Since there are literally thousands of manufacturers producing different cleaning supplies, it is highly important for consumers to pick the best cleaning supplies out there to ensure that every penny spent is worth it. In order for manufacturing industries to continuously provide quality products, there are certain inspection protocols to be performed to make sure that it adheres to international quality control standards.

Depending on the cleaning supply being manufactured, there are specialized inspection processes to be done to ensure that all of the products meet the highest quality possible. Since there are different types of cleaning supplies, here are the different products and the inspection processes to be done:

PRE-PRODUCTION INSPECTION

The purpose of this inspection process is to verify that all of the necessary equipment, machinery and materials to be used during production are free from any defects or damages to ensure that all of the necessary equipment is working as expected.

- For Non-Mechanical Cleaning Supplies – all of the materials, tools and mechanisms to be used must be inspected to ensure that all of the tools are free from any damages, defects or raw material anomalies. Once products are thoroughly inspected, products will undergo the next production queue.

- For Mechanical Cleaning Supplies – since mechanical cleaning products involve electricity, each component must be inspected for any loose parts to ensure that all of the necessary components are intact prior to the initial assembly queue.

- For cloths – all of the necessary materials needed for foam, cloth, or sponge production must be thoroughly inspected to ensure that all of the threads and other materials are ready for the next production queue.

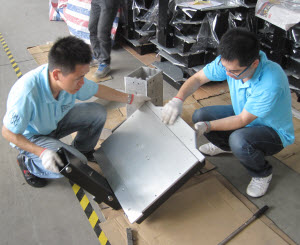

ASSEMBLY INSPECTION

The purpose of this inspection is to verify that all of the necessary components have been inspected properly and are free from any noticeable damages and defects to ensure that all of the products that came out of the production queue are ready for the next inspection process. According to several quality control standards, each item must be thoroughly assembled to ensure that all of the items produced are ready prior to distribution.

VISUAL INSPECTION

The purpose of this inspection process is to verify that all of the cleaning supplies that have undergone the assembly queue are thoroughly inspected for any visible damages, defects or any production anomalies to ensure that all of the items are ready for the next inspection process. Here are some of the specialized visual inspection processes for different types of cleaning supplies:

- Brooms– depending on the type of broom and its cleaning material, brooms will be thoroughly inspected regarding its condition, shape, size, mechanism (if applicable) and rods to ensure that all of the items are inspected to meet quality control standards.

- Mops– depending on the type of mop and its head, mops will be thoroughly inspected by its cloth quality, thread count, self-squeeze mechanism(if applicable), rotary mechanism (if applicable) and other necessary components to ensure that all of the products are free from any visible damages, defects or production anomalies prior to distribution.

- Mechanical Cleaning Devices– vacuum cleaners and floor polishers are among the many electrical cleaning devices we have today. Each part of the mechanical device will be thoroughly inspected for any loose wiring, chip malfunctions and other anomalies to ensure that all of the cleaning devices are ready for the next inspection process.

- Bins, Garbage Cans and Dust Pans– depending on the quality and materials that was used during the assembly, each product will be thoroughly inspected for any cracks, damages or blisters and any production anomalies to ensure that each cleaning supply is free from defects prior to distribution.

- Rugs and Other Cloth Materials – each cleaning supply will be thoroughly inspected according to its product specification. Each product will undergo a thread count test and as well as fiber tests to ensure that all of the cleaning supplies adhere to the quality and safety guidelines. If any defect product was found during the production queue, items will be sent to the first process to save time.

WEIGHT AND MEASUREMENT INSPECTION

The purpose of this inspection process is to verify that all of the materials of the same classification have the uniform product specifications to ensure that all of the cleaning supplies are uniform in height, length, width, weight and diameter as per quality control standards. Items that fail this inspection process will be considered “defective” and will not be distributed.

STRUCTURAL INTEGRITY INSPECTION

The purpose of this inspection process is to verify that all of the cleaning supplies on queue are structurally sound. Each cleaning supply on queue will undergo a series of stability tests to ensure that all of the products are accurate and ready for the next inspection process. Items that fail this inspection process will be returned to its corresponding department to determine if any solutions can be done prior to marking the product as “defective.”

[sidebar name="case studies"]

MECHANICAL INSPECTION

The purpose of this inspection process is to verify that each of the mechanisms of the electrical cleaning devices are attached and soldered correctly to ensure that all of the necessary components needed for the electrical device to run is working as expected prior to having it tested during the final inspection process. Products that fail the inspection process will be taken back to the assembly queue to verify which wiring or chip malfunctioned to save time on the overall production.

FINAL INSPECTION

The purpose of this inspection process is to verify that all of the cleaning supplies that have undergone the series of inspections are ready to put to use. Each cleaning material, regardless of its class, will undergo a series of tests to determine if the product is reliable and ready for shipping and distribution. Here are some of the tests involved during the inspection process:

- Non-Mechanical Cleaning Tools– brooms, mops and cloths will be tested via a battery test wherein the products will undergo specific tests to verify that the cleaning supply being tested is doing its intended purpose. Items that fail the final inspection will be labeled as “defective” and will be disposed of.

- Mechanical Cleaning Tools– since each mechanical tool has its own intended use, each item will undergo a series of battery tests to ensure that all of the mechanical tools being tested are working accordingly. Here are some of the examples of tests being done on certain cleaning tools:

- Vacuum Cleaners– these devices will be put to the test in terms of its capability to draw test materials with its vacuum power and its capability to operate on extended periods of time in compliance to its product specifications.

- Floor Polishers – these devices will be put to test via a series of floor polishing tests on different surface to ensure that all of the known floor surfaces can be cleaned in compliance to its product specifications.

- Air Duster – these devices will be tested in terms of its blowing capacity and its effectiveness on tight seams to ensure that its blowing power is capable of delivering its intended use in compliance to its product specifications.

- Trash Bins, Cans and Dust Pans – these special cleaning supplies will be tested by its weight capacity, storage capacity and structure strength to ensure that all of the items are heavy duty as per the different international quality control guidelines. Items that show breakage or fail the standards will be considered “defective.”

- Cloths - microfiber, cotton and other types of cloths undergo a series of tests to verify its absorbing capabilities, effectiveness to wipe wet surfaces, capabilities to wipe of dirt and other known uses for cloths to ensure that all of the cloths being produced are more than ready for shipping and distribution.