The first time we started to talk about textile colorfast was in 1916. It is an old story in the textile industry! Since then some standard tests have been created to detect color bleeding issues. Recently the issue has been detected in several shipments, including shirts, suitcases and even sneakers. How can we test textile color fastness?

The first time we started to talk about textile colorfast was in 1916. It is an old story in the textile industry! Since then some standard tests have been created to detect color bleeding issues. Recently the issue has been detected in several shipments, including shirts, suitcases and even sneakers. How can we test textile color fastness?

Manufacturing and Quality Control blog

- Home

- Manufacturing and Quality Control blog

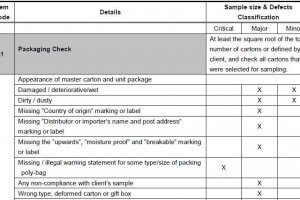

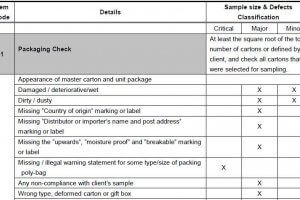

While an importer's specs and list of expected product defects are vital to perform an adequate inspection, reputable inspection firms like AQF have internal inspection checklists for any range of products.

While an importer's specs and list of expected product defects are vital to perform an adequate inspection, reputable inspection firms like AQF have internal inspection checklists for any range of products. Nowadays, a lot of third party inspection companies are increasing their inspectors' skills and training how to use special tools to check product quality. For example, during a soft-goods or textile inspection the most important tools that will be used are newton meters, metal detectors, barcode scanners, pantone books, etc. But one of the most important for a soft-goods inspection (along with ceramics, toys, and many other items!) is a grey scale in order to evaluate the color shading or staining.

Nowadays, a lot of third party inspection companies are increasing their inspectors' skills and training how to use special tools to check product quality. For example, during a soft-goods or textile inspection the most important tools that will be used are newton meters, metal detectors, barcode scanners, pantone books, etc. But one of the most important for a soft-goods inspection (along with ceramics, toys, and many other items!) is a grey scale in order to evaluate the color shading or staining.  Already, we have introduced

Already, we have introduced

As the process seems not to be clear for all our clients, we have decided to shed light on this important subject.

As the process seems not to be clear for all our clients, we have decided to shed light on this important subject. Meeting with clients, I noticed that many misunderstand the meaning of “QC checklist ” in the QC process. this word is often used inaccurately, so what’s the real definition and what does a QC checklist contains?

Meeting with clients, I noticed that many misunderstand the meaning of “QC checklist ” in the QC process. this word is often used inaccurately, so what’s the real definition and what does a QC checklist contains?