Implementing the best possible eCommerce quality control methods is a must when shipping products directly to consumers. Here are three important garment inspection sampling methods that can help your eCommerce business minimize returns by identifying defective or damaged products before accepting and selling items from a particular lot.

Reduce Returns With Top-Notch eCommerce Quality Control

Products are often returned because they are defective, the packaging is damaged, or for other quality-related reasons. Typically, these products cannot be resold and the result is lost revenue. These types of defects also give customers a negative impression of your business, which can result in further revenue loss if they choose not to purchase from your business again.

Fortunately, most of these returns can be prevented by implementing various types of quality control to identify and remove defective or damaged products from your inventory before they are sold. Among the quality control methods, inspection is the most-frequently used service and AQL standard is the most common way to select a sample for visual or appearance review.

3 Garment Inspection Sampling Methods Using AQL Standard

Sampling with AQL yields results based on statistics, from which importers can make more informed decisions about accepting or rejecting the goods. Below are three common AQL inspection methods:

1. Single-sampling plans

Single-sampling plans are based on the results of one random sample. The sample size is fixed and determined by a combination of the chosen AQL, desired inspection level and the total order quantity. This method is most commonly used in the QC inspection industry because it’s simpler and often more efficient than other sampling plans.

2. Double and multiple-sampling plans

In double-sampling plans, the inspector begins with two sample sizes that each have a unique accept and reject point for the order. This method allows you to re-inspect when the results of checking the first sample are questionable. If you come to a conclusion using the first sample size, then double-sampling can reduce your QC inspection costs.

Multiple-sampling plans are similar, but use up to 7 samples to reach a conclusion. The main advantage of this method is that the sample sizes are relatively small.

3. Sequential-sampling plans

Unlike single, double and multiple-sampling plans, the sample size for sequential-sampling plans isn’t fixed. Rather, you’d typically inspect a sample of 1 unit at a time until you’re confident you can accept or reject the order. The advantage is that it can be quicker to find defects using this method.

3 Alternative Garment Inspection Sampling Methods

Though well-liked by quality control industry, AQL may not always be the best standard for all importers. Ecommerce brands should also consider alternative sampling methods to see what works best. Here are some popular alternatives:

- Arbitrary Sampling

Significant quality issues affect a large portion of a lot of garments, rather than just one or two pieces, which means they are the most important problems to identify. Arbitrary sampling involves inspecting a random 10 percent of each completed lot to determine whether the entire lot will be accepted or rejected. This is the most common sampling method among garment manufacturers.

2. Spot Checking

Spot checking is similar to arbitrary sampling, but it has no set numbers or percentages of products that need to be inspected. Instead, inspectors test as many garments at random as they feel are necessary to determine acceptance or rejection. This sampling method tends to be the easiest to implement at any stage of the inspection process, rather than waiting until the garments are completed, as no set criteria need to be followed as far as determining sample sizes.

3. Acceptance Sampling

Acceptance sampling uses ISO 2859-1:1999 as a guide for determining specific sample sizes based on lot sizes, as well as the specific standards for deciding whether a particular lot will be accepted or rejected. This method can be used at any stage in the production process, such as raw materials before production begins, during production, and final inspection after products are finished.

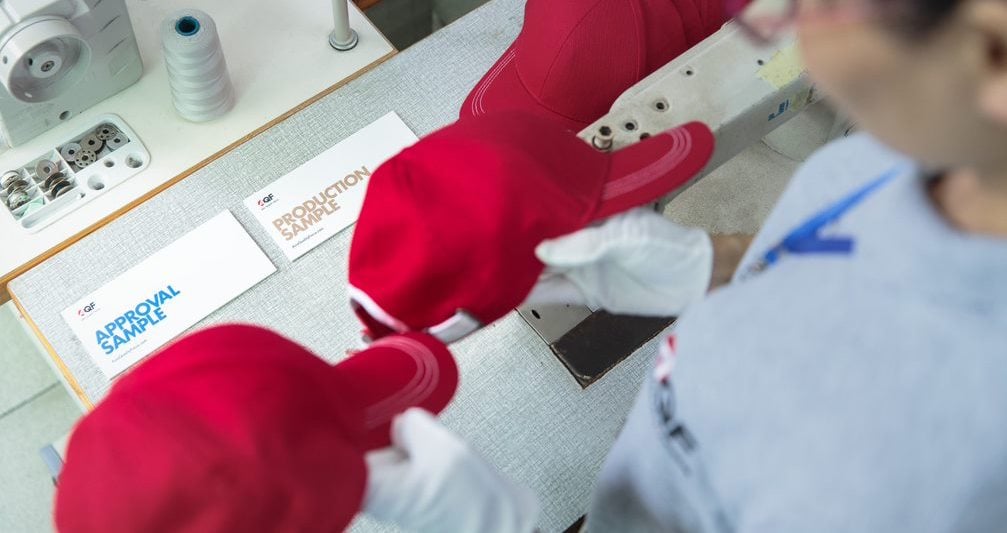

Direct-to-Consumer Quality Control Services

Thorough garment inspection is a must when it comes to minimizing preventable returns. Implementing the right sampling methods helps to ensure that defective products do not reach the marketplace and tarnish your brand’s image. Contact Asia Quality Focus today to learn more or to request a demo!