Best in Manufacturing – August 20, 2017

Each Sunday, we publish a list of top articles and other content related to manufacturing in areas like quality control, product development, supply chain management, sourcing, auditing and law.

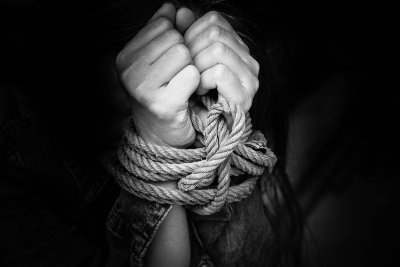

1. Is there slavery in your supply chain?

I enjoy an occasional piece of chocolate. Not every day, but once in a while, it hits the spot. But what can make this confection taste a little less sweet is discovering that child slavery exists in its supply chain.

Slavery doesn’t just exist in the supply chain for chocolate. It also exists in the seafood industry, for instance, in the form of slave laborers peeling shrimp. And slavery might exist in many other industries – including your own – without you even knowing.

On the surface, a first-tier supplier might seem like an ethical company that follows all the rules. At this level, it might seem impossible that slavery exists in your supply chain. Yet second and third-tier suppliers might not be so compliant. Even though you might not directly work with these suppliers further on down your supply chain, they’re still part of it, and you could ultimately be held accountable for their social compliance violations and ethical lapses.

As the author of this article points out, legislation like the Modern Slavery Act 2015 in the United Kingdom and the California Transparency in Supply Chains Act in the United States is an attempt at holding companies accountable for their supply chains. Regular audits at multiple points in your supply chain and an awareness of what’s really happening “on the ground” can ensure these laws, and those in your respective country, are dutifully followed.

What else can you do about modern day slavery in supply chains? Read this featured article to find out:

Is Your Supply Chain at Risk for Modern Slavery Violations? – Ryan Day, Quality Digest

2. Artificial intelligence and better quality control

Place yourself in the shoes of a worker in China that has to check thousands of plastic circuit boards (PCBs) every single day. You’re doing the same thing over and over again. Sometimes, the PCBs aren’t exactly the same. Sometimes, too, you get tired and look at one PCB with a little less scrutiny than others.

Herein lies the problem with humans performing monotonous quality control (QC) tasks: there’s room for error. After hours of QC on PCBs, you might gradually perform the job with less accuracy, which can lead to defective goods and higher costs for the supplier.

But change is coming to QC in factories. In the case of China, the government is spending large sums of money as part of its Made in China 2025 initiative to improve the country’s manufacturing industry. Part of that improvement will likely affect QC due to the government’s interest in factories that include advanced manufacturing (like artificial intelligence [AI]) in their operations.

One improvement this featured article mentions is a form of AI called a convolutional neural network (CNN). On an assembly line, this remarkable technology is capable of learning how to distinguish good parts from bad parts “with incredible speed”. And while some QC workers will be lost as AI is deployed, with repetitive tasks eliminated, that will free employees up for more important, value-adding tasks.

Curious about AI in quality control? Check out the featured article that covers this topic by following the link below:

Using Artificial Intelligence to Improve Quality Control – Kevin Yang, William Hang and Zihua Liu, Quality Mag

3. Overcoming the unique issues that come with Chinese manufacturing

I think you’d be hard pressed to find anyone that’s alright with orders getting delayed.  Especially when sourcing from abroad, a production delay of even one day might disrupt all your other plans and set you back by a week or more.

Especially when sourcing from abroad, a production delay of even one day might disrupt all your other plans and set you back by a week or more.

For instance, if you manufacture in China, you might be aware that sometimes there are some specific issues that affect production there. These issues could ultimately put you in an uncomfortable position with your clients who aren’t buying the excuse of “XYZ happened in China and the order was delayed”.

Knowing about these issues in advance, however, can help you and your supplier prepare for them and create a plan B. Regarding Chinese production challenges, the author of this featured article mentions:

- Sudden rule changes and factory closures

Local governments will sometimes shut down factories for polluting, for example, or after it’s discovered they don’t comply with recently passed laws. One of my personal favorite examples of this in action is this snippet from China Law Blog:

Are you aware that China Customs has issued a new edict requiring all 加工贸易 companies to provide a renewed 商务証 and that in order to get this they (or some other agency) has specified that we must have current land title, workplace safety certificate, environmental certificate and fire safety certificate? If not, you will be hearing more soon. Most of the factories in China cannot come up with all of these because they are illegal. The s**t has really hit the fan here in ________ over this and the edict is said to apply to the whole of China.

This holiday is one of the biggest migrations on the planet. Around 3 billion trips take place during CNY and that certainly includes the travel that factory workers take. Production literally grinds to a halt for thousands of factories as workers return to their hometowns to see their families. CNY is a holiday not to be underestimated.

- Rainy season

- Excessive demand for energy

You can find out more information about the bottom two issues by checking out the full article in the link below:

Managing China’s Unique Production Challenges – Renaud Anjoran, qualityinspection.org

4. Labor costs in China compared to Eastern Europe

China’s labor costs are often compared to those of its neighbors in Southeast Asia, like Vietnam and Cambodia. But this featured article makes another, less common comparison between wages in China’s biggest cities and the countries of Eastern Europe.

Shanghai, China’s most expensive city, now has median monthly wages of about $1,135. In comparison:

- Croatia's median net monthly salary is lower than Shanghai’s at $887

- Hungary's gross average monthly salary is most comparable at $1,139

- Czech Republic’s richest city, Prague, has a higher median monthly salary of around $1,400

Median wages are likely much higher than you would end up paying as labor costs for assembly line factory workers. Shanghai’s monthly minimum wage, the common rate for low skilled workers, is still only $338. And monthly minimum wages in Central and Western China can be as low as $150. But the rise in wages reflects an overall rise in living standards and expectations that will likely trickle down throughout China’s population over time.

If you’re considering hiring full-time product inspectors and support staff, you’ll likely need to pay them an annual salary that reflects living standards. But labor costs are also only one factor to consider when manufacturing abroad, as China might still provide better supply chain connections than some Western countries.

If you’d like to take a closer look at the wage comparisons between China and Eastern Europe, follow the link below:

China Wage Levels Equal to or Surpass Parts of Europe – Kenneth Rapoza, Forbes

5. Vietnam’s advantage as a neighbor to China’s supply chains

As China’s wages rise and manufacturing shifts towards more value-added activity, many importers have started to consider production in other countries in Asia (related: Top 4 Asian Countries for Manufacturing Garments). Due to its ease of doing business and well-educated workforce, Vietnam is the country most often heralded as the “New China”.

One of Vietnam’s biggest advantages is its proximity to China. Given China’s numerous factories and experienced workforce, China will likely remain a key part of manufacturing supply chains for many years to come. The author of this featured article points out,

One of Vietnam’s biggest advantages is its proximity to China. Given China’s numerous factories and experienced workforce, China will likely remain a key part of manufacturing supply chains for many years to come. The author of this featured article points out,

Assembly can never move that far away from China without compromising on supply chain responsiveness.

This is good news for Vietnam, the closest neighbor of China’s manufacturing heartland in the southern Pearl River Delta. Particularly for electronic products, proximity to China is key as China starts to manufacture more critical components. If product components need to be sourced from far-flung locations, you’ll likely face longer lead times and be less flexible to shifts in customer demands. And transportation and logistics costs can also add up.

But in order to deliver on supply chain responsiveness, Vietnam needs well-developed infrastructure. Though Vietnam’s infrastructure is improving, the article still suggests Vietnam will need about half a trillion USD in infrastructure investments over the next five to ten years. Investment from Japan and the China-led Asian Infrastructure Investment Bank will be key in this regard.

To learn more about Vietnam’s competitiveness in manufacturing, check out the full article in the link below:

Vietnam's Place in the Asian Century – Anirban Lahiri, Frontera News

We’re constantly scanning the web for top manufacturing stories and news. If you’d like to submit an article for consideration for our weekly Best in Manufacturing, send us a message and let us know