One question nearly every importer will ask at some point is, “Is this the best price I can get?”

One question nearly every importer will ask at some point is, “Is this the best price I can get?”

Like most importers, you’ve probably questioned whether the price quoted by your supplier is “fair” and “reasonable”. You might’ve wondered if you could get a lower price from another supplier. And maybe you’ve had the foresight to balance other important factors against price, such as quality and existing supplier relationships.

Knowing how far to push on price is a challenge even the most experienced importers are bound to face. But luckily, getting the best price from suppliers isn’t as difficult as it might seem. There are ways to do this effectively without compromising on product quality or souring your relationship with your supplier (related: How Experienced Importers Limit Product Defects in 3 Stages [eBook]).

Here are three tips for getting the best price from suppliers:

1. Get quotes from multiple suppliers

Anyone who’s bothered to shop around at multiple stores knows it’s not always wise to accept the first price you see for an item, especially if that item is costly. The same logic applies when it comes to suppliers.

It’s essential to obtain quotes from different suppliers before purchasing an order. You’ll gain a better understanding of the overall market rate for certain items. If you accept the first quote a supplier offers, you might be disappointed later when you discover there were better options available.

Once you’ve contacted at least three suppliers—the more the better—you can begin seriously comparing quotes. Along with obtaining price quotes, it also helps to:

- Ask for a product sample. Although suppliers will typically charge you for producing and sending a sample, this is one of the best ways to really know the product quality before ordering.

- Compare the efficiency and effectiveness of communication between different suppliers. A supplier with a competitive price may not ultimately be worth it if you can’t reliably communicate with them.

Of course, price is important. But a little investigation into suppliers and their product at this stage lends to more informed decision making.

Where to find suppliers

Most importers approach the task of finding suppliers by searching online. Popular websites like Alibaba and Global Sources are search engines used for finding suppliers throughout the world. These kinds of websites typically list suppliers capable of shipping just about any product you’re seeking, whether obscure or commonplace.

Importers that don’t employ their own sourcing staff and would prefer to outsource the task of finding suppliers often turn to a third-party for help. Experienced sourcing companies can save importers time and the headaches of sifting through prospective suppliers. Similarly, some third-party inspection and auditing firms can assist with product sourcing. Most companies can provide you with a list of at least two or three capable suppliers along with pricing estimates and other details for each.

No matter how you choose to find suppliers, what’s most important is that you carefully research multiple suppliers and compare all relevant factors, rather than relying on price as the sole criterion for comparison.

"Source intelligently by using #Alibaba, #globalsources, or a third-party sourcing company."2. Ask suppliers for the BOM and itemized pricing

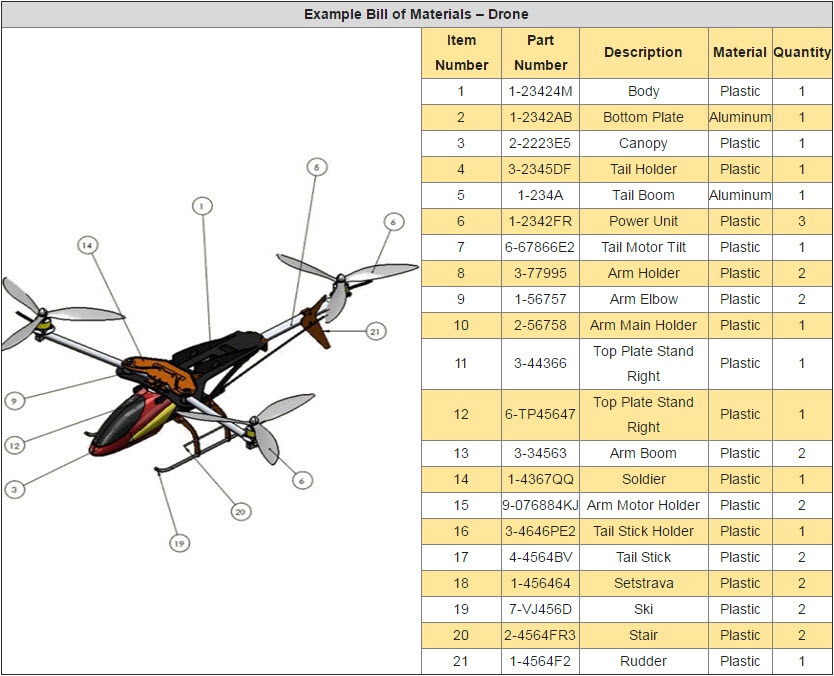

You can learn a lot about how a supplier has priced a product just by looking at its bill of materials, or BOM. The BOM is a list of raw materials, sub-components, and parts (and quantities of each) that are used in manufacturing an end product. This information can reveal why an item is priced a certain way, helping you answer questions, such as:

- What’s the fabric density of the rib material the factory will sew into a sports jersey?

- How many couplings will the factory produce for an order of steel conduits?

- Will the factory use PET or HDPE plastic in injection molding?

Depending on the detail of the BOM, you can learn all of this and more before actually placing an order. Knowing order details like these will help you better understand how the supplier has priced the product. Seeing the BOM also helps you ensure your product specifications are being met. For example, you may find the supplier had planned to use the wrong component and instruct them accordingly.

Consider itemized pricing when choosing suppliers

Another way to know whether you’re getting the best price is by looking at itemized pricing. Like the BOM, itemized pricing typically shows a breakdown of different parts, materials and sub-components included in the finished product. But along with the quantity for each, you’ll also see the unit price.

This type of document generally excludes many other costs involved in manufacturing, such as freight and labor. But many of these other costs are somewhat predictable. You can learn a lot about pricing if you’re familiar with the cost of materials and parts.

It’s important to note that prices for materials and commodities often fluctuate. Suppliers are unlikely to price stainless steel the same from month to month, for example. Keep this in mind when requesting a quote, as pricing may be subject to such changes.

3. Don’t negotiate pricing too low with suppliers

Some importers mistakenly think that getting the best price from suppliers means getting the lowest price possible. But the age-old proverb, “you get what you pay for” is as true here as anywhere else.

Experienced importers know that a lower price often comes with an equal or greater decrease in product quality (related: Preventing Product Defects Starts with Negotiating with Suppliers). This is especially true for suppliers that work on very tight margins. Some suppliers will often try to recover margins lost in negotiations by using cheaper, sub-standard parts and materials, often without your approval. Others may simply refuse your order altogether (related: 3 Reasons a Supplier Might Refuse Your Business).

Experienced importers know that a lower price often comes with an equal or greater decrease in product quality (related: Preventing Product Defects Starts with Negotiating with Suppliers). This is especially true for suppliers that work on very tight margins. Some suppliers will often try to recover margins lost in negotiations by using cheaper, sub-standard parts and materials, often without your approval. Others may simply refuse your order altogether (related: 3 Reasons a Supplier Might Refuse Your Business).

Negotiating very low on price early on can also make your supplier generally less cooperative. This can present a number of challenges, such as:

- Difficulty getting the factory to remedy any quality issues present in the finished goods through product rework;

- Production or shipping delays if factory management makes your order a low priority; and

- Inability to effectively destroy an order of goods at or near the factory, if required (related: Total Product Destruction: The Importer’s Guide [eBook]).

So what’s the best way to negotiate with a supplier?

Be upfront with suppliers and offer a target price

Many importers get anxious when suppliers ask for a “target price” early on in negotiation. They’re often worried they'll end up paying too much if they reveal their expectation too soon. But in fact, it’s usually a good sign when a supplier asks for a target price. It typically shows that they're capable of producing at multiple levels of quality. This is true of most well-established suppliers.

If you’re accustomed to paying $0.20 per unit for ballpoint pens and you tell a prospective supplier directly, you’re likely to arrive at a similar pricing and quality level with them. But if you set your target price lower—at $0.10 or $0.15, for example—you’ll probably find that the supplier will agree. But that quality will be lower than what you’ve seen in the past, when paying the higher price.

It’s generally best to be upfront and open with prospective suppliers about how much you expect to pay for a product. Make your expectations for quality clear to them as well. They may not be able to meet your price and quality level immediately. But perhaps there’s a way by substituting different parts or materials or increasing the order volume. It’s difficult to be sure without an open discussion.

If you want added assurance of product quality before finalizing an order with a supplier, ask them for a product sample (related: 3 Must-Do Procedures for Handling Golden Samples for Manufacturing). It may also be wise to carry out lab testing, particularly to verify the quality of materials or to check product performance against a benchmark.

"Aggressive #supplier #negotiations might hurt quality more than it helps your bottom line."Conclusion

Upon opening a shipment of product, you’ll experience one of two outcomes: you’re either satisfied or not. You might receive goods that you’d rather throw away than sell to your customers. This disappointment is likely to overshadow any satisfaction you felt by getting a super low price from your supplier.

Getting truly the best price means looking at details from multiple perspectives and avoiding the temptation to push for the lowest price possible. Above all, be open and direct with any suppliers with whom you’re seriously considering working. Doing so not only helps you get the best price and product quality, it also helps ensure your relationship with a new supplier starts off on the right foot.

And if you’d like to learn about how to negotiate with Chinese factories specifically, don’t forget to check out 5 Tips for Negotiating with Chinese Factories!

And don't forget to check out the manufacturing podcast episode that covers this topic!

What strategies do you employ in negotiating on price with factories? Share your tips and stories in the comment section below!