Prior to safety regulations introduced in 1994, federal regulators estimated that 150 children were killed by lighter-related fires every year.

Prior to safety regulations introduced in 1994, federal regulators estimated that 150 children were killed by lighter-related fires every year.

Several years later, the Consumer Product Safety Commission (CPSC) published a study showing a reduction in cigarette-lighter fires caused by children of 58 percent, which prevented 3,300 fires, 100 deaths, 660 injuries and $52.5 million in property damages in 1998 alone. Clearly, product safety for lighters has come a long way.

But there’s still the occasional product recall pointing to a lapse in quality controls. In 2010, Zippo recalled approximately 17,500 lighters because their “excessive flame” posed a hazard to the operator.

It doesn’t matter if you’re importing $500 novelty lighters or $0.50 plastic ones. The hazardous potential of lighters makes QC inspection by professionals all the more important before your product reaches the hands of the end-consumer. Ensuring there are no issues with components and assembly will help protect the people that ultimately use your product and help you avoid a product recall.

Here are the top five on-site tests for lighters to be conducted during product inspection:

1. Switch and flame adjuster check

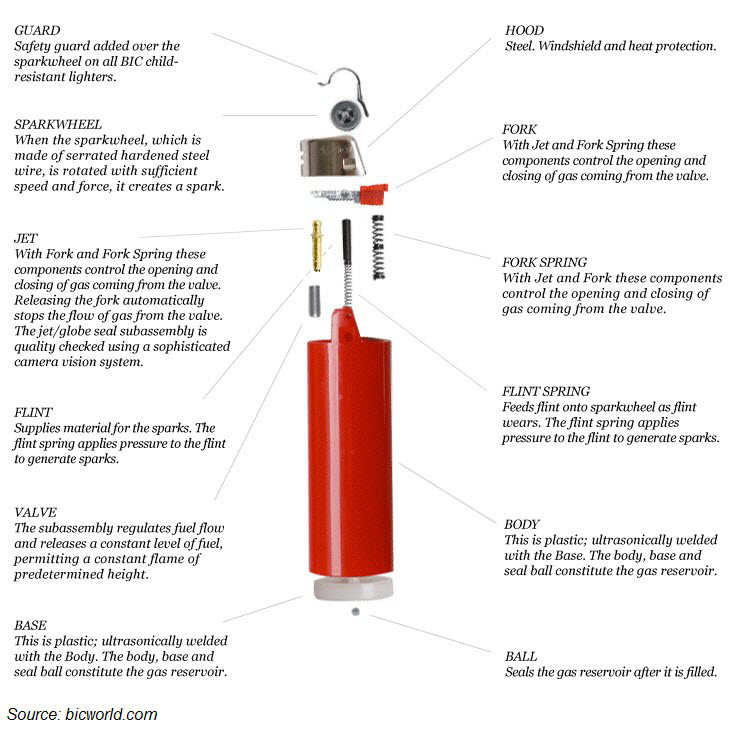

If your lighter has a flame adjuster, this is one of the most basic safety checks to perform during inspection. This test ensures that the fork (a.k.a. switch), spark wheel, guard, adjuster and fork spring are all operating effectively. Failing this basic check indicates one of the most vital parts of the lighter is defective and needs to be checked right away.

The procedure for switch and flame adjuster check

1. Operate the switch system 5 times.

2. Check for proper igniter function and smooth rebounding.

3. Move the flame adjuster to check for proper movement. The lighter fails this test if there is any malfunction during operation.

2. Full function testing for lighters

Function tests for lighters are a staple of most product inspections for this product type. Checking full functionality is especially important during inspection for lighters given how dangerous a lighter can be if it malfunctions. The primary purpose of this test is to verify flame intensity and any flame adjustment options a lighter may have.

The procedure for function checking lighters

1. Start with a lighter full of fuel.

2. Listen to make sure there are no abnormal noises emitted upon pressing the ignition switch.

3. Verify that flame intensity adjusts properly when moving the flame adjuster.

3. Verify that flame intensity adjusts properly when moving the flame adjuster.

4. Check for a steady flame. There should be no obvious bouncing flames.

5. Extinguish the flame and hold the lighter upside down for 5-10 seconds.

6. Return the lighter to an upright position, ignite it and check for a steady flame.

7. Release the ignition switch and verify the flame is extinguished within 2 seconds. If there is a wind shield present, the flame should be completely extinguished within 4 seconds.

3. Continuity burning test

The valve and hood of the lighter are the primary components that are evaluated during this simple on-site test for lighters. A flame that doesn’t burn constantly for 2 minutes often indicates a problem with the valve, which controls fuel flow. This test also examines the durability of the hood and makes sure visual issues do not appear.

The procedure for the continuity burning test for lighters

1. Ignite the lighter and keep a flame burning for 2 minutes.

2. Make sure a steady flame is maintained throughout the test. An inconsistent flame will cause the lighter to fail this test.

4. Aging test for lighters

One of the most common tests for lighters is also important for many other types of products: the aging test. The purpose of the aging test for lighters is to determine a lighter’s longevity under normal conditions. Using aggravated heat conditions to speed up the normal aging process of the lighter, this test is meant to verify that your lighter doesn’t fail or malfunction early.

The procedure to conducting the aging test

1. Place a lighter full of fuel into an aging chamber set to 65°C (149°F).

2. Keep the lighter in the chamber for 4 hours.

3. Ensure that the rate of fuel leakage is less than 15mg/min.

4. The lighter must still function properly after the test is completed. There should be no cracks in the lighter.

5. Switch life test for lighters

Just like with the switch and flame adjuster check and aging test, the switch life test verifies the ability of the lighter’s components to withstand continuous use. The ignition switch is a component that’s more likely to fail early on. Reliability of the switch needs testing to ensure it will last the lighter’s intended span of use.

The procedure for testing switch life

1. Using an auto strike machine, strike and rebound the ignition switch for a full 12,000 cycles.

2. Check that the switch and lighter are still functioning properly.

Conclusion

Pre-shipment inspection is essential for any product, but even more so for a product with enormous destructive potential like a lighter. Even a small lighter defect can cause injury to the operator. In the worst case scenario, a faulty lighter can cause a fire to get out of hand. Understanding these on-site tests for lighters will not just protect your brand, but also the lives of the individuals and families that use your product.