Each Sunday, we publish a list of top articles and other content related to manufacturing in areas like quality control, product development, supply chain management, sourcing, auditing and law.

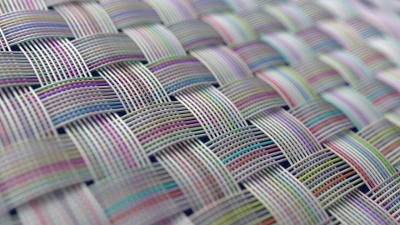

1. How 3D knitting could disrupt the apparel industry—and already has

I like the color red. I feel it suits me. You might prefer blue, green, black, white or some other color. But what if all the clothes you could buy were red, with no options for differentiation and customization available to you?

Thankfully, the world of fashion isn’t like this. Countless designers and fashionistas exist that contribute to the presence of apparel choices whenever you go into a retailer or shop online. For even more differentiation, sure, you can get customized clothing via a tailor…but you might have to pay much more than you would for mass-produced clothing.

Thankfully, the world of fashion isn’t like this. Countless designers and fashionistas exist that contribute to the presence of apparel choices whenever you go into a retailer or shop online. For even more differentiation, sure, you can get customized clothing via a tailor…but you might have to pay much more than you would for mass-produced clothing.

Yet in the future, that may change. Advances in 3D-knitting, digital body scanning and augmented reality technology could pave the way for customized clothing in much greater numbers and at a price cheaper than that of tailors.

Just imagine: you’re at home and realize there are holes in your shirt. You decide you want a new shirt that’s the same size as the one you’re wearing, but in a different color and with a decal on the front. You use something like Amazon Echo or your phone to take your measurements, pick your desired decal, submit it to the platform you’re using, and receive your 3D-knitted product in a few days.

Or maybe, you want your product quicker and desire some feedback from store clerks on how your potential design looks. So you go to a retailer and have your apparel printed there, in a way similar to how this featured article reports:

Some brands are beginning to explore pairing scanning technology with augmented reality. Adidas has showcased an in-store device that scans a shopper to determine their measurements and then projects product designs onto their body via light sensors. Using hand gestures, the shopper can manipulate the projection and finalize the design before it is 3D-knitted in-store.

How customization might affect the mass market

Not every consumer really wants, or needs, highly customized products. Some people are content to just buy predesigned clothes. However, for those that do customize products, they’ll help apparel companies create a new generation of clothes because of the data they provide, which might influence mass-produced apparel.

Overall, customization could bring a few advantages, such as:

- More customer data: this information can be used to inform other product developments, anticipate trends and better deliver what mainstream customers want

- Less waste: since clothes will be made to order with 3D-knitting, seamstresses won’t need to cut and waste swaths of fabric

- Fewer returns: ideally, clothes that are custom made will be exactly to their purchaser’s liking and won’t get returned

The question lingering on my mind now is that if the clothes are 3D-knitted and customizable, will these developments also reduce garment defects or potentially lead to more?

If you’d like to learn more about customized clothing and how it might change the apparel industry, check out this featured article in the link below:

Disrupting Your Closet: How Customized Clothing Can Remake the Apparel Industry – Maria Lernerman and Chris Mack, Harding Loevner

2. Getting started with drop shipping

Drop shipping – what is it? Well, I had no idea at first, and thankfully it doesn’t have anything to do with literally dropping your products on the ground. Drop shipping is a means of supply chain management. With this approach, importers and retailers don’t keep stock of items. Instead, their goods are directly sent from a wholesaler or supplier to a customer.

For small to medium-sized businesses, drop shipping might hold some appeal on account of how a giant part of the importing equation (logistics) is removed. With lower overhead costs, importers can use those savings on other aspects of their company.

But having your supplier handle this can eat into your margins. Although you won’t have to control inventory or ship products, for example, you might make a little less money than if you were to manage these responsibilities yourself. And since you’re slightly more removed from the supply chain, it might be harder to determine the presence of and limit product defects in your orders.

This featured article mentions some fees you might need to pay to get your drop shipping venture up and operational:

- Per-order fees: depending on what it is you’re selling, you could face additional fees of $2-5 USD per item.

- Minimum order sizes (also referred to as a “minimum order quantity – MOQ”): in order for a supplier to take your order, you have to buy a certain amount of product.

Curious about drop shipping? Check out this article to learn about the pros & cons of drop shipping and some other essential information about this supply chain management technique:

Drop Shipping 101: How to Pick a Great Supplier – Jason Acidre, TechInAsia

3. The supply chain control tower

When you’re landing at an airport, it’s not just a one-person operation. The pilot at the front of your plane isn’t the only one working to get it safely on the ground – there’s also a dedicated team of people in the control tower helping orchestrate the whole show.

Your supply chain isn’t a plane – that just sounds silly. But just like a plane, your supply chain needs coordination and sight of what’s going on to effectively function.

Your supply chain isn’t a plane – that just sounds silly. But just like a plane, your supply chain needs coordination and sight of what’s going on to effectively function.

The author of this featured article mentions the concept of the “control tower” in your supply chain so as to make use of all the data in it and gain more visibility. And this issue isn’t one to gloss over. He refers to the KPMG Global Manufacturing Outlook survey, which references how almost half of the supply chain leaders questioned feel that supply chain visibility is elusive.

To address this issue, the author suggests using the following “control tower architecture”:

- Integration Layer: this layer handles information coming from external partners, remote data sources and your back-end systems

- Visibility Layer: this layer aggregates and normalizes global data from your internal and external operations in order to report, create metrics and provide business intelligence

- Execution Layer: this layer contains applications, like for demand planning, order execution & fulfillment and more, that use the data provided by the visibility layer

- Analytics Layer: this layer will help you perform root cause analysis and create simulations and “what if” scenarios

And by utilizing this architecture,

…[one company] was able to reduce their planning cycle time by 75%, improve on-time delivery in full by 11%, and reduce finished good inventory by 11%.

Those are some pretty great results, to say the least. So want to find out more about gaining visibility in your supply chain? Check out the full article that covers this topic by following the link below:

Take Control of Visibility into Your Supply Chain – Rob Barrett, Industry Week

4. [Podcast] Chinese factories in Africa

China is expanding its international presence not just to the West and Middle East through its One Belt, One Road initiative. Bold Chinese entrepreneurs are setting up factories in Africa, where competition and labor costs are relatively low.

You might even be wearing clothes made in Africa, not Asia, right now. This podcast episode mentions how companies like Kohls and Levis buy clothing from Chinese suppliers with operations in the tiny country of Lesotho. But in some cases, the Chinese-owned factories decide not to export the African-made products to foreign markets. Instead, in the absence of fierce competition, they sell them domestically.

The episode also discusses why many Chinese entrepreneurs, and not Americans, are taking up opportunities in Africa. Additionally, the episode features stories of Africans who have used these opportunities to improve their lives, the lives of their communities and to become successful in business.

Will a greater portion of global manufacturing output come from Africa in the years to come? Listen to this podcast and then let us know your thoughts in the comments below!

To listen to this detailed, extensive podcast episode, follow the link below:

The Hardscrabble Business of Chinese Manufacturing in Africa – Irene Yuan Sun and Sarah Green Carmichael, Harvard Business Review

5. Augmented reality in logistics and manufacturing

Last year, I wrote about how augmented reality (AR) is augmenting manufacturing.  And that development hasn’t ceased. AR holds tremendous potential for manufacturing and other parts of the supply chain, like logistics.

And that development hasn’t ceased. AR holds tremendous potential for manufacturing and other parts of the supply chain, like logistics.

In the realm of manufacturing, for example, Google Glass can help workers quickly communicate with one another and understand where to place parts. Instead of having to go back and forth between looking at a computer with assembly instructions to the product in front of them, workers can simply don Google Glass and look directly at the product as AR technology overlays instructions.

Regarding logistics, this featured article reports that AR applications could optimize transport and assist with making warehousing more efficient. AR could help:

- Scan and identify packages and confirm their destination location

- Determine where goods need to go in a storage facility

- Display digital directions during delivery

- And more!

Want to know about the other ways that AR is changing the world of manufacturing and logistics? Check out the full article in the link below:

3 Ways AR Is Transforming Manufacturing and Logistics – Michael Park, Venture Beat

We’re constantly scanning the web for top manufacturing stories and news. If you’d like to submit an article for consideration for our weekly Best in Manufacturing, send us a message and let us know.