Regardless of which QC company you use, product inspection reports will generally have three different result categories – pass, pending or fail. While pass and fail are self-explanatory, the pending result begs the question, what exactly is “pending”?

Many importers make the mistake of thinking inspection reports directly indicate whether your supplier whether an order should ship (related: 5 Misconceptions of QC Inspection in China [eBook]). But only you as an importer can judge if an order is acceptable. This is particularly true in the case of pending results.

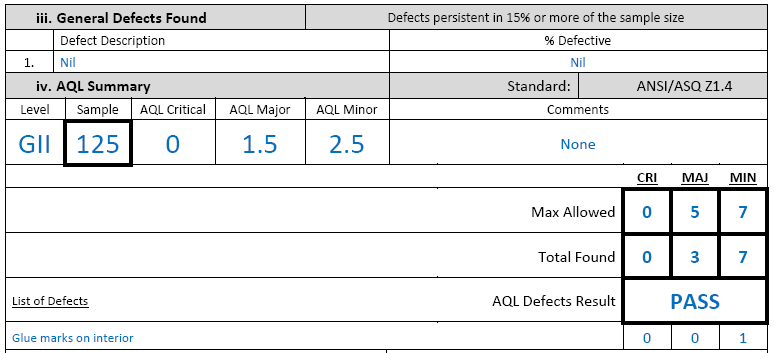

Generally, an inspection which is using an acceptable quality level (AQL) sampling method for inspection will have two results. First you have the result of AQL inspection, in which you’ll find any visual and workmanship defects based on the sample size inspected. Second is the overall result of the inspection.

Firstly, I would like to point out that an overall pending result can only occur when the AQL result is a “pass”. If the AQL result is “fail”, then the overall result will automatically be fail, with no other possible result. However, just because the AQL result is pass doesn’t necessarily mean that the overall result of the inspection will be a pass. That’s where pending comes into play.

For example, let’s say you place an order for 2,000 widgets and your inspector checks an AQL sample size of 125 pieces. If the defects found are within tolerance the AQL result will be pass. But that doesn’t mean the end result is a pass. It’s still possible that the overall result will be pending or fail.

What is meant by a “pending” inspection result?

The pending result following a product inspection is directly related to remarks in the report which are brought to your attention as possible defects. It is essentially an issue of points of variance to the provided information about which the inspection company is not sure. Therefore, it is left up to you as the buyer and the client to decide how those points should be considered.

Some of the types of findings which are generally reported as pending are as follows:

- Variances in packaging requirements

- Dimensional discrepancies

- General non-crucial points of difference between production and the provided specifications

These are normally findings that many professional inspectors may not consider to be serious enough to warrant failing the inspection but important enough to have the buyer review before accepting the result as a pass.

How do you address a pending inspection result?

It's always the importer's responsibility to address pending inspection results. Remember product inspectors cannot withhold or authorize a shipment, nor work with them directly to fix issues found during inspection (related: Why Product Inspection Companies Can't Compel Your Chinese Suppliers).

Some clients are happy with pending results for product inspection, as they like to then take the opportunity to advise the factory on whether the goods are acceptable or not. If the factory were to see a passing result, it is difficult for the client to then advise on the specific issues they want to have reworked.

they like to then take the opportunity to advise the factory on whether the goods are acceptable or not. If the factory were to see a passing result, it is difficult for the client to then advise on the specific issues they want to have reworked.

Many clients, on the other hand, do not like the pending result and simply want a straightforward pass or fail result. So how can you get to pass/fail and stop having pending results?

The answer is simple. Give feedback on the pending issues to the inspection company and the factory. You need to establish how those specific issues are to be considered going forward. If they are not important, they can be completely left out of future reports or you can simply have them included as a “note”, which will not affect the overall result of the product inspection.

Conclusion

It is important to know how to handle receiving a pending result in an inspection report as they are not altogether uncommon. A recommended course of action would be to have the inspection company keep a record of issues which are not to be considered pending going forward.

Afterward, your inspectors will be able to report a more accurate inspection result. Without feedback, it is very difficult for the inspection company to advise if something is a pass or fail as there may be serious issues that need to be brought to the buyer’s attention.

Click the link below to download our eBook and learn more about what inspection results mean for your shipments!