Best in Manufacturing – May 13, 2018

Each Sunday, we publish a list of top articles and other content related to manufacturing in areas like quality control, product development, supply chain management, sourcing, auditing and law.

This will be my last Best in Manufacturing. The column will continue, but under different authorship. Thanks everyone for reading so far and we hope you continue to enjoy Best in Manufacturing!

1. Your Chinese supplier, aka your greatest competitor

After finding a Chinese supplier, you might be tempted to think it’s somewhat beholden to you. The supplier’s representatives have promised a long, mutually beneficial relationship, full of profit and free from setbacks.

Unfortunately, dealing with Chinese suppliers doesn’t always proceed as planned.

You may have designed, provided specifications for, and even trained the supplier to make your novel item. Yet potentially, the supplier’s aim is to acquire product knowledge and then use it to manufacture your products…and compete with you.

The Chinese supplier may be willing to initially lose money on making your product just so it gains access to how to make it. The supplier could then rebrand the product, sell it through ecommerce channels and undercut the price you’re offering.

Think about it: who else knows your product as well as (if not better) than you? Who’s actually doing all the manufacturing? The clear answer is your supplier. After enough production runs, the supplier may even make improvements to your original design and force you out of the market. Customers will come to associate your hijacked product with the brand of the Chinese supplier. That’s rough.

Very likely, you don’t want to train your competitor on how to best you in the business of your own product. That’s why, as this featured article advises, you need contracts to protect your company and goods.

Protecting your product and designs

After a transgression has taken place against your company, you probably won’t come to the most favorable terms on a manufacturing contract. As mentioned by the author of this featured article:

You want a contract to memorialize your good relationship.

The best time for a contract that has the most favorable terms for you is when trust is at its highest. At the opportune moment, you want to solidify everyone’s promises of goodwill and protect yourself (see #2) with something concrete, for example, like an NNN agreement.

Make no mistake: there are great Chinese suppliers out there that don’t want to steal your designs and products. But it’s essential to remain vigilant of your supplier because they might become your greatest competitor.

Take a precautionary measure and educate yourself by reading this great and informative post:

Chinese Suppliers: Competitors not Friends – Dan Harris, China Law Blog

2. The next “Airbnb” for manufacturing – in China

For some of us, it’s hard to imagine how we used to survive without Airbnb or Uber. These online platforms have made it easier than ever to find what you need, when you need it—whether it’s a place to stay or a taxi.

If you’re an importer manufacturing in China, you might soon be wondering how you ever got by without Fictiv, a platform proclaiming to be the next “Airbnb for manufacturing”.

The platform matches manufacturers who need rapidly produced parts and prototypes with a network of over 200 factories in the U.S. and China. Fictiv claims their platform can cut lead times from months or weeks to just hours and days—3D printed parts can be available same-day, and injection molded parts can be ready in 10 days. They also provide services for urethane casting and CNC machining and hope to move beyond just rapid prototyping into larger volumes as they expand.

Fictiv isn’t the only new platform promoting “on-demand manufacturing” (see #3). But they do seem to be unique in their focus on China. They just opened an office in Guangzhou to expand their network in China. And Sinovation Ventures, an investment firm headed by former head of Google China Kai Fu-Lee, is one of their biggest investors.

Fictiv’s network helps Chinese factories too, some of which are facing lower demand as China’s wages rise. Many of Fictiv’s customers so far include companies that make electric and autonomous cars, medical robotics and consumer electronics. These are just the sort of products China’s government is focused on promoting and investing in with the Made in China 2025 initiative.

Interested in taking advantage of Fictiv’s on-demand manufacturing model? Learn more about the platform in the link below:

Fictiv, The Airbnb Of Manufacturing, Raises $15 Million For Expansion In The U.S. And China – Amy Feldman, Forbes

3. The manufacturing hub responsible for iPhone creation: iPhone city

The iPhone is easily one of Apple, Inc.’s most iconic products. Despite your preference of phone brand, it’s hard to deny the success of the iPhone. In the 2017 fiscal year, Apple sold a staggering 216.76 million iPhones.

The world may pay great attention to the phone and its success, but a question lingers. Where did all these iPhones come from?

There’s a good chance they came from a place called “iPhone City”.

Located in Zhengzhou, China, iPhone city is the result of the massive Foxconn iPhone factory that employs 350,000 people there. With so many people employed by a single factory concentrated in the same area, a mini-city popped up, complete with restaurants, dorms for workers, movie theaters, karaoke bars and more.

This featured article reports that the work in the factory is mundane and full of long hours and low wages. But workers say this is characteristic of jobs at factories. The work at Foxconn factory isn’t so different from their experiences at other factories.

Complete with scores of pictures and quotes from workers, this featured article offers great insight into iPhone city and its denizens. If you want an in-depth look at iPhone city, check out the full article in the link below:

Inside 'iPhone City,' the Massive Chinese Factory Town Where Half of the World's iPhones are Produced – Harrison Jacobs, Business Insider

4. TEDx talk: the impact of fast fashion

In case you’re unfamiliar with fast fashion, it’s essentially a way of expressing how fashion designs move from the catwalk to stores at breakneck speeds so as to capitalize on the latest trends.

At a glance, fast fashion might not seem so negative. After all, consumers are getting the hippest, latest clothes quickly. Retailers are benefitting because they’re making sales. Value, it seems, is being generated by fast fashion.

While the coffers of retailers are enriched and the wardrobes of consumers filled, both the people making the clothes and our planet at large pay a major price.

As this TEDx talk points out, some general consequences of the fashion industry include:

- Contributing to an estimated 10 percent of the world’s carbon footprint

- Polyester, a microplastic-based material 4x as labor intensive as cotton, ending up in oceans and landfills

- 4 billion pounds of textile waste in landfills

- And more

Since fast fashion exacerbates consumption, the demand for raw materials and the toll on our planet, the above mentioned statistics will only grow in severity.

To learn more about these statistics and fast fashion’s impact, be sure to watch this TEDx talk, provided above and in the link below:

Fast Fashion’s Effect on People, The Planet, & You – Patrick Woodyard, TEDx University of Mississippi

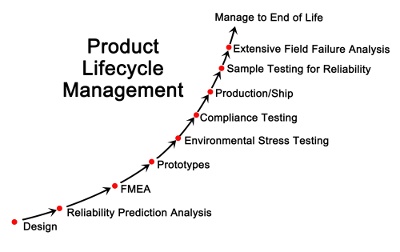

5. Environmental compliance in product lifecycle management

Products with hazardous substances in them pose a threat to consumers. Unfortunately, keeping track of all those substances isn’t always the simplest task. And to complicate matters further, the list of dangerous substances deemed illegal and of serious concern constantly evolves.

Ensuring compliance with laws that outlaw certain substances, such as REACH, is best addressed at an early stage of product development, rather than retroactively. As this featured article points out, using a product lifecycle management (PLM) system helps in this effort to stay compliant.

To address issues with problematic substances at the beginning of a product’s lifecycle, companies need to make visibility of data about those substances more visible to designers and engineers so they make smart sourcing and development choices. A PLM system gives them the compliance information they need, when they need it.

As customers increasingly demand environmentally friendly products, adherence to laws limiting and prohibiting certain substances will need to be a more essential part of a product’s development. Not only is the consumers’ health at risk, but failure to comply could result in public backlash and penalties.

And to avoid these complications, you need to stay on top of your compliance data. To learn more about a PLM system and how it can help with environmental compliance, check out the featured article in the link below:

Incorporating Environmental Compliance Into The Early Stages Of The Product Development Process – Cyndi Kuka & Chuck Cimalore, Manufacturing Net

We’re constantly scanning the web for top manufacturing stories and news. If you’d like to submit an article for consideration for our weekly Best in Manufacturing, send us a message and let us know.