Best in Manufacturing – September 18, 2016

Each Sunday, we publish a list of top articles and other content related to manufacturing in areas like quality control, product development, supply chain management, sourcing, auditing and law.

1. Choosing the best place for small production runs

Going from prototyping straight to a factory in China for production might seem like an intuitive decision for some people. Once you finish designing your product, you might think “the time  has come” to start your first production run to see and feel what your product is really like. After all, if you’ve done due diligence and found a factory that can make what you want, why not use it?

has come” to start your first production run to see and feel what your product is really like. After all, if you’ve done due diligence and found a factory that can make what you want, why not use it?

In some cases, however, using a Chinese factory isn’t always the best option for small production runs when there are local fabrication houses available instead. These manufacturers are mostly helpful for people who have just finished prototyping and want to make only a few hundred units.

Before immediately using a Chinese factory for your manufacturing needs, consider these advantages of using a local fabrication house:

- Communication is easier: you speak the same language as the local fabricator;

- Time zone and proximity: you have access to real-time feedback and can visit the fabricator quickly due to how close it is;

- Shipping: you’re only shipping items over a short distance, which saves money;

- Engineering: speaking the same language as you also means the fabricator can provide solid engineering support

The decision where to make the first few batches of your product is ultimately up to you. You might have a great Chinese factory in mind that can conduct a small production run and handle the transition to mass producing your product. But your unique circumstances will dictate whether it’s better to manufacture locally or use a Chinese factory for your first run.

If you’d like to learn about the pros and cons of producing locally or abroad, check out more in the article below:

Does It Make Sense to Manufacture Smaller Runs in China or Locally? – Berkeley Sourcing Group

2. Global, connected manufacturing through the cloud

Today product ideas come to life faster than ever before, thanks to rapid prototyping technologies. But they’re still not made quickly enough to satisfy some companies.

Even with great new technology available, some businesses cannot achieve their desired time to market for some products. That’s because there are a number of bottlenecks in the manufacturing process, like the time it takes workers to move between machines when creating products.

But with the launch of a company called ZAP, that bottleneck might soon be long-forgotten.

What ZAP offers is a cloud platform that connects a wide variety of machines that can be used to seamlessly control manufacturing processes in factories around the world. Water jets, laser cutters, 3D printers and more are all controllable via the platform, which makes it easy for designers to create and tweak their products.

While the platform may sound nice, it looks even better. You can see the CEO of ZAP, John Dogru, describe it in his presentation at Tech Crunch’s DISRUPT event:

Dogru hopes to combine the entire workflow of the manufacturing process into one platform so that there’s no latency and companies can significantly reduce their time to market.

If you’d like to read more about ZAP, check out the article in the link below:

Zap Brings the Manufacturing Process to the Cloud – Brian Heater, Tech Crunch

3. Computer chip manufacturing improvements

Big changes to products aren’t always observable with the naked eye. In the case of recent improvements to the computer chip manufacturing process, the changes are on the nanoscale.

Engineers at the University of Wisconsin-Madison and the University of Chicago have devised a way to improve semiconductor functionality and data storage capacity. They accomplished this feat by using density multiplication and a self-directed assembly method that “[takes] advantage of a germanium wafer coated with a layer of virtually pristine graphene.” The sheet of carbon used in this process is just one atom thick.

Engineers at the University of Wisconsin-Madison and the University of Chicago have devised a way to improve semiconductor functionality and data storage capacity. They accomplished this feat by using density multiplication and a self-directed assembly method that “[takes] advantage of a germanium wafer coated with a layer of virtually pristine graphene.” The sheet of carbon used in this process is just one atom thick.

But how can importers benefit from these improvements in the way computer chips are made?

As the new method becomes more widespread, large-scale production costs of semiconductors might drastically decrease, which could result in cheaper prices for electronics. Components made with this method might also have fewer defects, making them safer and more reliable.

Although this new process hasn’t hit the mass market just yet, its potential to improve electronics is exciting and could lead to the next generation of super-products.

If you’d like to learn more about the improved manufacturing process for computer chips, check out the article in the link below:

New Computer Chip Manufacturing Method Squeezes More onto Limited Wafer Space – Renee Meiller, Phys.org

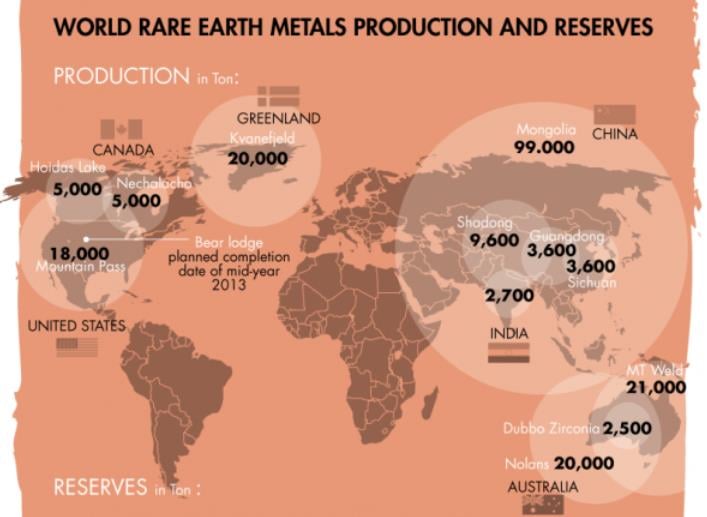

4. Infographic: the world supply of rare Earth metals

I've forgotten most of what I learned from chemistry class in high school. But when it comes to rare Earth metals, the 17 elements on the periodic table with a handful of remarkable properties, I remember one thing: they form the backbone of many important modern technologies.

A few examples of products that use rare Earth metals are televisions, solar panels, energy-saving light bulbs, camera lenses, magnets, shielding for nuclear reactors, sonar systems and more. The list goes on and on. Without rare Earth metals, these products most likely wouldn’t exist. And if there’s ever any shortage of them, you can expect the prices of components that need them to increase significantly.

Although the company is now out of business, Buckyballs created an amazing infographic that details many different aspects of rare Earth metals. You can take a look at a portion of it below:

If you’d like to see the entire infographic, check it out on Industry Week’s website:

All about Rare Earth Metals – Industry Week

5. Another advancement in automated garment manufacturing

A few weeks ago I wrote about OpenKnit, a company developing a low-cost and open-source digital fabrication tool for clothes. But there’s another tool for automated garment manufacturing on the market as well: Sewbo.

The Sewbo robot is comprised of a robotic arm and suction cup at the end. The suction cup picks up a piece of cloth that has been stiffened. While stiff fabric might sound like a problem, it actually helps Sewbo’s ability to control the sewing process.

The Sewbo robot is comprised of a robotic arm and suction cup at the end. The suction cup picks up a piece of cloth that has been stiffened. While stiff fabric might sound like a problem, it actually helps Sewbo’s ability to control the sewing process.

Once a garment has been picked up, Sewbo works in conjunction with a sewing machine to begin stitching it. After sewing is complete, all that’s required for the piece of clothing to lose its rigidity is a quick rinse in hot water.

While Sewbo still has a way to go before it can replace workers in factories, it’s another promising development for automated garment manufacturing. Someday it might lead to cheaper clothes with fewer defects. And if it’s truly a scalable technology, I think it could reshore garment manufacturing, leading to shorter order delivery times.

In the future, as Sewbo becomes more advanced and enters mainstream manufacturing, you might find a “Made by Sewbo” tag in the back of your t-shirt.

If you’d like to learn more about Sewbo, you can check out this video or the original article below:

Sewbo Robot Sews Up Automated Garment Manufacturing – Moritz Walter, Hackaday

We’re constantly scanning the web for top manufacturing stories and news. But if you’d like to submit an article for consideration for our weekly Best in Manufacturing, send us a message and let us know.