as well as an operational one. However, your manufacturing process does not rely on solely technical aspects so it can help to analyze those processes on a regular basis to see if there is room for improvement.

These can include everything from supply chain logistics to inventory management. You can examine each factor in detail and, for example, see whether LIFO or FIFO is more efficient when it comes to managing and tracking inventory.

It is important that you cover every aspect of your production process. Think of your analysis as a map; where does your manufacturing process actually start and where does it end? By approaching this analysis methodically, you can identify areas for improvement..

Lean, mean, manufacturing machine

You want your production process to be as lean as possible to ensure overall efficiency in your manufacturing process. By ‘shaping up’ your production, you can improve productivity in several ways:

- Improve production times and eliminate wasted time.

- Save unnecessary costs.

- Optimize use of resources.

- Better time management processes.

Your target should be that leanest production combined with optimized levels of production. This should focus on areas where you identify potential for better performance such as inventory.

Of course, many of your decisions are based on customer demand and demand forecasting. While not an exact science, demand forecasting is essential when it comes to your planning and can be a major influencing factor on your productivity.

Listen to your customers

Your customers know that problems arise but listening to how they want you to deal with them can be very important. Good communications is essential to these relationships and it can make good sense to invest in PBX for small business to maintain that communication.

Customer perspectives can affect how you operate and can have a direct influence on your productivity. Their ideas can be extremely varied and can cover everything from grasshopper alternatives to better logistics suggestions.

Think green, think sustainable

While many green strategies may involve a large degree of initial investment, you have to look at them from a longer term perspective. Moving away from fossil fuels can lead to sustainable manufacturing and significant cost savings.

From factory location to the fuels you use to how you transport your goods, making green decisions now can have major impacts on your environmental footprint as well as your long-term productivity.

Solar and wind energy (combined) constituted only 1.7% of electricity generation worldwide in 2010. By 2020, that had grown to 8.7% and continues to grow. Looking at areas of your premises where you can switch to sustainable power generation can have major cost saving effects over time.

The takeaway

When it comes to improving your productivity, there are multiple tactics you can implement. While the most obvious of these are tech-based, there are many other ways where you can both save costs and improve your overall efficiency and productivity.

It’s also fair to say that most manufacturing sectors are becoming more competitive, so ‘keeping up with the Joneses’ is not just a trend, it may be a matter of business survival. Technology continues to evolve and innovate so making the right choice is a crucial decision when it comes to your business’s health.

At the end of the day, you want to be both productive and efficient and to see high customer retention rates. It can help to recognize factors such as that when you want to predict customer lifetime value SaaS can be of enormous value. Embrace the tech and analytics that offer real benefits; they really can make a difference.