Destroying your products to save your import business sounds pretty counterintuitive, doesn’t it?

Destroying your products to save your import business sounds pretty counterintuitive, doesn’t it?

But failing to properly destroy and dispose of defective products could truly be the downfall of your business if you’re not careful. Defective products misrepresent the brand you’ve worked so hard to grow. They can lead to bad reviews from customers on Amazon, other ecommerce sites and elsewhere. And they can lead to product returns and even product recalls in the most serious cases.

Many importers conduct product inspection before shipment to catch any defective products before they can reach their customers. And if possible, they may ask their supplier to rectify the problem through product rework or other means.

But sometimes quality problems can’t easily be fixed and are serious enough that your import business would be severely damaged if the goods reached customers. In times like these total product destruction services may be the only way to save your business.

Let’s explore three ways that destroying your defective or rejected products might help you avoid disaster.

1. Avoid product liability issues for dangerously defective products

While defective products can hurt your brand, the most serious consequence of letting defective products slip onto the market is the danger they can pose to consumers.

One infamous example is the Model 700 rifle sold by Remington, an American firearms company. The rifle had a defect causing it to fire without consumers pulling the trigger. The defective rifles are thought to have caused at least two dozen fatalities and more than 100 serious injuries, leading to a class action lawsuit in 2013. Although they denied allegations of negligence in court, Remington later agreed to replace the trigger on 7.85 million rifles free of charge.

Guns might seem naturally more vulnerable to safety liability issues. But other seemingly harmless products can also cause tragedies. Just last year, a faulty connector in a whipped cream canister caused an explosion that resulted in the death of a French fitness model. Regardless of your product type, never underestimate the potential hazards a defective product can pose to consumers.

In cases similar to the above examples, manufacturers are held liable for both design defects and manufacturing defects. According to U.S. product liability laws:

- A design defect occurs when there’s an inherent flaw or error in a product’s design that renders it unreasonably dangerous. The product was manufactured and used as intended.

- A manufacturing defect occurs when a product is improperly manufactured and departs from its intended design in a way that poses a danger to consumers.

- The “strict liability” doctrine allows consumers injured by a defective product to recover compensation from the manufacturer or seller, without proof of negligence.

Due to the strict liability doctrine, consumers don’t have to prove you were negligent or careless in causing the defect. They just have to prove they were harmed from it.

Product liability suits often result in manufacturers having to compensate the injured party for hospital bills, lost wages, lost future income due to lasting disabilities and costs of replacement goods. Considering all the costs of liability, protecting consumers from hazardous defects has to be a concern when protecting your brand.

How destroying hazardous products protects consumers from harm and brands from liability

Destroying any products with hazardous defects the factory can’t correct with rework will keep them off the market. Without properly disposing of the goods, your supplier could sell the products under your branding through unauthorized channels known as the grey market. And despite your intent to protect consumers, your brand will be liable for any damages if consumers who purchase your product are injured.

Product destruction helps you proactively address potential liability to avoid the expensive and time-consuming lawsuits that could irreparably damage your brand. So if a defect that can’t easily be corrected at the factory has made your product dangerous, consider destroying the affected goods to protect consumers and your brand.

2. Keep substandard goods that could damage your brand off the market

Legal liability and consumer safety aren’t the only risks to a brand facing product defects. Less serious quality issues can also hurt your brand’s reputation. And when consumer perceptions fall, a similar drop in sales usually follows.

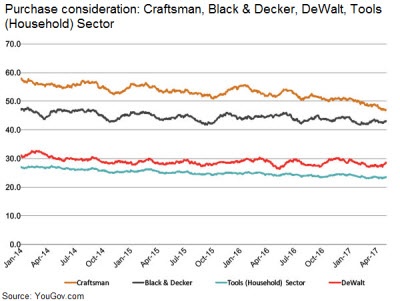

America’s household hand tool industry is one example of where substandard goods have led to a decline in brand prestige and consumer perception. Craftsman, in particular, has suffered such a decline in recent decades. What was once heralded as “America’s Most Trusted Brand” is now the subject of critical user feedback on popular forums like Reddit and The Garage Journal.

Complaints from Craftsman users generally focus on the quality of materials and function of the product, rather than on safety. In quality control terms, defects related to these quality issues would be classified as major defects (related: 3 Types of Quality Defects in Different Products). While major defects aren’t hazardous to users, they typically cause the product to fall short of customer expectations, which often results in:

- Negative reviews of the product

- Mass product returns

- Reduced sales and profits

Maintaining a certain quality expectation among your customers by limiting substandard goods is vital to the success of your business. But when is it necessary to destroy substandard goods?

When destroying substandard goods is most effective

When defects are found in your products and the goods can be reworked to correct them, rework is often the best plan of action. But sometimes rework is not feasible and issues appear in a high quantity of the goods (related: 4 Post-Production Defect Management Strategies for Substandard Goods). In these cases, product destruction may be your best option for protecting your brand’s reputation by keeping substandard goods from reaching customers.

Substandard goods with major defects are perhaps even more susceptible to being resold on the grey market than those with more serious issues because there’s little liability risk attached to them for your supplier. Product destruction services help ensure any products that don’t meet your customers’ expectations aren’t sold to customers.

3. Protect intellectual property and keep rejected products out of competitors' hands

Sometimes it’s necessary to destroy products to keep intellectual property out of the hands of competing manufacturers.

Manufacturers might be able to produce your product at a faster rate than you can, especially if they have lower quality standards than you. And a dangerous, but often overlooked, possibility is manufacturers reselling your rejected products or prototypes on the grey market before you even get your product to market.

Antsy Labs, creators of the Fidget Cube, learned this lesson the hard way. They were poised for instant success as 154,926 backers funded their product on Kickstarter, ultimately raising almost $6.5 million to bring the product to fruition.

But as Antsy Labs was approaching their first shipment, they found product defects that rendered one of the parts of the cube unusable. They chose to hold the order for rework and replacement so they could later release the product with the quality they had envisioned from the beginning.

Soon after the delay announcement, knock-offs of the fidget cubes flooded the market as manufacturers grabbed the golden opportunity to meet demand for the product with their own off-brand versions. This eventually resulted in Antsy Labs, the original creators, hitting the market far later than their competitors. They likely lost hundreds of thousands, if not millions, of dollars in sales.

A defective product might seem useless to you if you can’t sell it to your customers. But your supplier might see it as a valuable commodity they can sell to your competitors or as wholesale products on the grey market. Total product destruction can help protect your intellectual property if you’re left with unsellable defective products that can’t be reworked.

How can you be sure product destruction services are effective and complete?

More than a year after they first launched their product, Antsy Labs is still in the midst of litigating and enforcing their intellectual property rights. Antsy Labs maintains in a project update published last month that their suppliers had no role in leaking their intellectual property to competing factories. But it’s a risk you should consider, no matter how strong you think your relationship is with your supplier.

You’re more at risk for your rejected products hitting the grey market if you:

- Don’t conduct product destruction at all, or

- Don’t hire a third party to oversee the product destruction process or oversee it yourself

Product disposal often comes at an added cost for suppliers. And rather than take the loss and move on, suppliers often want to make a profit on rejected products by selling to another buyer if they can. And in the age of ecommerce, this is easier than ever for factories to do. With little oversight, factories can market your rejected products with your branding and even your copyrighted photos with little fear of retribution.

Hiring a trusted third-party agent to oversee product destruction will ensure that your factory doesn’t sell your rejected products “out the back door”, or without you knowing. With an agent on site, you can receive full assurance through photos and a report showing that your supplier destroyed 100 percent of your rejected products (related: Which Product Destruction Method is Right for Your Rejected Products?).

Conclusion

Although it sounds counter-intuitive, product destruction can be an effective method to protect your bottom line. Product destruction prevents your hazardous defective products from causing harm to end consumers and saves you from litigation.

It also ensures that the product carrying your brand name represents the quality level you’ve paid for and your customers have come to expect. Otherwise, factories can take your rejected products to market where they damage to your brand’s reputation.

Total product destruction might be your last resort, but sometimes it’s necessary for eliminating risk and keeping your business afloat. If you do need to conduct product destruction, remember to ensure the destruction process is sufficiently monitored to guarantee products are 100 percent destroyed. If you leave product destruction entirely to your supplier, you may find they only destroy some of the goods, or none at all.

What tips do you have for ensuring product quality issues don’t hurt your importing business? Share your advice in the comment section below!