Impact Coating Adhesion Testing

It's important that the coating on the cast iron is subjected to a certain amount of blunt force to determine the strength of the coating - a method called impact testing. The procedure for impact testing is simple, doesn't require any technical equipment or materials and you don't need to be an expert to do it. The only materials needed for impact testing are a 350g steel ball, a length of PVC pipe about 150cm long, a piece of double-walled cardboard and a ceramic-coated piece of cast iron cookware. The PVC pipe should have a diameter large enough for the ball to fall through without resistance and with little space around it.

Before starting the test, you'll want to know whether or not the cookware you're testing has what's called a drop circle. A drop circle is a recess in the bottom of cast iron pot or pan that causes a weakness in the coating. The recess is often cause by an impression left in the mold with the manufacturer's logo. It's important that you don't drop the ball directly on the drop circle because this is a weak point in the coating that is more likely to break and yield inaccurate results.

Now that you know the equipment you'll need, let's get into the procedure for coating adhesion testing step-by-step:

- Place the cast iron item, bottom-up, on the piece of double-walled cardboard on a hard floor.

- Drop the steel ball through the top of the PVC pipe directly onto the flat, exterior bottom of the item on 1 point around the drop circle. Be sure that the ball doesn't impact the item on the curved edge or side wall, since the coating is weaker on these areas.

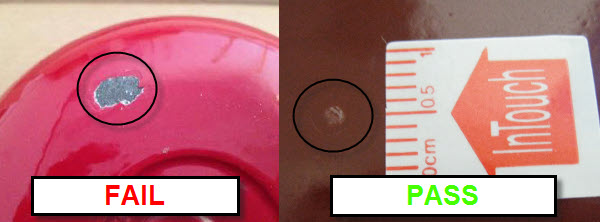

- After impact, examine the contact point, looking for any chips, dents, scratching, flaking or other damage to the surface enamel of the cookware item. A small dent in the enamel is acceptable. But if enamel falls away like an eggshell, chips away or shows damage in places outside the contact point, this item fails the test.

- Repeat the test on 3 more different points around the drop circle.

Impact testing is also conducted on the interior surface of the cast iron to assess coating adhesion. Testing the interior involves the same procedure, but you'll want drop the same steel ball from a lower height of about 70cm. Again, be sure to drop the ball at 4 points around the drop circle for accurate results. As with testing the exterior, you're likely to find at least a small, round dent or scratch in the coating, but it should be round, regular and only present on the point of impact.

Now that you know how to test coating adhesion like an expert, check out similar product inspection protocols for cast iron in this related article!