Best in Manufacturing – August 13, 2017

Each Sunday, we publish a list of top articles and other content related to manufacturing in areas like quality control, product development, supply chain management, sourcing, auditing and law.

1. Lessons from the failure of the fidget cube

What the heck is a fidget cube? Basically, it’s a toy for people that like to fidget. The toy is outfitted with a mini ball, buttons and other apparatuses that make fidgeting a little more interesting.  Antsy Labs, the creator of the toy, originally debuted the idea on Kickstarter to much fanfare and to date the campaign has raised over $6 million.

Antsy Labs, the creator of the toy, originally debuted the idea on Kickstarter to much fanfare and to date the campaign has raised over $6 million.

Raising so much money for a Kickstarter campaign centered on a small piece of plastic is impressive, at least to me. In fact, the project is the tenth highest funded on the site. Yet despite this funding success, the fidget cube ran into quality issues. An official statement from Antsy Labs long ago reads:

We need to let you know that we discovered an issue that we had to make a tough call on… We had to make the difficult decision to briefly pause shipping in the name of quality

So then the real question is… what happened?

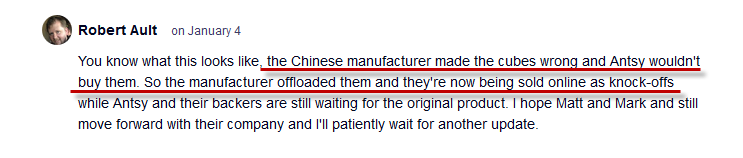

Some people, like one man in the Kickstarter campaign’s comments section, speculate that Antsy Labs’ supplier made the cubes wrong and they wouldn’t buy the sub-par cubes.

Aside from this speculation, the author of this featured article believes Antsy Labs did not have proper risk management in place. Essentially, the author states that Antsy Labs didn’t have any plans in place to handle unforeseen circumstances. And while it’s hard to prepare for the unexpected, the author offers a few sample questions that could’ve helped Antsy Labs avoid setbacks:

Aside from this speculation, the author of this featured article believes Antsy Labs did not have proper risk management in place. Essentially, the author states that Antsy Labs didn’t have any plans in place to handle unforeseen circumstances. And while it’s hard to prepare for the unexpected, the author offers a few sample questions that could’ve helped Antsy Labs avoid setbacks:

- “How will you deal with knockoffs and copycats?”

- “How involved with the manufacturer should you be along the way, so mistakes aren’t found too late in the process?”

- And more!

The case of the fidget cube is a lesson in the importance of timing and execution. If Antsy Labs had done a better job of bringing their product to market with the chance that they were given, they might be millionaires right now. Instead, the fidget cube now lives in the shadow of the more popular fidget spinner.

Bringing a new product to market isn’t easy, but this story can hopefully help you succeed with your own ideas. And as a matter of fact, I talked about this story in my presentation to Hardware Massive on July 19, 2017. The presentation is entitled “QC Horror Stories and How Not to Become One” and covers a number of ways to avoid quality problems.

To learn more about the fidget cube and the lessons the story has for your business, click the presentation title above to view the YouTube video of my talk or check out the full article about the topic in the link below:

The Curious Case of the Fidget Cube – Christopher Martin, Quality Digest

2. Understanding exactly how 3D printing works

3D printing is a modern marvel. The technology creates an object by printing it layer upon painstaking layer. 3D printing is also known as additive manufacturing, which stands in contrast to subtractive manufacturing, whereby part(s) of an object are removed until the final desired form is achieved.

But sometimes, in the process of admiring additive technology, we might overlook the exact science behind how it works. Thankfully, the YouTuber “engineerguy” has an in-depth explanation of how 3D printing works. You can check out the video below:

I don’t understand much engineering and chemistry and how they’re used in additive manufacturing. Yet this explanation of how 3D printing turns an item from resin to a solid object was both fascinating and easy to follow. You can watch the video above or you can read this explanation of some of the concepts discussed in the video by checking out this post by Popular Mechanics:

An Extremely In-Depth Demo of How 3D Printing Works – David Grossman, Popular Mechanics

3. The Chinese “Greater Bay Area”

Beijing, Shanghai and Hong Kong. These are the three cities that typically take the spotlight when someone thinks about China. But adjacent to the border with Hong Kong is Shenzhen and a handful of other cities also worthy of recognition.

These cities create a formidable region capable of international trade, finance, innovation and manufacturing. They’re all part of the Pearl River Delta and are at the heart of a plan by Premier Le Keqiang to create a “Greater Bay Area” that is culturally and economically intertwined.

Shenzhen, for example, is home to around 12 million people and major Chinese companies like drone maker DJI, smartphone producer Huawei and Tencent, the creator of WeChat. Just to the north, Dongguan serves the manufacturing needs of countless international clients. And Hong Kong, to the south of Shenzhen, is undoubtedly a financial and legal hub known the world over.

Speaking to the advantages of Shenzhen, in particular, one entrepreneur had this to say:

Manufacturing requires a lot of back and forth and spur-of-the-moment problem solving. Having people on the ground in Shenzhen gives us a real advantage not just in terms of cost, but more importantly in speed.

This advantage is compounded by the fact that many suppliers, innovators and business people are so close together. If you’ve got a supplier in Zhuhai, a designer in Foshan and a logistics company in in Guangzhou, you’ll more likely have an easier time coordinating with them and resolving problems due to their close proximity.

Do you feel like the Pearl River Delta is the right place to be for manufacturing, business and technology? Let us know in the comments below.

To learn more about the Pearl River Delta and the new “Greater Bay Area”, check out the full article in the link below:

Can China’s ‘Greater Bay Area’ Match Its New York and San Francisco Counterparts? Much will Depend on Beijing – Raymond Cheng, South China Morning Post

4. Chinese factory towns changing from internal migration reforms

Hukou (户口,hùkǒu): what is it? It’s a household registration system that acts as a gate to internal migration in China. The system connects social benefits, such as healthcare and education, to one’s birthplace.

For migrant workers, the hukou system can be a challenge at times. Without hukou registration in the area where a worker has employment, it’s extremely expensive to raise a family there because migrants aren’t provided the same social benefits as locals. And this creates another problem: workers might feel more inclined to leave the area to return to their family, creating an employment problem for the businesses that hired them.

But a reform in 2016 aims to give 100 million migrant workers residence permits. Essentially, more workers will gain access to public services, which can solve issues like children being left behind by their parents as they travel to other locations to work and support the family.

The benefit of hukou reform for importers and manufacturers is that more migrant laborers can move their families to where they work, which might decrease turnover rates. Rather than intensify the massive shift of people that takes place every year around Chinese New Year, hukou reform could relieve the problem and get workers back to production lines sooner. And just as important, workers will likely be happier without having to travel as far as to see their loved ones.

Curious about hukou reform? Check out the full article in the link below:

How Hukou Reform Is Changing the Makeup of Chinese Factory Towns – Eric Fish, Asia Society

5. The next steps for Cambodian manufacturing

Earlier this year I wrote about Cambodia’s increasing manufacturing appeal (see #4). And while the country certainly has some advantages, like an abundance of cheap labor, this featured article points out a few issues.

Labor productivity, for example, was 30 percent higher in 2015 than in 2003, but it wasn’t at the levels of its neighbors like Indonesia, the Philippines and Thailand. Adding to this problem, infrastructure remains at times unreliable and not conducive to business.  Factories sometimes suffer power outages. Logistics in the country aren’t reliable and efficient enough, leading to the highest export costs in the ASEAN region.

Factories sometimes suffer power outages. Logistics in the country aren’t reliable and efficient enough, leading to the highest export costs in the ASEAN region.

Ken Loo, Secretary General of the Garment Manufacturers Association of Cambodia, is blunt: “As we stand, where we are today, we’re not competitive”. So how can Cambodia become more of a contender in the international manufacturing arena?

In 2015, a great deal of Cambodia’s seven-percent GDP growth was tied up in the apparel industry – two percentage points, to be exact. This reliance on one industry is dangerous, and the country needs to diversify in order to become a stronger manufacturing country. The Cambodian government plans to reduce garments to 50 percent of all exports by 2025.

Aside from diversifying what’s exported, the country’s manufacturing sector also needs to invest more in modern technology and train workers to use it. Otherwise, Cambodia will slowly lose its appeal as a country for production.

To learn more about Cambodian manufacturing, check out the article in the link below:

Cambodia manufacturing on the line – Paul Millar, Southeast Asia Globe

We’re constantly scanning the web for top manufacturing stories and news. If you’d like to submit an article for consideration for our weekly Best in Manufacturing, send us a message and let us know.