The Difference Between Product Certification and Product Inspection

Product certification and product inspection are two distinctly difference services from the perspective of an inspection firm. Product certification is conducted by submitting a product sample to an accredited laboratory which then verifies that the submitted item complies with some specified regulation. Product inspection, on the other hand, can be conducted internally by the manufacturer or by the buyer or a third party to verify that production meets specific quality standards.

Even though these services are very different, many buyers still wonder...

Can Product Certification Be Checked During Inspection?

In theory, the answer is YES. Given an explicit list of physical requirements for an item, an auditor can perform tests to make sure that the item meets the requirements set forth by the certification body.

In practice, the answer is almost always NO for two main reasons:

- Inspections are mostly carried out in uncontrolled environments (factories, warehouses, etc.) with tools that may or may not be precisely calibrated; and

- Most importantly, inspectors typically are not recognized bodies qualified to verify certification.

Despite this, there are many ways to check, albeit roughly, if a product is compliant, in addition to product certification. For electrical items, the first way is to verify the item’s Component Data Form (CDF) during every inspection. A second way is to check the assembly of specific parts that are most likely to cause a serious problem. While a third-party inspection company may not be accredited by the certification body that sets the standards, they may be familiar enough with the standards to provide some assurance as to whether or not your product meets them.

Example Product Certification Checks for British Standard Plugs

Let’s return to the example mentioned earlier - you need to know if your blender has a British Standard (BS) plug. For sellers of electrical products in the UK, Ireland, and some former British territories, one of the most basic regulatory requirements they must meet is that the power plug must be a 13 A fused plug that complies with BS 1363. These plugs are renowned for being much larger than, say, an American plug but are significantly safer. Not surprisingly, the regulations the BS plug must comply with are much stricter.

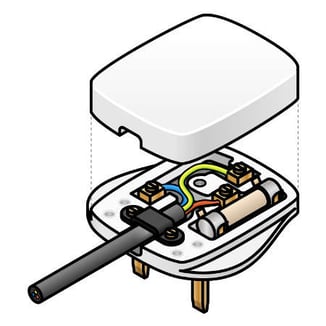

BS plugs are 3 pronged with 2 live pins (the line and neutral pins) and 1 grounding pin. This grounding pin is also used to “open” sockets, which have shutters that keep 2 pronged plugs (with no grounding pin) or other foreign objects from being inserted into the socket. BS plugs also have their own internal fuses (with their own regulatory requirements) that add an extra layer of protection against surges.

Checks for BS plugs include checking for the presence of:

Checks for BS plugs include checking for the presence of:

- Certification marks from one of 3 approved bodies on the plug itself (this is different than the certification marks on the product).

- Insulating sleeves (black or white sheathes) on the line and neutral pins to minimize the risk of a shock when pushing the plug in. Insulating sleeves are not allowed for earth pins.

- A side entry cable instead of a top entry cable, to make it difficult to unplug by tugging on the cable, which is an unsafe practice.

- A BS 1362 cartridge fuse with ratings of 13, 10, 7, 5, 3 or 2 amperes. This fuse should also have its own certification marks, usually from BSI or ASTA.

These checks are all relatively simple and easy to perform, but can be invaluable in catching serious compliance errors early on.

Conclusion

The people who inspect your product are not necessarily the same as those who are qualified to certify your product. A third-party inspection company is often familiar with product certification standards. They can perform some checks that might reveal if your product does not meet them, but they cannot ultimately certify your product. If you want to be 100 percent sure that your product meets all standards for certification, the best course would be to discuss this with your QC inspectors and consult a compliance expert or an accredited lab that can perform product certification. There is value in having your inspectors run checks for verifying standards to catch gross errors, but these checks cannot replace sending a product sample to a lab or other certified professional for verification.