Best in Manufacturing – October 1, 2017

Each Sunday, we publish a list of top articles and other content related to manufacturing in areas like quality control, product development, supply chain management, sourcing, auditing and law.

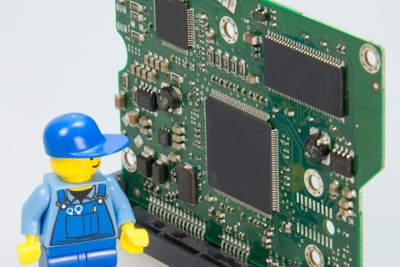

1. Lego-like integrated circuits: a new opportunity for manufacturers?

When I was a kid I loved Legos. In fact, I still think they’re pretty cool…although I don’t sit at home and play with them for hours on end like I previously did. Nowadays, it looks like the niftiness of Legos is about to translate into value for those manufacturing electronic devices.

Researchers at the King Abdullah University of Science and Technology have developed technology that converts integrated circuits into circuits that are similar to Legos in that they have an easy snap-into-place-like capability. The author of this featured article believes the development,

Researchers at the King Abdullah University of Science and Technology have developed technology that converts integrated circuits into circuits that are similar to Legos in that they have an easy snap-into-place-like capability. The author of this featured article believes the development,

…could ease the manufacturing process, enhance the production rate, and reduce the failure rate of the micro-scale interconnects.

My mind races with all the potential applications that could come about with Lego circuits.

Imagine if robots could, en masse, simply apply a little pressure to Lego-like modules on a PCB to complete that portion of assembly. Or imagine if companies use this technology to make modular wearable electronics, phones or other gadgets – you buy a base item and then build it up using the electrically capable Lego technology.

All this talk of Legos is making me want to find my storage container at home that’s full of them. While I search for that, you can check out the full article that talks about Lego electronics in the link below:

'Lego-Electronics' Offer Simple Way to Assemble Integrated Circuits – Lisa Zyga, Tech Xlpore

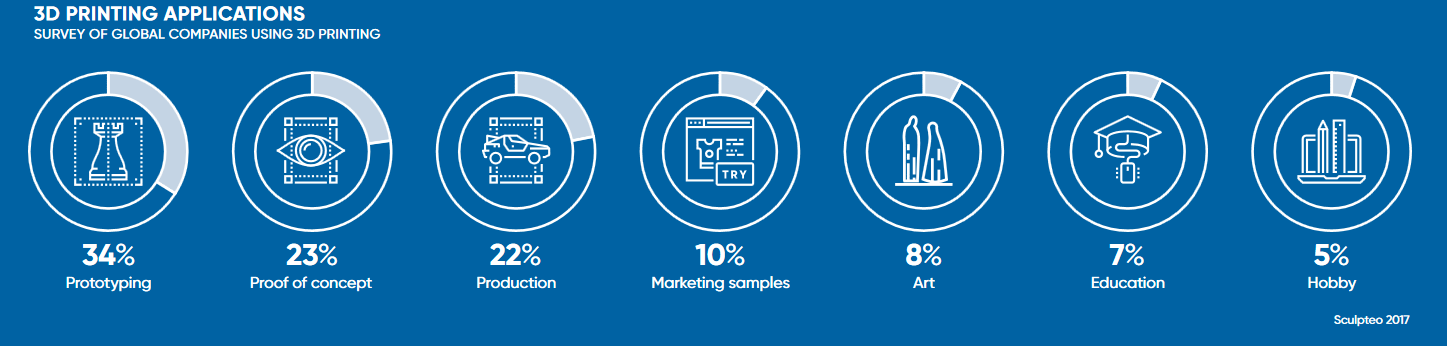

2. 3D printing’s industrial proliferation [Infographic]

Additive manufacturing, also known as 3D printing, is a hot topic in manufacturing and in society in general. On an individual level, there’s talk that hobbyists will have the ability to print all sorts of items, like toys, tools, trinkets and more. And on the industrial level, additive manufacturing could revolutionize mass production if it’s able to scale and rival current production methods.

Yet for all this excitement and hype, is 3D printing really doing anything worthwhile at the moment? That’s ultimately up for you to decide. But I’ll leave you with some interesting 3D printing achievements and a small snapshot of the infographic contained in this featured article to help you make up your mind.

- Boeing might save $3 million in costs per plane due to 3D printing

- NASA 3D printed a wrench in space

- Some researchers have 3D printed human body parts

Here’s a quick peek at how 3D printing is being used:

Do you think 3D printing is already providing great value to society and industry or do you think it still needs time to mature? Let us know in the comments section at the bottom of this page.

Be sure to check out the full infographic that covers how manufacturers, in particular, are using 3D printing by following the link below:

3D Printing Is Finally Changing the Manufacturing Landscape – Jeff Desjardins, Visual Capitalist

3. Adhesives for reusable medical devices

When you go to a hospital, whether it’s for a serious or minor issue, you’re probably hoping that the doctors and nurses know what they’re doing. But what if you also had to worry about whether the doctors were using medical products and devices of acceptable quality?

Thankfully, standards exist for managing the quality of medical devices, like ISO 13485:2016 and ISO 10993-5. But as this featured article points out, there’s also plenty to consider when it comes to how to manufacture medical devices that will adhere and stay together in a clean, reusable way.

For reusable medical devices like surgical instruments, implantable devices and catheters, the chemical composition of adhesives is a critical consideration. These devices will need to hold up during intense sanitization using steam, chemicals or irradiation. And plastic materials used in production of the device potentially require a pre-treatment primer to ensure that adhesives bond sufficiently. You also need to consider at what temperature curing should take place.

For reusable medical devices like surgical instruments, implantable devices and catheters, the chemical composition of adhesives is a critical consideration. These devices will need to hold up during intense sanitization using steam, chemicals or irradiation. And plastic materials used in production of the device potentially require a pre-treatment primer to ensure that adhesives bond sufficiently. You also need to consider at what temperature curing should take place.

I personally can’t imagine that making medical devices is very easy. But at least with this featured article, you can gain more insight into one aspect of their design and development. To read more about this topic, check out the article in the link below:

Using Adhesives in the Design and Development of Medical Devices – Kagan Pittman, Engineering.com

4. What belongs to whom: product ownership and your Chinese supplier

“This is our product”, says your Chinese supplier, to which you respond, “No, this is OUR product.” This back-and-forth argument could continue for hours on end. At the end of the day, you might just say “Enough of this, it’s my product, I’ll do with it what I want” and go to a different supplier with the expectation that the new factory can make the product.

There’s certainly the possibility that the new factory you’ve found is capable of making the product. But the real, looming question is: are you stuck with the original factory for production of that exact product?

This featured article explores that question by looking at the situations in which you find yourself changing suppliers and trying to continue production of “your” product. If your original factory really just customized their design to have your logo, for example, you might find yourself paying them a royalty if you want a different factory to produce that item.

If you designed the product, the situation might be a little different. Yet in other cases, importers fall prey to the idea that just because a factory started to make orders with their branding, the product in its entirety is automatically theirs.

Make no mistake: the branding is yours. But if you’re just adding the branding, the design is likely still the supplier’s (this might vary based on the manufacturing agreement you have).

Want to find out what to do in a situation like this? Check out the full article in the link below to learn more:

China Manufacturing: Are You Stuck? – Steve Dickinson, China Law Blog

5. Where China stands in the global economy and where it’s headed

Looking for a comprehensive overview of China’s place in the global economy? Look no further than this featured article.

This article provides a detailed analysis of China’s economy, but the key points for importers and manufacturers rest in what it says about trade fairness with China.

China has been a member of the World Trade Organization since 2001, but several countries still don’t recognize it as a market economy due to its government intervention in economic policy. While trade barriers exist within the WTO to preserve fair trading among its members, China has circumvented these barriers by signing bilateral agreements with specific countries. Some of the stipulations of those treaties are that the other signatory must acknowledge the “One China” policy and that China is a market economy.

The important point raised by the article is that China therefore constantly continues to push for “lower tariff barriers on goods in potential markets”. If they’re successful in attaining more favorable trade policies, this could mean better prices for your Chinese competitors in your target markets.

With the insight offered by this article, you can better understand China and whether it’s right for your importing business. Check it out by following the link below:

Trade Profile: China Stands Its Ground – Editorial staff, Stratfor

We’re constantly scanning the web for top manufacturing stories and news. If you’d like to submit an article for consideration for our weekly Best in Manufacturing, send us a message and let us know.