Chances are you’ve heard of “REACH” and “RoHS” if you’ve considered importing goods into the EU over the past decade.

Chances are you’ve heard of “REACH” and “RoHS” if you’ve considered importing goods into the EU over the past decade.

But despite the prevalence of these acronyms, the specific requirements of these regulations are still a mystery to many importers. Who needs to comply with which regulation? What are importers responsible for under REACH vs. RoHS? And what are the potential consequence of noncompliance.

It doesn’t help that the regulations are continually changing. New compliance requirements under RoHS 2 and RoHS 3 will be implemented in July 2019 and will impact all producers regulated under the standard. New restricted substances, marking requirements and regulated product types have been added to the directive.

And the European Chemicals Agency (ECHA) recently announced it will quadruple the number of REACH compliance checks it conducts, making REACH testing and compliance more important than ever.

So what requirements do you need to comply with? Let’s take a look at each of the standards in detail so you can be sure your goods are fully compliant for the EU market.

What is REACH?

Regulation (EC) No 1907/2006, commonly known as REACH, was adopted in the European Union to protect humans and the environment from chemical risks. REACH stands for Registration, Evaluation, Authorisation and Restriction of Chemicals. The REACH regulation came into force on June 1st, 2007 and has since become a major requirement for regulatory compliance in the EU.

REACH requirements apply to the production and use of all chemical substances. You might not think your product includes chemicals. Products like clothing and furniture certainly don’t intuitively fit into the “chemicals” category.

But REACH requirements apply not only to chemicals used in industrial processes, but also to chemicals in products consumers use throughout their daily lives. REACH requirements apply to consumer goods like cleaning products, paints, clothes, furniture, toys and electrical appliances.

As an EU regulation, REACH requirements and enforcement are consistent across all 28 EU member states and are immediately enforceable upon enactment.

What are the REACH SVHCs?

REACH requirements regulate the use of chemical  “substances of very high concern”, commonly abbreviated as SVHCs.

“substances of very high concern”, commonly abbreviated as SVHCs.

Substances typically classified as a REACH SVHC include those which:

- Are carcinogenic, mutagenic or toxic for reproduction (together known as CMR substances)

- Are persistent, bioaccumulative and toxic (PBT substances), meaning harmful chemicals that do not break down easily in the environment

- Pose other serious hazards to human health or the environment identified on a case-by-case basis

The EU controls the use of REACH SVHCs through three classification stages:

- Candidate List: Substances that may eventually be included in the Authorisation List. These substances should not be present in a concentration of more than 0.1 percent w/w (weight per weight) in a product. Importers with products containing higher concentrations may need to provide a safety data sheet for compliance. This list currently includes 197 substances.

- Authorisation List (Annex XIV): Substances importers cannot use or import into the EU without prior authorization from the ECHA after a set “sunset date”. This list currently includes 69 unique substances.

- Restriction List (Annex XVII): Substances presenting an unacceptable risk to human health or the environment. Use of these substances is fully restricted, and importers cannot receive authorization to use these substances.

Importers can still use substances included in the Candidate List or Authorisation List in their products if they comply with the EU’s compliance requirements. But the EU generally encourages importers to find ways to substitute and phase out these substances in their products in the long term.

Further REACH compliance requirements

Companies that import over one metric ton of REACH SVHCs a year are also required to register with the ECHA. This registration dossier should communicate hazard information and a risk assessment of the use of the substance.

Importers often also choose to provide a REACH certificate to their customers as part of their compliance efforts, but REACH certification is not an official legal requirement. This REACH certificate typically includes REACH testing results and a self-assessment of compliance.

What is RoHS?

Like REACH, the EU’s Restriction on Hazardous Materials (RoHS) Directive also regulates the use of chemical substances in products.

Like REACH, the EU’s Restriction on Hazardous Materials (RoHS) Directive also regulates the use of chemical substances in products.

The primary aim of the RoHS Directive is to reduce the volume of toxic electrical waste. RoHS is also closely related to the Waste Electrical and Electronic Equipment Directive (WEEE), which sets recycling targets for electrical goods.

Unlike REACH regulations that apply to a wide variety of products, RoHS requirements only apply to electrical products. But this category still includes a wide range of electrical products, equipment, cables and electrical components.

Products subject to RoHS include:

- Home appliances

- Small household appliances

- IT and telecommunications equipment

- Consumer electronics

- Lighting fixtures

- Electrical and electronic tools (except stationary, large industrial tools)

- Electric toys and sports and leisure equipment

- Medical devices (except all implanted and infected products)

- Monitoring and control instruments

- Automatic output devices

- Other electrical and electronic equipment

RoHS is an EU “directive”, rather than a regulation like REACH. An EU directive is a legislative act that sets a goal that all EU countries must achieve. But each country must devise their own laws on how to reach the goal. While countries might differ in their implementation and enforcement of RoHS, the restricted substances and their limits are largely consistent across the EU.

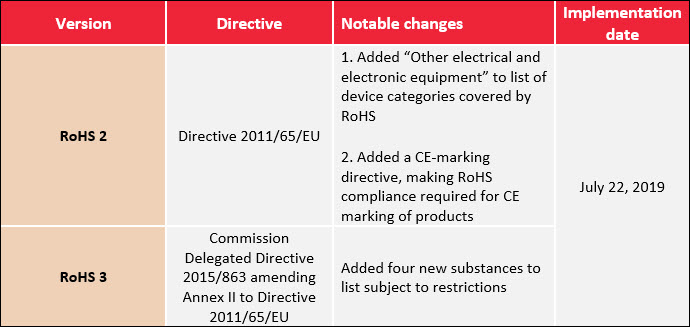

The original RoHS Directive, Directive 2002/95/EC, has undergone two revisions since its inception in 2002:

- Directive 2011/65/ EU, “RoHS-Recast” or “RoHS 2”, which replaced Directive 2002/95/EC

- Directive 2015/863, “RoHS 3”, which amended Annex II of RoHS 2

Hazardous substances restricted under RoHS

The RoHS Directive restricts the use of six hazardous  substances in electrical products, including:

substances in electrical products, including:

- Cadmium (Cd): < 100 ppm

- Lead (Pb): < 1000 ppm

- Mercury (Hg): < 1000 ppm

- Hexavalent Chromium: (Cr VI) < 1000 ppm

- Polybrominated Biphenyls (PBB): < 1000 ppm

- Polybrominated Diphenyl Ethers (PBDE): < 1000 ppm

Restricted substances may not compose more than 0.1 percent of any “homogeneous” material in the product to comply with the standard. This is the equivalent of 1000 ppm (parts per million). The one exception is for cadmium, which is limited to 0.01 percent or 100 ppm.

A homogenous material means a single substance that cannot be separated by mechanical actions such as unscrewing, cutting, crushing, grinding or abrasive processes. You might need to test multiple materials in your product if they could each contain restricted substances.

RoHS 2 and RoHS 3 updates

The original RoHS Directive restricts the use of the six hazardous substances above. Its replacement, RoHS 2, extended the list of electrical products RoHS covers.

RoHS 2 also makes RoHS compliance a requirement for CE marking and requires electrical, electronic and electromechanical (EEE) manufacturers to affix a CE mark to their finished products to show compliance. In doing so, the manufacturer declares that the product meets all the legal requirements for sale throughout the European Economic Area (EEA).

The latest amendment, sometimes called “RoHS 3”, will be implemented on July 22, 2019 and will add four new hazardous substances to the existing list:

- Bis (2-Ethylhexyl) phthalate (DEHP): < 1000 ppm

- Benzyl butyl phthalate (BBP): < 1000 ppm

- Dibutyl phthalate (DBP): < 1000 ppm

- Diisobutyl phthalate (DIBP): < 1000 ppm

These four substances are all phthalates used to soften plastics and can be found in cables, wiring, vinyl, synthetic rubber, adhesives, paints and other materials. These phthalates are already restricted in toys at a stricter limit under REACH standards, so this new requirement doesn’t apply to toys under RoHS.

Medical device importers have an additional two-year grace period to become compliant with the RoHS 3 requirements to ensure consumer safety during the transition.

Ensuring compliance with REACH vs. RoHS testing requirements

Ensuring compliance with REACH vs. RoHS testing requirements

Manufacturing goods in Asia can involve many different suppliers, ranging from raw materials suppliers to parts manufacturers. As a result, determining who is responsible for ensuring REACH and RoHS compliance can be difficult.

Manufacturing goods in Asia can involve many different suppliers, ranging from raw materials suppliers to parts manufacturers. As a result, determining who is responsible for ensuring REACH and RoHS compliance can be difficult.

The company that imports products into the EU is responsible for ensuring regulatory compliance with both REACH and RoHS requirements. As an importer, you’ll be held legally accountable if your product is later found not to meet the legal requirements you’ve declared compliance with.

The RoHS 2 Directive goes one step further and extends responsibility for regulatory compliance to include all “producers” in a supply chain.

The RoHS Directive defines the “producer” as anyone who:

- Manufactures and distributes electronic equipment under their own brand

- Resells equipment produced by other suppliers under their own brand

- Is responsible for importing or exporting applicable equipment into a nation covered by the RoHS Directive

What are the potential consequences of noncompliance?

For one, the policy of “no data no market” places the burden of gathering information and assessing risk of the substances in their products on the manufacturer and the importer. Noncompliant products cannot be distributed in the EU market.

Each EU member state has its own enforcement penalties. But certain federal-level offenses can lead to eight years in prison and a fine of 55,000,000 EUR.

REACH vs. RoHS testing requirements

Testing is not strictly mandatory for either RoHS or REACH compliance. But there is significant risk associated with skipping RoHS and REACH testing of your goods.

While Chinese and other Asian manufacturers are generally familiar with RoHS and REACH requirements, many of them have little visibility into or control over their own supply chain.

Sub-contracting is common and often necessary to acquire necessary raw materials and components. But manufacturers rarely have robust incoming quality control or auditing procedures to verify suppliers and their supplied goods.

Independent verification of product samples and finished goods is therefore a must for importers to reduce their risk and avoid liability issues. Lab testing is typically the best way to detect restricted substances and ensure the regulatory compliance of your goods. You should also obtain materials declarations and certificates of compliance for all suppliers in your supply chain.

For complete EU compliance, importers of electrical products need to perform testing for RoHS 3 requirements and all applicable requirements of the REACH regulation. RoHS testing alone is not enough to ensure REACH compliance for electrical products.

Common REACH testing methods

There are two common approaches to REACH testing:

- REACH SVHC screening: A quick indication of the presence of any SVHCs and their location within the product

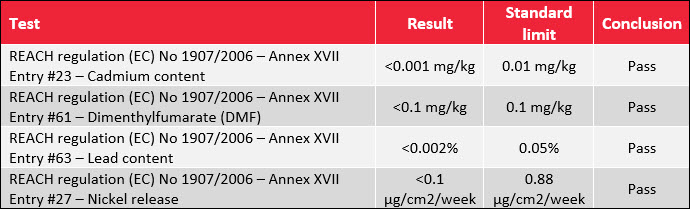

- Testing according to Annex XVII Restricted List: Test for specific restricted substances according to your product type

Most importers start with a “screening” for REACH and RoHS testing, rather than a full quantitative analysis.

Screening is a more cost-effective option, as it primarily tests the parts of a product with the highest risk of containing restricted substances. There’s typically no need for further analysis if the screening doesn’t reveal any SVHCs.

This screening can include most or all substances on the REACH Restricted List and Authorised List for a total of over 180 substances. Or you can select specific substances to test for based on your product type and appetite for risk.

The testing report you receive from an independent laboratory should include the result for each test in comparison to the relevant standard:

Common RoHS testing methods

The RoHS testing process is similar to that for REACH testing:

- X-Ray fluorescence (XRF) screening: A quick indication of the presence of any hazardous substances and their location within the product

- Chemical analysis, if XRF screening highlights any potential nonconformities: Verifies any nonconformities found during XRF analysis

Importers will commonly start with the XRF screening and proceed from there according to the results.

You might want to test product samples before mass production begins to ensure the compliance of parts and materials to be used in the finished products. If your budget and timeline allow, lab professionals suggest conducting testing of finished production units, ideally first articles, before shipment as well.

Conclusion

By now you can tell that REACH and RoHS differ quite a bit in their purpose and scope. But the process to ensure REACH and RoHS compliance is largely similar for importers.

Before importing into the EU, be sure to carefully review the regulations that apply to your product. Once you’re ready to move forward with production, verify your supplier’s goods, rather than simply taking their word for it. RoHS and REACH testing will give you independent verification of the quality and safety of your supplier’s goods.

When it comes to REACH and RoHS compliance, don’t take a risk you can’t afford. Hiring a reliable and professional independent laboratory can help you detect any restricted substances in your product before they reach the EU and put your business at risk.

How do you ensure REACH and RoHS compliance? Share your experiences in the comment section below!