A Pre-Shipment Inspection (PSI) is a quality control procedure carried out at a supplier’s premises by either your QC department or an independent quality control agency contracted to you. It’s a commonplace check within the consumer goods industry in particular and helps importers, traders, wholesalers, and retailers guarantee the quality of goods before they are shipped. It guards against any nasty surprises, and means you know your goods are in working order long before you take delivery — pretty useful if your supplier is halfway around the world.

Manufacturing and Quality Control blog

- Home

- Manufacturing and Quality Control blog

La calidad de productos cerámicos se evalúa difícilmente porque casi siempre habrán defectos. La principal razón detrás de eso es que se trata de un material natural y debido a su naturaleza delicada, su producción implica actos manuales. Sin embargo, es imperativo explicar claramente, al proveedor, el tipo de calidad requerida para sus productos cerámicos. Con esta intención, el comprador debe tomar en consideración dos puntos: la conformidad del material con los estándares y los requerimientos y estándares cosméticos.

La calidad de productos cerámicos se evalúa difícilmente porque casi siempre habrán defectos. La principal razón detrás de eso es que se trata de un material natural y debido a su naturaleza delicada, su producción implica actos manuales. Sin embargo, es imperativo explicar claramente, al proveedor, el tipo de calidad requerida para sus productos cerámicos. Con esta intención, el comprador debe tomar en consideración dos puntos: la conformidad del material con los estándares y los requerimientos y estándares cosméticos. The overall appearance of a product is an important criteria in the purchasing decision. For hardline, electronics or electrical products, one of the most common defects identified during inspection are scratches. Some are obvious and others more discreet; therefore, during an inspection, the QC will classify each one of them, making the difference between major and minor scratch marks. When can scratch marks appear? How do we go about classifying this defect?

The overall appearance of a product is an important criteria in the purchasing decision. For hardline, electronics or electrical products, one of the most common defects identified during inspection are scratches. Some are obvious and others more discreet; therefore, during an inspection, the QC will classify each one of them, making the difference between major and minor scratch marks. When can scratch marks appear? How do we go about classifying this defect? Garment manufacturing

Garment manufacturing Una gran oferta de servicios de inspección son ofrecidos a los compradores con el fin de controlar la mercancía a lo largo del proceso de producción y previo a su embarque y cada uno de estos servicios permiten lograr objetivos específicos en cuanto al control y al aseguramiento de calidad. Entonces para qué sirve una inspección durante la producción y cuáles son sus objetivos?

Una gran oferta de servicios de inspección son ofrecidos a los compradores con el fin de controlar la mercancía a lo largo del proceso de producción y previo a su embarque y cada uno de estos servicios permiten lograr objetivos específicos en cuanto al control y al aseguramiento de calidad. Entonces para qué sirve una inspección durante la producción y cuáles son sus objetivos?

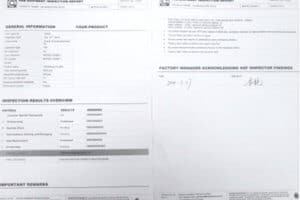

After performing the quality inspection in the factory, the inspector prepares the draft report on-site and reviews with the factory manager. However a draft report is different from the final report and the buyer should be fully aware of the differences to avoid any misunderstanding of the quality inspection result.

After performing the quality inspection in the factory, the inspector prepares the draft report on-site and reviews with the factory manager. However a draft report is different from the final report and the buyer should be fully aware of the differences to avoid any misunderstanding of the quality inspection result.