Utilizing a single supplier occurs for one of two basic reasons. The first situation where this arises, we usually call “sole source procurement”, meaning we have no other choice but to buy from a lone supplier. The second is referred to as, “single source procurement” which occurs if your company voluntarily decides to buy from only one supplier - for example, by choosing to purchase only Dell computers, Dell becomes your single source by choice. However unlike those sole-sourcing, you and your company have the choice to switch suppliers. There is not only a material price consideration, but also overall leverage for aspects like quality, service, and marketing strategies to be considered.

Some companies have trouble separating the obvious benefits from the potential risks of using a single supplier sourcing strategy. This tendency has become even stronger in the last few years, especially throughout China. The reason is quite obvious - quickly climbing production costs. The solution of foreign companies in search of lowering their material costs is to involve various suppliers in order to compete for a lower price.

Single source (or sole source) is considered to be risky from a traditional point of view, so buyers are usually advised to avoid it. According to the traditional view; quality, cost degradation and supply chain risk are the 3 main areas under which single source risks are classified.

- Quality Risk - A serious quality defect could cause a fatal strike to the market reputation of the buying company.

- Cost Degradation - Once the supplier takes your resource channel, they will then get a resource-monopoly position.

No matter if they are “sole sourced” by necessity or “single sourced” by your own decision, they will become more powerful in future price negotiations with you.

No matter if they are “sole sourced” by necessity or “single sourced” by your own decision, they will become more powerful in future price negotiations with you. - Supply Chain Risk - This is a direct threat to your supply chain. As an extreme example, just imagine if your only supplier’s factory caught fire. What kind of disruption would this be to your whole supply chain?

At first look, using single suppliers does appear to be a highly risky solution in theory. But as we look at it from another perspective, single source procurement actually is quite different from a sole source situation. As a pro-active selection, it is an active strategy. But the potential risks are often over emphasized by companies when trying to develop a supplier plan in practice.

Delving into the Evidence:

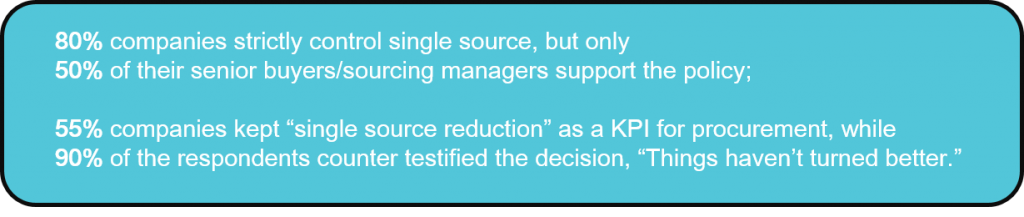

In May of this year, I was invited to deliver a speech about single supplier management in a sourcing summit in Beijing. A survey was conducted by asking 50 professionals, employed in China sourcing offices throughout various Fortune 500 companies, questions about their supply chain. The survey revealed the following interesting results:

The results from this survey display the difference in opinions surrounding the use of multiple suppliers versus a single source. This data clashes with the actual experience reported by many China-based procurement experts.

Challenging the Traditional View:

I. Challenge to Quality Risk:

The quality concern is part of frequent discussion surrounding products made in China. It has already garnered the attention of the whole nation, and huge measures have been taken in order to change public opinion.

When looking at this from a supplier’s perspective, we should ask ourselves honestly: Can prohibition of single-source procurement really solve this problem, and keeping the survey results in mind – would things really get better?

What is the real root cause? Let’s look at the typical scene of a joint venture in China:

Imagine a 200 or 300-staff factory, relatively small by China standards, located in one of the thousands of industrial development zones in China. These zones are usually located in relatively rural areas on the outskirts of big cities. Most young engineers are recent graduates that lack work experience in their field. This plant is responsible for the assembly of electronic control panels with orders taken from their U.S. headquarters, whose final products are then sent all over the world. Work lines are continuously busy and demanding with shipments always being pushed back, causing delays.

I have quite a bit of experience with these kinds of factories. On an optimal day, these kinds of factories can run 24 hours a day in order to meet the large order requirements asked by headquarters. However, quality issues are also a big headache for their Western headquarters operating thousands of miles away.

What would be a typical root cause of quality issues in these cases?

- A design problem:Keeping the following situation in mind, you can gain a better understanding of what can happen. A young, unskilled R&D engineer coupled with a great number of suppliers commonly leads to reduced levels of efficiency. Making mistakes in design and lacking adequate time to help the suppliers correctly understand the design requirements make a challenging task even tougher. Along with poor internal

alignments in quality and production engineering, sourcing cross functions make it extremely difficult for suppliers to follow. Now we know that the multi-source strategy is NOT necessarily the right solution to quality, while a reasonable, deliberated single supply strategy could be.

alignments in quality and production engineering, sourcing cross functions make it extremely difficult for suppliers to follow. Now we know that the multi-source strategy is NOT necessarily the right solution to quality, while a reasonable, deliberated single supply strategy could be. - Poor communication: Another major cause for quality issues in production can be directly correlated to poor communication. Cultural differences are usually seen as the main hurdle of success between a Western buyer and their Chinese supplier.

- Lack of systematic trainings to help your supplier improve: In some situations like on electronic lines, you will likely encounter highly-mixed BOM, lots of small demands, and frequently updated versions. As in the U.S. client’s story, the best way for you to manage improvements is to set up training programs for your supplier. Often times, we push suppliers harder on lower prices for compensation. However, the best way of helping ourselves is by actually helping our supplier.

- But as Western buyers communicating with new Chinese suppliers, it’s very easy to fall into thinking traps like, “Why can’t they produce strictly according to my drawings?” Check if you have omitted some specifications or documents, such as tolerance or other industrial standards – most likely your standards are new to them. Don’t be surprised if your new Chinese supplier has been in business less than 10 years. Especially in China, everything runs so fast, so you’ll find many of your vendors are comparatively young. To expect better performance from them, put yourself in their shoes and be careful to provide detailed specifications and requirements early.

II. Supply Chain Risk:

Single source procurement means that there is only one supplier available to provide you with the specified commodity or service. Any disruption your supplier has, can have devastating effects on your supply chain. But in general, the probability of that is low.

However, when a shock to supply really happens, multi-supplier sourcing may not be a good idea. A single source strategy could actually prove more effective under certain situations. Recall the Japanese Fukushima nuclear leak that happened back in 2011 and the shockwave that was felt in the surrounding areas? The Fukushima region plays a large role in providing a key raw material to the global electronic industries.  The leak’s effects actually spread to all related businesses and their downstream manufacturers, all the way to end users. Traces of the effects could even be found on the other side of the Pacific. So under the globalized structure of market and labor division, no one is really immune to a worldwide supply shock.

The leak’s effects actually spread to all related businesses and their downstream manufacturers, all the way to end users. Traces of the effects could even be found on the other side of the Pacific. So under the globalized structure of market and labor division, no one is really immune to a worldwide supply shock.

Coming from such a devastating situation, a Western company managed to leave quite a lasting impression. They quickly recovered in just the first week following the disaster. Their reason was relatively simple - they were the only ones who signed an exclusive supply contract with a distributor in their region.

III. Cost Degradation:

If you think that the multi-source tactic can help you in price negotiation, it might not be as easy in practice unless you have a large enough demand behind you. China is home to the largest number of suppliers in the world, with a majority able to produce and store huge amounts of product. Therefore, if you think you can obtain lower prices by increasing your supplier numbers, you might need to go up in scale. You would have to provide a significant enough amount of volume to catch numerous suppliers’ attention. Otherwise, your attraction to each supplier is diluted. You also need to be prepared for lower unit margins because of the market competition, as many industries maintain a very low profit rate. If you decide to work with several suppliers on the same molds and same production, for example, then you will have to double or triple your fixed assets investment. That will be an additional burden placed on your return.

In addition to the contract price, there are many more costs coming from quality, transportation and some other hidden aspects, such as shifting lines between different types. Unit price is NOT everything.

Multi-source procurement used to be popular in the automotive industry. But when comparing American and Japanese auto companies you will find that the Japanese used more single suppliers because they are more competitive. Why does that happen? The reason behind it is cultural - the Japanese place more emphasis on relationships when it comes to their business culture. Relationships with long term cooperation between companies can reduce the suppliers’ market efforts and risks. So the suppliers would often rather accept a lower price to keep this long term relationship going. This makes them more cost-effective than their competitors.

Speaking of these, a single source procurement strategy has great potential in the new era of business. In order to maximize your returns for doing business in China, the best strategy is not the old, straightforward competing mindset. The new mindset is to find a good supplier and keep a consistent, conflict-free, mutually beneficial, and long term cooperation between the two companies.

Speaking of these, a single source procurement strategy has great potential in the new era of business. In order to maximize your returns for doing business in China, the best strategy is not the old, straightforward competing mindset. The new mindset is to find a good supplier and keep a consistent, conflict-free, mutually beneficial, and long term cooperation between the two companies.

3 Tips for Using a Single Source Procurement Strategy in China

I. Embrace the Advantages a Single Supplier Offers

The traditional views emphasized the risks and negatives of using only one supplier for purchasing. Traditional-minded buyers are risk-averse and worry about the potential damage caused by a disruption in supply when using a single source procurement strategy. Instead of splitting focus between multiple suppliers, choosing a dependable supplier and dealing with problems as they arise can be a better solution than the traditional manner in many cases.

This is actually a solution based on a relatively new perspective. In earlier times, the Chinese learned how to deal with floods by digging canals instead of building dams. This is a good metaphor to illustrate the point about utilizing a single source strategy. There are those who tend to refuse taking on the risks of using a single supplier. However, if you grasp the advantages of focusing on a single supplier, you will be able to channel those advantages productively and exploit the additional benefits.

II. Remember, Sometimes “More is Less!”

By way of example, a European client in China had just about 2,000 local suppliers for only 500 different items – meaning 4 vendors per product on average! Remarkably, there were only two buyers responsible for all of the daily purchasing! Too many suppliers can cause low work efficiency and hinder your team spirit!

III. A Systematic Supplier Development Plan

If you really care about your supplier’s quality and want to improve it, the best way is to set up a supplier development plan and train them with patience!

What is a Supplier Development (SD) Plan?

In normal practice, there are different theoretical approaches to “supplier development” (SD). The popular approaches include the theory of Transaction Cost Economics (TCE), Resource Dependence Theory (RDT) and others.

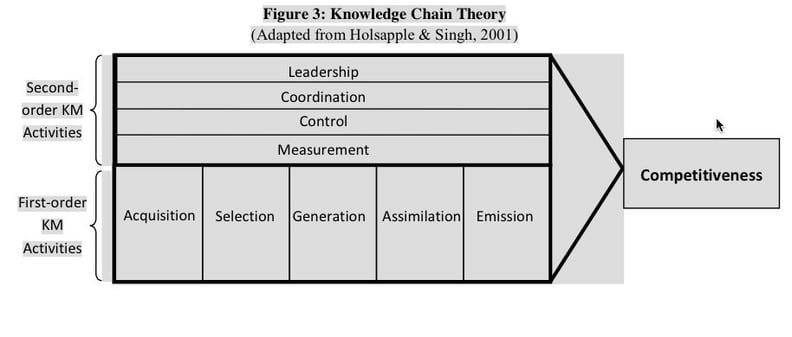

The most recently developed SD systematic theory is called Knowledge Chain Theory. The theory works by integrating nine different aspects of an effective supplier development plan into one systematic approach. The Knowledge Chain Theory is a wide-ranging approach, and would be a great fit for the complexity that often comes from doing business in China, having practical applications to most real-life situations.

Conclusion

In closing, when purchasers ask the question, “should I use a single source or multiple suppliers in China?” they may be asking the wrong question.

The answer to finding a sourcing solution should focus on developing a creative, reliable and long term supplier partnership. That is what really matters when it comes to a healthy and successful business solution while manufacturing in China.

Acknowledgements:

Special thanks to my friend, Mr. Chen Liang, for his contributions to Expectations Theory and Supplier Development in my research. Mr. Chen is a PhD Candidate now in University of Kentucky, and formerly a senior market analyst in China.

About Shuo Wang

Shuo Wang is a Chinese freelance writer and coach on SCM improvement. He founded Smart Decision consulting firm and is a member of the Society of Decision Professionals. He has 18 years of global experience in sourcing and supply chain management, having held senior positions in various industries, working in Shell Oil and Gas, Siemens Building Technology, and Vestas Wind Technology. With broad experience from billion-dollar projects management, to strategic sourcing activities, he focused on helping clients to improve performance end to end. He can be reached at: patrick.wang@globalsmartdecision.com.

Shuo Wang is a Chinese freelance writer and coach on SCM improvement. He founded Smart Decision consulting firm and is a member of the Society of Decision Professionals. He has 18 years of global experience in sourcing and supply chain management, having held senior positions in various industries, working in Shell Oil and Gas, Siemens Building Technology, and Vestas Wind Technology. With broad experience from billion-dollar projects management, to strategic sourcing activities, he focused on helping clients to improve performance end to end. He can be reached at: patrick.wang@globalsmartdecision.com.