How did rejected products that you trusted your supplier to discard end up in a local market?

How did rejected products that you trusted your supplier to discard end up in a local market?

No factory is perfect. Most factories manufacture some goods that have defects or otherwise don’t meet your standards (related: How Experienced Importers Limit Product Defects in 3 Stages [eBook]). And you and your supplier have a few options for how to deal with rejected goods. But not all of those options are in your best interest as the importer. Like in the example above, you might find your rejected products are being sold to other customers—maybe even with your branding!

So what can you do to prevent this and other undesirable outcomes?

It helps to understand how your product can end up in unexpected places and what you can do to make sure they’re dealt with the right way. Here are four things your supplier might do with products you’ve rejected:

1. Shipping rejected products together with acceptable goods

For many importers, the most likely destination of defective products is their distribution center. That is, the factory is likely to pack any defective goods together with acceptable ones for shipping. The supplier may not even realize there’s a problem with some of the pieces they’re preparing to ship. But depending on the value of your  product and the number of unsellable pieces shipped, this can be a costly problem.

product and the number of unsellable pieces shipped, this can be a costly problem.

How bad can it be?

This may be less of a concern if you manufacture relatively low-cost products. But the manager of a factory producing jewelry or another more expensive item probably won’t want to discard valuable goods, even if they’re slightly defective. This highlights why initial supplier audit is so important: a trustworthy supplier won’t knowingly mix good and bad product quality together to sell to a customer (related: 5 Qualities of a Good Supplier).

It can be difficult for you to be sure of what your supplier will ship to you. Let’s say you carry out pre-shipment inspection of an order of earrings a week before it’s expected to ship. The inspection reveals a high number of defective pieces in the order. So you reject the defective goods and tell the supplier to replace them with acceptable ones before shipping.

But what’s to stop the factory from including the rejected goods in the shipment anyway?

Monitoring container loading to prevent shipping rejected goods

One of the best ways that an importer can be sure of what a factory ships is to monitor the container loading process. In most cases, the importer can personally observe or hire a third-party inspector to randomly check a certain number of pieces in an order as they’re loaded into a container for shipping.

This can serve a purpose similar to product inspection. The difference is that monitoring container loading assures the importer of what’s actually going into the container. The inspector can also note the number on the container seal, which the importer can confirm later when the container arrives at the destination port. This can prevent any confusion over how many defective pieces were shipped with an order.

2. Reworking/repairing defective products

Product rework or repairs carried out by the supplier can be important, since it’s often expensive to rework defective goods after you’ve received them. Aside from the labor cost you might pay for product repairs, lacking the necessary equipment can make it very difficult to repair defective goods yourself.

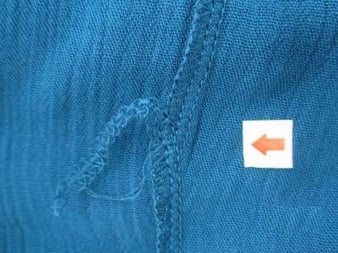

S ome defective products can often be reworked before shipping. Untrimmed threads found in garments, for example, are a defect that typically can be corrected by hand with a pair of scissors. Other issues, like the factory using an improper mold to make the product, might not be so easily remedied, and the goods may need to be replaced.

ome defective products can often be reworked before shipping. Untrimmed threads found in garments, for example, are a defect that typically can be corrected by hand with a pair of scissors. Other issues, like the factory using an improper mold to make the product, might not be so easily remedied, and the goods may need to be replaced.

When not to rework defective products

There may be times when there are quality problems that factory staff can rework, but you may not want them to rework because:

- You may be dealing with excessive shipping delays and prefer that the factory simply ship the goods as they are; or

- You’re concerned about any new damage or the potential for new defects associated with having workers handle the product again.

Deciding whether to rework products is ultimately a matter of weighing the pros and cons of the effort (related: 3 Vital Questions to Ask before Product Rework). Regardless of defect type, although a supplier may say that it will fix a certain problem, that doesn’t mean that it actually will.

"Product #rework can solve your quality problems or create even MORE. #mfg"Verifying product rework with inspection

When product inspection finds issues that can be reworked you might ask the supplier to address those. And you might also want to confirm the factory is actually following through with corrective action before the goods leave the factory. Re-inspection is typically the best way to check if defective products are still present in an order and in what quantities.

3. Selling rejected goods to other customers

One of the worst things that can happen to rejected products, from an importer’s perspective, is that they’re sold to other customers. Your supplier may work with other companies that manufacture similar products. If there’s a problem with your order, the supplier might sell part of it to these customers—potentially your competitors—at a  reduced price. And depending on your product, this may not be a concern for you.

reduced price. And depending on your product, this may not be a concern for you.

But this isn't all that could happen.

In some cases, your rejected products could end up being sold in the local marketplace. It’s one way for the supplier to turn a profit from what otherwise might be wasted goods. And stores in the country where your product is manufactured might welcome the inventory if they can buy it at a low price. This can be a problem if your brand remains on the defective goods sold because it can damage your brand reputation, especially if sold in your target market.

You’re more likely to encounter this in countries without strict intellectual property laws. For example, Chinese counterfeiting costs foreign firms about $20 billion in lost profits annually. If your defective goods are secretly sold, they may end up in this industry.

How can you prevent your rejected products from being sold?

4. Destroying rejected products

Although it may seem excessive, one of the best ways to ensure that rejected or defective products don’t end up being sold is to destroy them. How does that work?

Depending on the agreement you have with your supplier, you may have to first take ownership of the rejected goods by paying for them. Even if the goods aren’t in acceptable condition, paying for and destroying them can typically spare you the cost of shipping and disposal. At the same time, you can be confident the goods won’t end up on the open market.

S econdly, you should discuss an appropriate method of destruction with your supplier. For example, an importer of exercise gloves found an issue throughout the whole order. After talking with the factory, the two parties decided the best way to destroy the gloves was to put them through an industrial shredder.

econdly, you should discuss an appropriate method of destruction with your supplier. For example, an importer of exercise gloves found an issue throughout the whole order. After talking with the factory, the two parties decided the best way to destroy the gloves was to put them through an industrial shredder.

A different importer decided the best way to destroy their earbud headphones was by running over them with a large roller. The most appropriate method will usually depend on the type of product and how much the importer or supplier is willing to pay to destroy it.

Once you and your supplier have agreed on destroying the rejected products, how can you be sure the factory actually destroys them?

Overseeing destruction of rejected goods

It helps if you can be physically present during the destruction process to ensure it’s carried out in full. Of course, traveling to the factory or destruction site can be both costly and inconvenient. Instead, many importers prefer to hire a third-party to witness defect destruction. Typically, most third-party inspectors can provide this service as well as giving you a short report of the destruction and photos of the process and result.

However you decide to oversee destruction of rejected goods, it’s vital that you or someone you trust is there to observe and make sure the job is complete (for more on product destruction, see Product Destruction: The Importer’s Guide).

"Sending an agent to observe product #destruction keeps rejected products from hurting your brand"Conclusion

The world is full of good suppliers and bad suppliers (related: 5 Qualities of a Good Supplier). Some will be relatively open with you about any substandard goods and will work with you to take corrective action. But there are others that would put your brand name at risk by shipping you rejected goods or selling them to other customers.

It helps to be clear about your expectations upfront, conduct due diligence with pre-shipment inspection and discuss with your supplier the best way to address any rejected goods. Sending an authorized agent, like a company employee or third-party inspector, can help relay these expectations and make sure they’re met. Because when your brand is on the line, you need confidence that any rejected products are dealt with as you see fit.

And don't forget to check out the manufacturing podcast episode that covers this topic!

Be sure to check out a related article, 3 Ways to Handle Defective Products, to learn more about how experienced importers deal with defective goods.