Major clothing brand American Apparel recalled over 10,000 children’s "sleep sacks" in May 2019 due to a burn hazard. The related clothing items failed to meet the U.S. federal flammability standard for children’s nightwear and could easily catch fire.

Major clothing brand American Apparel recalled over 10,000 children’s "sleep sacks" in May 2019 due to a burn hazard. The related clothing items failed to meet the U.S. federal flammability standard for children’s nightwear and could easily catch fire.

Although no injuries have been reported from the hazard yet, this recall has undoubtedly brought challenges for American Apparel. Insurance firm Allianz estimates the average product recall costs companies more than $12 million.

Clothing items aren’t typically considered “high risk” products. But flammability issues are one of the main risks clothing importers should be aware of. The U.S. Consumer Product Safety Commission (CPSC) estimates more than 4,000 people per year suffer severe clothing-related burn injuries, with about 150 annual fatalities.

From manufacturers to consumers, everyone in the supply chain can benefit from flammability tests for fabric and clothing. Here’s what you need to know as an importer to ensure the safety of your clothing products with flammability testing.

Why importers need to conduct flammability tests for fabric and clothing

Flammability is defined as the “characteristics of a material that pertain to its relative ease of ignition and relative ability to sustain combustion”. And as it applies to garment and textile products, flammability presents some serious risk to importers and consumers.

Most fabrics are inherently flammable to some degree, unless they’ve been treated with a chemical flame retardant. But the speed and degree to which a fabric burns can vary based on fabric:

- Fiber content

- Weight

- Construction

- Finishing

For instance, synthetic fabrics might melt, rather than burn, which can cause serious burns when they contact skin.

Most consumers don’t expect their everyday clothing to be fire resistant. But a fabric that burns too quickly can still endanger consumers.

And the consequences of a highly flammable garment are sometimes realized too late—when someone gets injured. Often the offending brand suffers reputational damage, costly product recalls and legal repercussions as a result. All can be prevented.

That’s why many fabric and clothing importers turn to  professional flammability testing to verify their product’s safety before shipping and distribution. A pre-shipment flammability test for clothing can help you:

professional flammability testing to verify their product’s safety before shipping and distribution. A pre-shipment flammability test for clothing can help you:

- Proactively assess your product’s flammability and prevent any issues before the goods reach your customers

- Offer proof to your customers showing your products are safe and reliable

- Ensure compliance with mandatory flammability testing standards for relevant markets and products

Mandatory flammability testing standards for fabric and clothing in the U.S. and Canada

The U.S. and Canada have implemented some of the strictest mandatory flammability testing requirements for clothing in the world.

The U.S. Flammable Fabrics Act (FFA) passed in 1953 regulates the manufacturing and sale of flammable clothing textiles in the U.S. The Act grants the CPSC the authority to issue mandatory flammability standards and remove highly flammable clothing or textiles from the market.

The U.S. flammability standard for clothing is detailed in the Code of Federal Regulations (CFR) in 16 CFR 1610.

Canadian flammability testing requirements for fabrics are detailed in the Hazardous Products Act (HPA). Canada follows the Canadian General Standards Board standard CAN/CGSB 4.2 NO. 27.5-94.

U.S. 16 CFR 1610

The U.S. 16 CFR 1610 standard applies to any textile fabric which is “in a form or state ready for use in wearing apparel”. Hats, gloves, footwear and interlining fabrics (the layer between an outer shell and an inner lining) are exempt from 16 CFR 1610 requirements.

In addition, importers of the following fabric types do not need to conduct flammability testing because the results tend to be consistent for each:

- Plain surface fabrics, regardless of fiber content, weighing 2.6 ounces per square yard or more; and

- All fabrics, both plain surface and raised-fiber surface textiles, regardless of weight, made entirely from acrylic, modacrylic, nylon, olefin, polyester or wool or any combination thereof

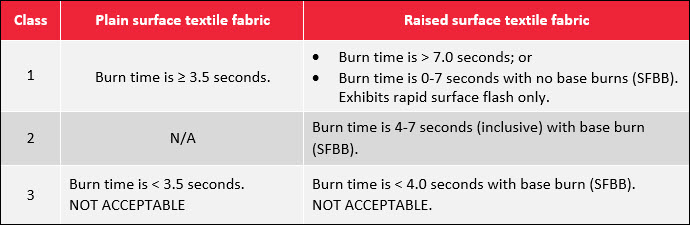

16 CFR 1610 flammability test procedures classify textiles as follows:

- Class 1 – Normal flammability: these textiles fully meet the highest requirements of the standard and are acceptable for use in clothing.

- Class 2 – Intermediate flammability: these textiles are more flammable than Class 1 but still meet the requirements of the standard and are acceptable for use in clothing. This classification only applies to raised-fiber surface textiles.

- Class 3 – Rapid and intense burning: These textiles are dangerously flammable and cannot be used for clothing in the U.S. These samples fail to meet the requirements of the standard.

The testing acceptance criteria are different for plain surface textile fabrics and raised surface textile fabrics.

Plain surface textile fabrics are any textile fabrics which do not have an intentionally raised fiber or yarn surface such as a pile, nap or tuft. Fabrics with fancy woven, knitted or flock-printed surfaces are still considered plain surface textiles. Raised surface textile fabrics are any textile fabrics which do have an intentionally raised fiber or yarn surface.

U.S. 16 CFR 1610 flammability test procedures

The 16 CFR 1610 flammability test procedure includes:

- Testing in the original state

- Testing after refurbishing (dry cleaning and laundering)

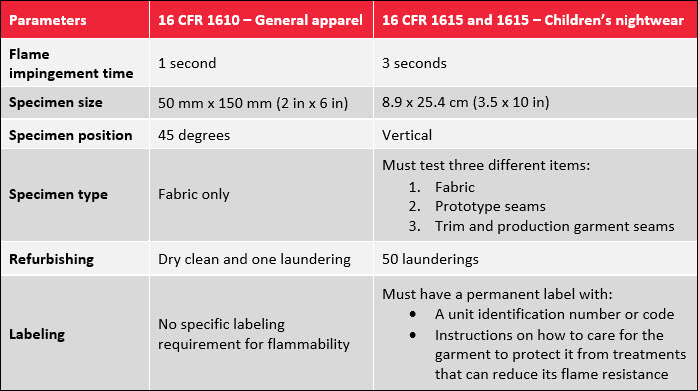

16 CFR 1610 test sequence criteria require testing five specimens cut from a sample of fabric and testing another five specimens in the event of a short burn time. Each specimen must measure 50 mm x 150 mm (2 in x 6 in).

When performed in a professional laboratory, this flammability testing uses a specialized flammability test chamber, where the specimen can be angled at 45 degrees on an apparatus. A flame is applied to the surface near the lower end of the specimen for one second.

A lab technician records the time required for the flame to spread up the fabric a distance of 127 mm (5 in) and classifies the fabric according to the standard:

U.S. and Canadian flammability test procedures are largely identical. The major difference is Canada only accepts fabrics with a burn time greater than but not equal to (>) 3.5 seconds and 4 seconds for plain surface and raised surface textiles, respectively.

U.S. and Canadian flammability test procedures are largely identical. The major difference is Canada only accepts fabrics with a burn time greater than but not equal to (>) 3.5 seconds and 4 seconds for plain surface and raised surface textiles, respectively.

The U.S. has a slightly lower tolerance, accepting fabrics with a burn time greater than or equal to (≥) 3.5 seconds and 4 seconds, as shown above. There are also some minor differences in laundering requirements between the two standards.

U.S. 16 CFR 1615 and 1616 for children’s nightwear

There are stricter requirements for children’s nightwear in the U.S. and Canada, as well as in some other markets.

In the U.S., children’s nightwear must be flame resistant and self-extinguish if a flame from a candle, match, lighter or a similar item ignites it. The children’s nightwear standard measures the char length of the fabric, rather than the burn time:

- The average char length of five specimens cannot exceed 17.8 cm (7.0 in)

- No individual specimen can have a char length of 25.4 cm (10 in)

U.S. flammability testing requirements for children’s nightwear are detailed in 16 CFR 1615 for children’s nightwear sized above 9 months and up to 6X, and in 16 CFR 1616 for children’s nightwear sized 7 through 14. The requirements are essentially the same for both.

Babies’ nightwear under 9 months is not regulated under the standard, as infants are not likely to be left unattended near a fire. But these garments must still meet the requirements of 16 CFR 1610. Tight-fitting nightwear designed in line with CPSC dimension requirements is also not regulated under 16 CFR 1615.

16 CFR 1615 flammability test procedures differ from 16 CFR 1610 requirements in a few major ways:

In Canada, flammability requirements for children’s nightwear are detailed under item 40 of Part II of Schedule I in the HPA. The acceptance criteria for children’s nightwear in Canada are the same as those in 16 CFR 1615.

In Canada, flammability requirements for children’s nightwear are detailed under item 40 of Part II of Schedule I in the HPA. The acceptance criteria for children’s nightwear in Canada are the same as those in 16 CFR 1615.

Voluntary flammability test procedures

As of 2019, the EU has only implemented voluntary flammability testing requirements for clothing. But compliance requirements are always subject to change. EU importers can prepare for any regulatory changes by proactively ensuring product safety using internationally recognized flammability test procedures.

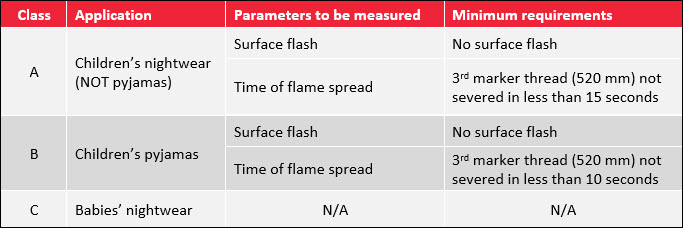

EN14878 for children’s nightwear

EN14878 sets flammability standards for children’s nightwear in the EU. EN14878 is a voluntary standard and is not harmonized into national legislation across the EU. EN14878 has not been made a mandatory benchmark due to the potential toxicity risks of flame retardants in children’s clothing.

EU importers should conduct testing according to EN14878, rather than 16 CRF 1610, if they want to demonstrate compliance, as the requirements are different.

Like 16 CFR 1615, EN14878 doesn’t apply to babies’ nightwear. But EN14878 has a lower minimum age limit—garments intended for children 6 months or older are covered under the standard, vs. 9 months or older in the U.S. standard.

EN14878 also distinguishes between “nightwear” and “pyjamas”. Nightwear can include nightdresses, bathrobes and dressing gowns, while pyjamas are typically tighter-fitting garments worn to sleep.

EN14878 measures the time of flame spread, like 16 CFR 1610, but does so differently:

There is an amendment to the standard for the UK, as parts of EN14878 are less stringent than the requirements of the existing UK Nightwear (Safety) Regulations 1985. So UK importers should continue to comply with UK regulations where the standards deviate.

There is an amendment to the standard for the UK, as parts of EN14878 are less stringent than the requirements of the existing UK Nightwear (Safety) Regulations 1985. So UK importers should continue to comply with UK regulations where the standards deviate.

The UK regulation also applies to adult nightwear, while the EU standard does not.

ASTM D1230: 45-degree burn test

ASTM International, formerly known as American Society for Testing and Materials, is an international standards organization that develops voluntary testing standards.

The ASTM D1230 flammability test procedure for apparel textiles is very similar, but not identical, to the flammability test procedures outlined in 16 CFR 1610. Therefore, ASTM D1230 may not be used to demonstrate compliance with 16 CFR 1610 for commercial sale in the U.S.

But ASTM D1230 can still be helpful for evaluating the flammability of non-regulated apparel items, such as for markets without a mandatory standard.

ASTM D6413: vertical burn test

The ASTM D6413 flammability test procedure is used for measuring textile flame resistance. ASTM D6413 measures the char length of a flame-resistant (FR) textile but does not set a pass/fail standard for flammability.

ASTM D6413 flammability testing procedures are incorporated into the National Fire Protection Association’s (NFPA) NFPA 2112 standard, which does set pass/fail requirements. NFPA 2112 is primarily used to test flame-resistant textiles, such as apparel worn to protect wearers from exposure to flash fires in the oil, gas, chemical or petrochemical industries.

Can you rely on your supplier to conduct flammability tests for fabric and clothing?

Most clothing importers don’t rely on their supplier to conduct flammability tests for clothing because:

conduct flammability tests for clothing because:

- These tests often require specialized equipment and personnel that the factory might lack. Most fabrics are inherently flammable, and accurately measuring the degree of flammability requires expertise.

- Factory staff might “cherry pick” samples which they know will meet standards and aren’t representative of actual order quality. Your supplier might choose a sample of a higher-quality fabric than they intend to use in production for the sake of obtaining favorable test results.

Instead, you might hire a third-party inspector to visit your supplier’s factory and randomly pull samples from production. This inspector can send the samples to a qualified laboratory for testing.

The laboratory can then issue a professional report that you can use to demonstrate compliance to customs officials and your customers.

With test results, U.S. importers can also issue a Continuing Guaranty with their product declaring that the product conforms to applicable flammability standards to retailers, distributors or manufacturers.

While not a mandatory legal requirement, some retailers might require a guaranty because it relieves them of any criminal prosecution resulting from flammability problems with the products.

The guaranty must be based on “reasonable and representative tests conducted in accordance with applicable flammability standards issued under the Flammable Fabrics Act (FFA)”. And a failure to maintain professional testing records could result in civil liability or criminal prosecution.

Conclusion

Importers should always check for any applicable regulations for their product before importing into their target market. There are other standards for bedding and other home textile products not detailed in this article, for instance.

Government websites like the CPSC website and the EU’s consumer safety website are a good place to understand your compliance requirements. There you can read about current recalls, learn about applicable regulations and monitor regulatory updates.

A third-party inspection and lab testing provider can also help you understand applicable regulations for your product. Once you’re ready to test your product, your provider can help collect samples, test them in a professional laboratory and issue you a report.

This level of oversight minimizes your regulatory risk and assures your customers of your product’s safety. Flammability testing for fabric and clothing is a win-win for everyone in your supply chain.

How do you conduct flammability tests for fabric and clothing? Share your experiences in the comment section below!