Best in Manufacturing – January 8, 2017

Each Sunday, we publish a list of top articles and other content related to manufacturing in areas like quality control, product development, supply chain management, sourcing, auditing and law.

1. The revival of the Silk Road

The Silk Road was an ancient trade route linking China to a host of countries in the West. It spanned thousands of kilometers and was an amazing conduit of trade.

This trade corridor has seen peaks and troughs in activity over the centuries that it’s been around. But now, thanks to China’s One Belt One Road Initiative, the Silk Road is slated for permanent hustle and bustle.

This trade corridor has seen peaks and troughs in activity over the centuries that it’s been around. But now, thanks to China’s One Belt One Road Initiative, the Silk Road is slated for permanent hustle and bustle.

Evidence of the Silk Road’s reemerging prominence is the recent freight train trip from Yiwu, China to London, England. What’s amazing about this journey is that numerous other cities in Europe and China are also destinations. That means that goods from a variety of locales can travel on the rail line and bring countries closer together through commerce.

The author reports that China is serious about developing the Silk Road into a truly effective means of facilitating trade. He says,

In 2015, 44% of China’s engineering projects outside of China were in countries along the new Silk Road, rising to more than 52% in 2016. With US $4 trillion behind the project, this is soft power on a massive scale.

While the Silk Road is a geopolitical push and an attempt to expand Chinese influence, it’s also an opportunity to improve trade ties among all the countries through which the route runs. And hopefully, with better economic connections the world can focus more on unity and less on our petty differences.

To learn more about the modern Silk Road, check out the article in the link below:

China’s New Silk Road Is All Part of Its Grand Strategy for Global Influence – Anoush Ehteshami, theconversation.com

2. Japan’s smartphone comeback

When you think of smartphones, the iPhone from America or the Galaxy S from South Korea might be the first that come to mind. If you’ve traveled to Asia before, you might also be familiar with China’s Huawei phones. Yet despite these big players in the international smartphone market, there’s another country that’s eager for a share: Japan.

The author mentions how one company, Gooute, is using Chinese manufacturing capabilities coupled with Japanese design know-how to create a phone that it thinks can compete internationally. The phones are relatively cheap themselves, but they’ll also offer the Aratas Net service, which will serve as an ongoing source of revenue for the company.

By pursuing unique design and outsourced manufacturing, Gooute is embracing a new business model in the smartphone sector. And while the author mentions that companies like Fujitsu and Huawei are making waves in the Japanese cellphone market, this new model could give smaller players a chance at disrupting a market currently dominated by big players.

To learn more about this new model and how Japanese brands are using it, check out the full article in the link below:

Japan Mounts Low-cost Comeback in Smartphones – Fumie Yaku, NIKKEI Asian Review

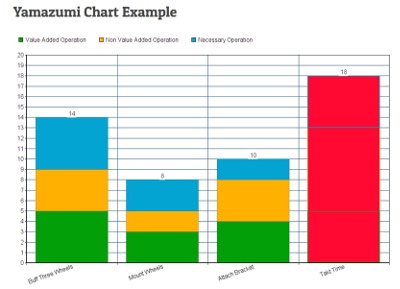

3. Yamazumi charts for better efficiency

Japanese manufacturing is well-known for its efficiency. The Toyota production system, for example, is a legendary contribution to the world from the Japanese masterminds behind it. A lesser known gift to manufacturing, however, is the Yamazumi chart.

The chart/board serves as an operator line balance chart. Essentially, the tool helps workers visualize how much time they are currently spending on tasks versus how fast a business should run, which is measured in Takt time.

The calculation for Takt time is:

Total amount of available work time

------------------------------------------------------------------------

Average # of parts the customer requires

By making it easy to see how time is spent, Yamazumi charts help manufacturers in a few ways. Using one can help you identify where employees are falling behind in their work and where other employees are idle. If you know which workers are experiencing downtime, you can reallocate their efforts to another part of production, thereby improving efficiency. Another benefit is that the chart can help you differentiate between which activities do and do not add value.

Still not clear on what the chart does and how it can benefit factories? Check out the full article in the link below to learn more about Yamazumi charts:

What Is a Yamazumi Chart? – Editorial staff, factorysolutions.com

4. New year, new manufacturing trends

It seems like only yesterday clocks everywhere struck midnight and heralded in a new year. A week has already passed in 2017, however, and it’s important to remember that with a new year comes new manufacturing developments.

Manufacturing around the world will be especially interesting this year. From President-elect Trump’s stance on reshoring manufacturing jobs in America, to Brexit and more, it’s anyone’s guess if global supply chains with suffer or prosper.

Underlying major political changes are a few specific industry advancements are, such as:

- Disruptive 3D printing – Manufacturers might see their traditional business models change as more and more consumers gain access to 3D printers. Rapid prototyping also stands to change the approach manufacturers take toward product development and production.

- Augmented reality (AR), virtual reality (VR) and crowdsourcing – Suppliers are beginning to use advanced technology that will help in real-time to supplement the capabilities of their workers. Similarly, crowdsourcing will allow companies to get quick feedback from customers.

- Shorter product cycles in tech manufacturing – A greater share of consumers have a smartphone than in years past. To stay competitive and keep the attention of smartphone users, manufacturers must innovate and stay ahead of increasingly short product life cycles.

- More green manufacturing – Environmentally conscious consumers mean factories need to adopt renewable energy sources and improve usage efficiency or else risk losing business.

- Artificial intelligence (AI) – The potential of AI to identify defective products and replace them instantaneously is a huge benefit for factories everywhere. Manufacturers can potentially save money and improve product quality by employing AI, but it might eventually become a necessity as industry competition grows fierce.

Not every manufacturer will need or benefit from these changes. But those that respond to them quickly will embrace modern manufacturing and potentially gain a leg up on the rest.

Are you ready for 2017?

To learn more about trends facing manufacturing in 2017, check out the full article in the link below:

Five Manufacturing Trends to Expect in the New Year – Mark Dohnalek, Manufacturing.net

5. Combining additive manufacturing and stretchable electronics

A whole new wave of innovations is possible when we eliminate the constraints posed by typical electronics, like their brittleness and rigidity. Stretchable electronics are helping manufacturers bring down those barriers.

Stretchable electronics use a material called elastomer to give them their flexible and elastic properties.

But the author mentions how stretchable electronics face one pressing challenge: overcoming mismatches. The mismatches are essentially when the small inflexible electronic components are positioned in a way that might break them when the rest of the product is twisted, bent or stretched. To counter this issue, researchers at Missouri S&T are considering using additive manufacturing “to print thin layers of highly conductive materials onto elastomer surfaces.”

But the author mentions how stretchable electronics face one pressing challenge: overcoming mismatches. The mismatches are essentially when the small inflexible electronic components are positioned in a way that might break them when the rest of the product is twisted, bent or stretched. To counter this issue, researchers at Missouri S&T are considering using additive manufacturing “to print thin layers of highly conductive materials onto elastomer surfaces.”

Additive manufacturing might eventually afford manufacturers the customization and precision they need to conform to the requirements of stretchable electronics so that they function properly and don’t break. And with manufacturing technology like this progressing, one day when you’re stretching, a nifty gadget might be stretching with you too.

To learn more about how additive manufacturing can help the future of stretchable electronics, check out the full article in the link below:

Additive Manufacturing: A New Twist for Stretchable Electronics? – Missouri S&T, additivivemanufacturing.com

We’re constantly scanning the web for top manufacturing stories and news. If you’d like to submit an article for consideration for our weekly Best in Manufacturing, send us a message and let us know.