High performance and durable machine parts are important for industries that are dependent on machinery. China is becoming the premier source of cheap high quality machine parts. These inexpensive parts allow users to operate in much lower costs; giving them an edge over the competition.

InTouch is the leading machine parts inspection and quality control services provider in China and has helped a wide range of machine part brands, importers and retailers to perform high-level inspections and on-site testing.

Some of the international standards which InTouch employs in developing machine parts inspection protocols include:

ASME B5.54

The American Society of Mechanical Engineers standards provide the test method for evaluating the performance of the machines used in producing custom-built machine parts. ASME B5.54 covers the test procedures in evaluating Computer Numerically Controlled (CNC) Machine Centers.

ASME B5.57

The American Society of Mechanical Engineers are significant in establishing that a potential supplier possesses the necessary equipment capable of producing machine parts that are within the required limits and specifications. ASME B5.57 covers the test procedures for the Computer Numerically Controlled (CNC) Lathes and Turning Centers.

ASME Y14.5 - B89.7.3.1 - B4.2 - B46.1

Some machine parts are so unique that they can only be obtained if they are custom built. CAD is a popular method of communicating the specifications and limits for these kinds of machine parts to their manufacturers. These standards from the American Society of Mechanical Engineers provide the acceptable practice in designing and the methods in interpreting the drawings and models for machine parts.

- ASME Y14.5 covers the guidelines for geometric dimensioning and tolerances for machine parts models and designs.

- AMSE B89.7.3.1 covers the guidelines for establishing conformance or non-conformance of the manufactured machine parts in reference to the agreed specifications. AMSE B89.7.3.1 is very essential in settling disputes between buyers and suppliers regarding conformance issues.

- ASME B41.2 covers the acceptable limits and fits for manufactured machine parts.

- ASME B46.1 covers the guidelines in specifying the surface texture of machine parts during the design process. ASME B46.1 also covers the inspection and quality control methods in determining whether the agreed specifications on surface texture have been complied with.

ASME B29.8

Using high quality leaf chains, clevises, and sheaves, machine parts that transmit mechanical inertia, ensure that machines are working at optimum performance. This standard from the American Society of Mechanical Engineers covers the specific guidelines in manufacturing, designing, and testing leaf chains, clevises, and sheaves.

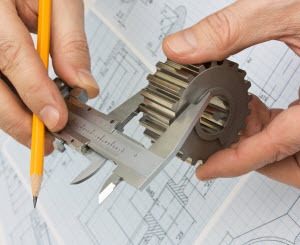

AGMA 913, ANSI/AGMA 2000, ANSI/AGMA 1103, ANSI/AGMA 6011 and ANSI/AGMA 6002

These standards developed by the American Gear Manufacturers Association cover the most common types of gears used today, the spur and the helical gears.

- AGMA 913 covers the guidelines in specifying the geometric characteristics of spur and helical gears.

- ANSI/AGMA 2000 covers the inspection and classification guidelines for spur and helical gears; including methods for determining gear tooth tolerance.

- ANSI/AGMA 1103 specifies the gear tooth proportions for these types of gears.

- ANSI/AGMA 6011 covers the requirements for helical gears intended for high speed applications.

- ANSI/AGMA 6002 covers the design requirements for spur and helical gears for vehicles.

AGMA 909, AGMA 920 and ANSI/AGMA 1106

Plastic gears are useful in applications that require gears to be lightweight, non-corrosive, and inexpensive.

- AGMA 909 provides the guidelines for designing and manufacturing molded plastic gears. It recommends a standard method for specifying gear features and for determining the necessary manufacturing and inspection considerations.

- AGMA 920 covers the materials used in the production of plastic gears.AGMA 920 provides the necessary recommendations and literature for gear materials, operating environments, manufacturing, inspection and testing, and plastic gear properties.

- ANSI/AGMA 1106 covers the specific recommendations for plastic gear tooth proportions and their recommended applications.

ASME B40.200

Thermometers and pressure gauges are indispensable in monitoring that machines are working at safe temperature and pressure levels. Exceeding these limits may cause poor performance and may even risk the safety of the workers near the equipment. ASME B40.200 covers the guidelines in manufacturing and testing thermometers for machines.

[sidebar name="case studies"]