Have you ever had difficulty scheduling a product inspection or factory audit through a third-party? Have you received a product inspection report that was missing some key requirement or process for checking your goods?

Have you ever had difficulty scheduling a product inspection or factory audit through a third-party? Have you received a product inspection report that was missing some key requirement or process for checking your goods?

Many importers express frustration when an inspection or audit cannot be booked on a certain date or a certain test is not completed on-site. But what many don’t realize is that the supplier actually plays a major part in controlling many aspects of the interaction with their third-party.

In fact, you might be surprised by what your independent auditor CAN and CANNOT do regarding scheduling and conducting a service on your behalf.

It’s important for you to understand what factors your QC company can’t control so that you can address those with your supplier directly and avoid costly quality issues, shipping delays and other undesirable effects of losing control of production.

1. The supplier allows access to the factory

Perhaps a more obvious aspect your QC company can’t control is access to the factory. Any inspection or audit at a facility requires consent from factory management and staff. It may sound like a straightforward concept, but it’s one that deserves a bit more attention. If you’re working with a trading company, for example, your supplier contact is probably not at the factory. And although he or she may agree to allow inspection, staff at the factory might not.

"If you’re working with a trading company, your supplier contact is probably not the factory."Providing the factory address

In some cases, the address you provide to your QC company contact may not be the actual factory address where the inspection is meant to take place. This is especially common when working through a vendor or trading company that does not reveal the factory to you upfront. It’s your supplier’s responsibility to provide your third-party with the actual factory address prior to scheduling.

Some suppliers are reluctant to give the address of the factory, which may be a sign that they are trying to avoid inspection or an audit altogether. If your third-party QC partner informs you of difficulty in obtaining the factory address, press the supplier to provide it.

Another suggestion is to send an email to your supplier with your QC company contact in CC, introducing the two parties. This way, there’s no uncertainty from the supplier about who will be carrying out the inspection or audit. It also helps to keep your inspection company in CC on any subsequent emails between you and your supplier. These added steps help to keep communication clear between all those involved and can prevent unnecessary delays.

Limiting access to specific areas in a factory

Once on-site, the factory staff will determine the areas your auditor can access. Often during a product inspection, factory staff will only allow access to two areas:

- The warehouse or storage area for completed products and

- A separate area where inspection takes place, typically isolated from the production area.

An inspector will usually arrive at the factory, go to the finished product storage area, verify product quantities, pull samples and head to the designated inspection area. Auditors are generally not permitted to walk freely around the factory and are usually accompanied by factory staff at all times.

You may have specific requests that require an inspector to visit other areas, such as requesting photos of specific production processes at work. If so, you should notify the supplier ahead of time, and factory staff will need to grant access during the service.

2. The supplier sets the service date for an inspection or audit

Often an importer will mistakenly assume that it’s the QC company that sets the date for the service. But actually, it’s the supplier that dictates to the QC company when the service will occur—if at all. While your QC partner will certainly try to accommodate the date that you specify for an inspection, it’s ultimately the supplier’s decision to confirm the booking.

Generally, the steps to scheduling a service are as follows:

- You introduce your QC provider to your supplier and advise them that you want an audit or inspection

- The QC company then sends a booking form to your supplier that requires entering a requested service date and other information

- The supplier sends the completed booking form back to your QC company and a phone call confirms the service date

You may have told your QC partner that you need inspection to occur on or before March 10th because your order is scheduled to ship on the 12th. But if your supplier issues the completed booking form with the 13th as the requested service date, the QC company must inspect on that date unless the supplier revises the form and resubmits it with a new date.

If your auditor visits the factory at a date other than that shown on the booking form, it’s very likely that they will turned away. This unsanctioned visit might also complicate your relationship with the supplier and cause more problems than it’s worth. So make sure that all parties agree in advance.

A professional QC company will try to book well in advance of the service date you propose. And your contact there will inform you of the date the supplier agrees to so that you can ask the supplier to revise it if needed.

3. The factory provides access to special inspection equipment

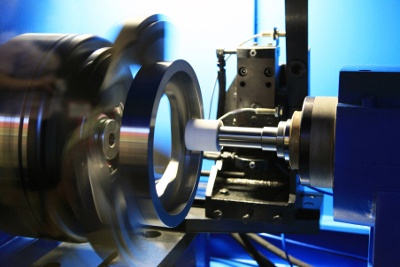

Auditors typically carry a set of tools and equipment with them to any factory where they conduct an inspection (related: 6 Essential Tools for Product Inspection). But for some inspections, other more specialized equipment is needed to check certain aspects of your product.

For precision machined components, for example, radius fixtures or thread gauges are necessary to properly check the items. Auditors generally do not carry this equipment on-hand and are reliant on the factory to provide it for inspection (related: 5 Factory-Provided Product Inspection Tools). A QC company can’t control this aspect of the service related to equipment availability.

For precision machined components, for example, radius fixtures or thread gauges are necessary to properly check the items. Auditors generally do not carry this equipment on-hand and are reliant on the factory to provide it for inspection (related: 5 Factory-Provided Product Inspection Tools). A QC company can’t control this aspect of the service related to equipment availability.

Sometimes a factory won’t have this equipment on-site, or their equipment is not properly maintained or calibrated for reliable use. Other times factory staff may not allow the inspector to use the equipment. As a result, you may see a remark in the inspection report you receive showing that a certain check, measurement or test was not performed because the necessary equipment was not available.

If you require particular equipment to be used for an inspection, be sure to check with your supplier before the service is confirmed to clarify that:

- The factory has the necessary equipment

- The equipment is properly calibrated and maintained, and

- The equipment will be available to the auditor for use during inspection

This seemingly minute detail can mean the difference between accurate reporting and uncertainty about your product.

"Your third-party has no control over the equipment the factory allows the auditor to use."4. The factory controls which on-site testing is conducted

A QC company can’t control which on-site testing is allowed during the service. Like the inspection equipment example above, on-site testing is another aspect of product inspection that your supplier dictates. And just as a factory can refuse access to certain equipment, they can also refuse to allow the auditor to conduct any particular on-site testing.

"A QC company can’t control which on-site testing is allowed during a product inspection."You’re more likely to see refusal from the factory staff to carry out destructive testing. An example of such testing that’s often refused is the carton drop test, routinely conducted to ensure the integrity of packaging and simulate normal shipping conditions. Because dropping a full  shipping carton can damage the packaging and the product itself, staff often refuse to allow the test.

shipping carton can damage the packaging and the product itself, staff often refuse to allow the test.

Other times a factory will only allow the inspector to open a certain number of units, which may not be the full sample size required for AQL. An example is testing for a product packaged in blister packs, where the item needs to be removed from the packaging for inspection and doing so will destroy the packaging.

If you require a particular on-site test to be conducted during product inspection, be sure to check with the supplier before scheduling the service to confirm that the factory will allow it. This is recommended especially in cases requiring destructive testing.

5. The factory provides required documents for audits

Factory audits tend to focus on the facility itself, rather than the product being manufactured therein. Regardless of whether an audit is checking quality management, environmental management, social compliance or some other area, the auditor will usually ask factory staff to provide certain documentation and records, which may include any of the following:

- Payroll records

- Financial records

- A business license

- An export license

- Various certifications

- A building permit

But quite often the staff will not allow the auditor to check certain documents or will say that they don’t have them. This sort of response might indicate the supplier is trying to hide something or is just generally resisting. And their refusal or inability to provide required documentation can result in failing the audit.

We suggest that you ask your auditor in advance about the scope of service, including the documentation that will be reviewed. Suppliers are sometimes uneasy about being audited, so informing them what the audit entails beforehand can help ease their anxiety. This should help ensure a smooth service for all parties.

Conclusion

Despite the potential benefits of hiring the help of third-party QC, there are several things your provider can’t control. While getting an inspection completed is usually a straightforward process, an uncooperative or uninformed supplier can make it more difficult or less successful.

You may want a particular supplier to fill an order—and they likely appreciate your business. But a product inspection or factory audit is often a vital part of that exchange requiring full cooperation from all parties. Ultimately you call the shots, and if the supplier inhibits the inspection service, you might be better off finding a new manufacturer.

If you'd rather listen to the interview that covers this topic instead, be sure to check out this manufacturing podcast episode!

Do you use third-party inspection to check your goods before they ship? Why or why not? Let us know in the comments below!