Best in Manufacturing – October 29, 2017

Each Sunday, we publish a list of top articles and other content related to manufacturing in areas like quality control, product development, supply chain management, sourcing, auditing and law.

1. Chinese counterfeiters: chased and hunted by secret agents

If you were to sit down in a room and evaluate two nearly identical handbags in front of you, would you be able to spot which one is a fake and which one is not? Or if they’re both fakes? Or both genuine?

I think in general, I’m able to spot a fake from a genuine product. But where I and many others lose that ability is when presented with a good fake.

This is where the counterfeit detectives mentioned in this featured article step in. They’re at the behest of major international brands trying to remove the constant thorn in their sides that is counterfeiting. And there’s plenty to go after – $400 billion is the size of the counterfeiting industry in China.

The detectives weed out fake parts, components and completed goods before they enter supply chains. They prevent knockoffs, of both high and low quality, from going on sale at local markets throughout China. Most importantly, these detectives look for the manufacturer(s) of the counterfeits so as to prevent their continued production.

However, there’s another side to the story. While in theory it sounds ideal to completely eliminate the entire counterfeiting industry, the initiative could strongly disrupt local economies, which could threaten social stability. Local governments need that stability and a tax base to pay for public services. So in a way, the counterfeiting industry is slightly necessary… at least for now.

Curious about what raids of counterfeit goods are like and why the counterfeit industry is almost a necessary evil in China? Follow the link below to find out more:

On a Raid with the Secret Agents Chasing China Counterfeiters Who Cost Big Corporations Billions – Joshua Hunt, SCMP

2. Why millions of Hindu statues are made in China and not India

It’s pretty fair to say that there are lots of Hindus in India. Eighty two percent of the Indian population practices Hinduism. Yet despite this large number of Hindus, many of the statues of deities found in Hinduism are made in China, rather than locally in India. In exploring this conundrum, it’s possible to see why China is currently more of a factory to the world than India. (For reference: Chinese exports to the world: $2,098 billion; Indian: $264 billion).

The author of this featured article lists several factors that account for the trade deficit balance between China and India, which also reveal why India still has some catching up to do to become a major manufacturing nation. Some of those factors are:

- Productivity: Workers in China may be paid around four times as much as workers in India. But they’re also more productive – much more. “…workers in India’s manufacturing sector are almost four and five times less productive, on average, than their counterparts in Thailand and China, respectively.”

- Corruption: In China, corruption occurs at higher levels. In India, it occurs at lower levels, which affects day-to-day operations more than in China.

- Electricity: Indian businesses suffer from chronic blackouts and power shortages. Chinese businesses, by contrast, benefit from an uninterrupted stream of electricity. Without dependable electricity, manufacturing efficiently and reliably becomes much harder.

- And more

India has its Make in India initiative and is trying to address some of these issues. Similarly, China has Made in China 2025. These two government programs aim to considerably develop their countries’ manufacturing sectors and put them on par with the likes of Germany, Japan and the United States. Yet while China advances more toward an advanced manufacturing economy, India is trying to cement the basic necessities of good manufacturing and infrastructure.

To learn more about the differences in manufacturing between China and India (and why Hindu deity statues are made in the former, rather than the latter), check out the full article in the link below:

Made in China: Millions of Hindu Gods – Farok J. Contractor, YaleGlobal Online

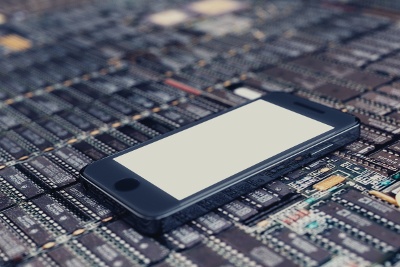

3. A new PCB manufacturing method for advanced electronics

Back when I was a kid, I had a flip phone. It was really cool, to be honest. I loved arrogantly flipping it open and taking photos like I was a professional photographer. Fast forward to today, and flip phones have been replaced in many locales by smart phones that are generally only slightly bigger and with remarkably greater processing power.

There’s a host of reasons why smartphones have advanced past flip phones. One reason is upgrades in device density via high-density interconnects (HDIs). The ability to pack more functionality, power, memory and so on into the same confined space has enabled smartphones to provide more value to end users.

And as the author of this featured article mentions, in order for 4G LTE smartphones to evolve, so too does the manufacturing process required to make them. The author points to using a semi-additive process (mSAP) to create the HDIs of smartphones.

This manufacturing technique maximizes “circuit density and accurate impedance control”. Phones of the future will need this new process to deliver the constantly improving features that consumers have come to expect.

Do you think this manufacturing process holds promise for other electronics? Let us know in the comments section below.

To learn the details about how mSAP works and how it can help smartphones, check out the full article in the link below:

mSAP: The New PCB Manufacturing Imperative for 5G Smartphones – Meny Gantz, Electronic Design

4. A host of quality tools to help your decision making

“Why are there dents on all the product packaging?” You ask yourself. And soon enough, you see the reason: a machine is incorrectly automatically packing your order. Sometimes, fixing quality problems is this straightforward. But improving (or assuring) quality isn’t always so simple.

For those times when you need to think about the quality problem(s) facing you in greater detail, you can turn to the old and new quality tools mentioned by the author of this featured article. I’ll mention a few below.

- “Classic” tools

- Cause and effect diagrams: this diagram displays the potential causes of a problem and looks almost like a tree. The main “branches” are usually “man, material, methods, milieu (environment), machine and measurement”.

- Histograms: this diagram displays the distribution of data. Using this type of data display, you can quickly determine if the data are skewed one way or another.

- Flow charts: use this tool to break down and better understand a process.

- New management/planning tools

- Affinity diagram: you can utilize this tool to understand cause-and-effect relationships between concepts.

- Arrow diagram: this tool helps understand steps toward finishing a process/project based on time.

- Prioritization matrix: by using this tool, it’s easier to find the optimal choice considering weighted values to certain characteristics.

To learn more about these tools and the others mentioned by the author, be sure to check out the full article by following the link below:

Combining Quality Tools for Effective Problem Solving – Matthew Barsalou, Quality Digest

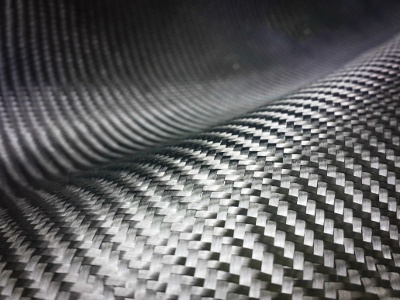

5. Carbon fiber’s important future role in design and manufacturing

Do you know what carbon fiber is?

In the past, I heard of it in science fiction television series, in important sounding research news articles and elsewhere. And while I could clearly grasp that it was a pretty remarkable material, I didn’t understand exactly what it was… until I decided to clear up the ambiguity.

From Innovative Composite Engineering:

From Innovative Composite Engineering:

Carbon Fiber is a polymer and is sometimes known as graphite fiber. It is a very strong material that is also very lightweight. Carbon fiber is five-times stronger than steel and twice as stiff. Though carbon fiber is stronger and stiffer than steel, it is lighter than steel; making it the ideal manufacturing material for many parts.

And it’s for these reasons (and a few more) that the author of this featured article thinks carbon fiber will become ubiquitous in products ranging from furniture to clothing and more in the years to come. I’ll mention a few reasons below.

- Cost: research breakthroughs are leading to reductions in price that could expand how widely the material is used. And some industry reports, like Carbon Composites Are Becoming Competitive and Cost Effective, indicate that the material is growing in popularity and usefulness.

- Versatility: from soccer shoes to car bodies to whole roofs – carbon fiber is a material that has many different use cases.

- Look: previously, carbon fiber material was plain black. Understandably, that limited usage due to aesthetic constraints. Now the material is available in color, expanding the ways in which designers and manufacturers can utilize carbon fiber.

Curious about carbon fiber? Check out the featured article in the link below to learn more about this amazing material:

Five Reasons Why Carbon Fibre Is the Future of Design – Editorial staff, the Manufacturer

We’re constantly scanning the web for top manufacturing stories and news. If you’d like to submit an article for consideration for our weekly Best in Manufacturing, send us a message and let us know.