Have you ever sent an approved sample to a factory for your QC inspector to have during inspection? Has your supplier ever sent you a sample of defective product following a product inspection? How were you able to be sure that the right sample got to the right person?

Have you ever sent an approved sample to a factory for your QC inspector to have during inspection? Has your supplier ever sent you a sample of defective product following a product inspection? How were you able to be sure that the right sample got to the right person?

In previous articles, we’ve talked about the importance of golden samples during the production and inspection process to prevent product defects (related: How Experienced Importers Limit Product Defects in 3 Stages). Recently, we mentioned how important it is to seal samples of defective product at the factory, in case the buyer wants the factory to review the item first-hand.

In this article, we’ll walk you through the simple process of sealing samples to prevent tampering and when it matters.

Why Seal a Golden Sample?

The main reason for sealing a sample would be to avoid any kind of tampering by anyone besides the recipient. A common type of tampering that occurs is when a buyer sends a sample to the supplier to be used for comparison in an upcoming product inspection. It is not unheard of for a factory to open an unsealed sample and replace that with one from their production line. Why, you may ask? Replacing a sample allows them to alter the standard used by the QC inspector in favor of a “passing” inspection result.

If you’re sending a sample to the factory directly, rather than to your QC company, you’ll want to take precautions to prevent the factory from switching out the sample with something  substandard. You can accomplish this by properly sealing the approved sample before sending it (related: 3 Must-Do Procedures for Handling Golden Samples for Manufacturing).

substandard. You can accomplish this by properly sealing the approved sample before sending it (related: 3 Must-Do Procedures for Handling Golden Samples for Manufacturing).

Why Seal Defect Samples During Product Inspection?

Another way buyers get duped is when they don’t require their samples to be sealed specifically by their QC inspector when requesting a sample of defective product. When an inspection report is not enough to gauge the severity of a defect with your product, it is recommended that you ask your inspection company to seal a defect sample on-site. Without a properly sealed sample from your inspector, a factory can easily pick and choose from the lot in order to send the buyer the least defective product. This way, the buyer might underestimate a defect and forgo reworking an order they might otherwise have wanted reworked.

For that reason, if you need a sample sent to a lab – or to yourself – verify that it has been properly sealed by your QC partner during product inspection. Though buyers want to believe that tampering won’t happen, sealing a sample is the best way to minimize the risk of misrepresentation.

InTouch Sample Sealing Method

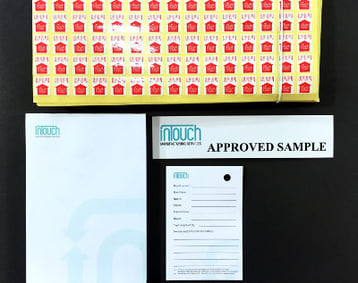

Considering the potential for receiving compromised samples, InTouch has developed a simple, cost and time-effective way to avoid any tampering with samples. The recommended process for sealing product samples is as follows:

- All samples are labeled with an InTouch sample tag, on which is written information related to item details, the buyer, the supplier, the person tagging the item and other notes.

- The samples are placed in a carton and the carton is sealed with packing tape.

- InTouch pad paper is placed over at least 2 edges on each side of the carton and taped down, leaving some space for stamping.

- An InTouch stamp is applied to the carton so it covers both the pad paper and the carton under one stamp.

- Finally, the paper is covered with tape so no one can remove the stamp or the paper.

Conclusion

This simple yet key preventative measure is often overlooked by many new buyers. Sealing samples ultimately protects buyers from innumerable headaches and tons of unwanted costs, which eventually come about when they receive a substandard order. Maybe you’re sending a golden sample to your supplier for your inspector to have on-hand during inspection. Or maybe your inspector is sending a sample of defective product to you for reference. Regardless of the circumstances, make sure that product samples are sealed properly to prevent tampering!

Do you have any tips for establishing and handling golden samples for manufacturing? Share your thoughts below!