In addition to a list of requirements or specifications, it is always wise to have some master samples of the product you want to inspect available the day of inspection.

In addition to a list of requirements or specifications, it is always wise to have some master samples of the product you want to inspect available the day of inspection.

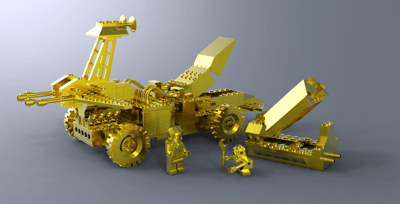

These precious master samples (called also golden or reference samples in the business) will help you compare what has been agreed between you and your supplier with the current production and also to avoid any misunderstandings (which is more than common in China for example). Of course this alone is not enough, as a clear list of specifications and requirements needs to be defined and agreed between the two parties.

The master samples will be used to check if specifications of your products (appearance, size, functionality) are the same than the product you are inspecting! This way, an inspector can easily show your supplier that the color of the shirts or the shape of the mug he’s producing for you is different from what you are expecting!

But where are these samples coming from? Most of the time, your factory itself - in general the factory should also keep master samples to use them for their internal QC.

Getting your samples available for your inspector the inspection day

When you have a partner for your QC in Asia, you will of course have to ship the samples to them; it is important to make sure that these samples will remain in good hands until they are used (during the inspection for example). There are several options for you as a buyer to make them available, yet keep them safe for the day of inspection.

- Best option: It is better, cheaper and faster to send your samples directly to the factory in a sealed package to attention of the inspector.

- If you do not trust your vendor/factory enough, you can send it to your QC company, but note that:

- In this case it is difficult to guarantee that the sample(s) will be sent to the inspector rather than the factory. Some inspectors live alone, far away from their company office, and are on the road nearly every day.

- The booking and the sample shipment have to be done in advance (at least 8 working days) with your QC partner.

Furthermore, It is usually best to send an invoice along with your samples with a $1 price tag so your commercial samples avoid customs problems.