Each New Year bring with it a new hope for progress. But instead of piling into a gym or committing to read two books a month, importers and supply chain professionals are facing greater challenges in 2018.

Each New Year bring with it a new hope for progress. But instead of piling into a gym or committing to read two books a month, importers and supply chain professionals are facing greater challenges in 2018.

With brick-and-mortar stores declining slowly but surely, ecommerce is expected to account for 17 percent of all U.S. retail sales by 2022. And according to Salesforce, “70 percent of consumers say technology has made it easier than ever to take their business elsewhere”.

Consumer preferences are changing rapidly. Standards for service and products are reaching new heights. And if you’re an importer or supply chain professional, 2018 is your year to embrace these changes to better serve your customers. This year presents a chance for you to adapt early and gain an edge over your competitors. With that in mind, here are five New Year’s resolutions to help you meet your goals:

1. Nurture your relationships: Customers, suppliers and QC team

Consider the key players in your supply chain that are integral to your business. What relationships could you work to further develop or improve that will have an immediate, positive impact on your success?

If you’re like most importers, your customers are your greatest concern. Your suppliers are a close second. And your QC team is a bridge that closes the gap between what your customers expect and what your suppliers can provide. All three are instrumental in empowering you to succeed.

Ask for customer feedback (and actually listen!)

It may seem like common sense. But there’s no substitute for direct customer feedback when it comes to informing product or service changes. Just ask executives at Lego, a company with 30 percent declines in sales year-on-year and $800 million in debt in 2003. By hiring product designers who were lifelong customers of their products, they rescued Lego from the brink of bankruptcy, surpassing $1 billion in sales for the first time in 2015.

You don’t have to hire your customers to get their input on your product. Simply taking the time to ask customers to share what they like or dislike about your product can give you valuable feedback on ways to improve. Some of the best ways to get customer feedback are:

You don’t have to hire your customers to get their input on your product. Simply taking the time to ask customers to share what they like or dislike about your product can give you valuable feedback on ways to improve. Some of the best ways to get customer feedback are:

- Customer surveys – these can work well provided you’re asking the right questions and structuring your survey to avoid response bias.

- Post-sale automated emails to elicit feedback – particularly if you’re a Shopify or Amazon seller, automated messaging software like Feedback Genius can help you get customer feedback with very little effort.

- Usability testing – use a service like usertesting.com to hire people similar to your customers to test your product and tell you about their experience with it.

Even if you’re selling commoditized goods, customer feedback could still lead to improvements in service that help you differentiate from your competitors.

Collaborate more closely with your suppliers

A 2012 McKinsey survey of more than 100 large global companies found that those that demonstrated deep collaboration with their suppliers grew their earnings before interest & tax (EBIT) at twice the rate of their peers.

Boeing collaborated with their supplier to innovate and develop a better product. Nordam, a manufacturer of aerospace parts and systems, developed the first-ever composite window frame for Boeing’s 787 Dreamliner. The frame was stronger but almost 50 percent lighter than traditional aluminum frames.

What does this mean for importers and supply chain professionals? Whether you have targets for cost reduction, quality improvement, lead times or other performance metrics, don’t overlook the role of supplier collaboration in helping you reach your goals. For example:

- Do you have suppliers that need to meet particular retailer compliance standards? Discuss a corrective action plan with your suppliers to address compliance issues over time.

- Do you need your supplier to help you develop a new product? Discuss your specifications and requirements with your supplier and reach an agreement on what’s achievable and various milestones for deliverables.

- Do you want to limit product defects in your shipments? Discuss which production processes are contributing to quality issues and possible ways your supplier can work to address them.

You’ll likely find it much easier to reach your goals when you and your supplier are aligned in the methods for achieving them.

Discuss progress and goals with your QC team

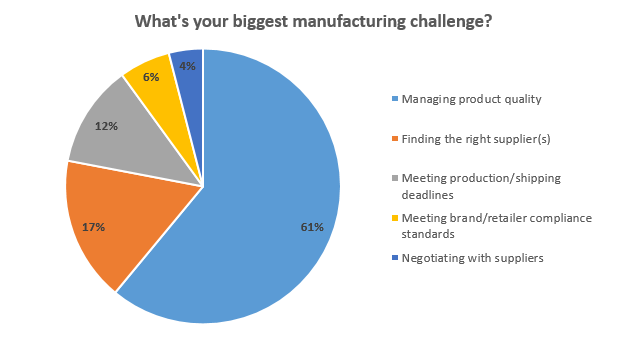

Over the last 15 months, we surveyed more than 1,400 importers and supply chain professionals that said they manufacture or source products from Asia. When we asked them, “What’s your biggest manufacturing challenge?” here’s what we found: The vast majority of importers and supply chain professionals working with suppliers in Asia identify product quality or meeting deadlines as frustrations. And whether you employ full-time staff or outsource QC to a professional third party, working more closely with your QC team will undoubtedly help you address these concerns. Here are a few action points to help you hit the ground running in 2018:

The vast majority of importers and supply chain professionals working with suppliers in Asia identify product quality or meeting deadlines as frustrations. And whether you employ full-time staff or outsource QC to a professional third party, working more closely with your QC team will undoubtedly help you address these concerns. Here are a few action points to help you hit the ground running in 2018:

- Review your product requirements with QC staff. Refine pre-shipment inspection criteria in your QC checklist. Or if you don’t already have one, develop one.

- Analyze historical reporting of product defects and quality issues and see if there are persistent problems you and your QC team can address with your supplier this year.

- If production or shipping delays have been an issue, consider routine inspections or production monitoring at your supplier’s facility to confirm your supplier is meeting production milestones and preventing delays.

It can be hard to get reliable insight into a supply chain, especially when your suppliers are based overseas. But open collaboration can help you build trust that leads to progress where transparency isn’t always available.

2. Cut out bad influences: Why it might be time to find a new supplier

For some importers and supply chain professionals, it may be time to cut ties with a supplier altogether. If efforts to collaborate and communicate openly with your supplier haven’t led to improvement and serious problems continue, finding a new supplier can be the best way forward. Here are some of the most common issues that lead to buyer-supplier breakups:

No accountability

Depending on where your suppliers are based, you may or may not have difficulty legally enforcing a manufacturing contract. But regardless, if your supplier refuses to accept responsibility for issues related to product quality, shipping delays or other key parts of your agreement, it may be time to give them the boot.

Misrepresented production capabilities

Some suppliers are guilty of over-promising and later under-delivering once they have your deposit for a purchase order. A couple ways to avoid this are to audit potential suppliers and request and approve a golden sample before working with them. But for current suppliers, it’s almost always better to find another than continue working with one that can’t meet you and your customers’ expectations.

Poor communication or unresponsiveness

It can be hard to gauge the quality and reliability of supplier communication, especially during the sourcing process. You may be talking with a sales representative, rather than someone at the factory that will be intimately involved with production. But if you find your supplier contact ignores your queries or outright lies about the status or quality of production, you may want to cut your losses and find a new supplier.

Unwillingness to cooperate with outside inspection

Importers are more likely to face supplier resistance to outside inspection by a third party than by their own staff (related: 4 Ways Importers Conduct Product Inspection [eBook]). But resistance to outside inspection of any sort is often a sign that the supplier may be hiding serious problems. If your supplier won’t allow pre-shipment inspection, consider finding one that will.

Unethical manufacturing practices

Legal developments in recent years, such as the U.S. ban on imports made with forced labor, have raised penalties for brands that work with unethical suppliers. And ethics extend beyond basic human rights violations to cover other areas such as overtime, workers’ insurance and other areas of employment.

If you’re unsure whether your suppliers meet local laws or retailer compliance frameworks, now is the time to be sure with an audit. Compel any noncompliant suppliers to improve, find new suppliers or risk losing distributors and other consequences.

If you’re looking for new suppliers this year, see what qualities to look for in a good one.

3. Save money: Limit defective product quantities and cut inspection costs

Waste is a virtually unavoidable byproduct of manufacturing. Excess material is cut away and discarded when manufacturing products like running shoes. Defects like soldering mistakes in printed circuit boards (PCBs) can render products unsellable.  And ultimately, these costs are passed on from the supplier to the buyer.

And ultimately, these costs are passed on from the supplier to the buyer.

But these forms of waste and the extra costs they generate for your business represent an opportunity. By reducing waste and saving money, you can pass these savings on to your customers and, in turn, become more competitive.

Supplier collaboration is key to detecting and resolving problems with production processes that contribute to defective products. And often just asking the right questions can reveal solutions to quality problems. For example:

- If you find mildew on garments or furniture with warped wood, you might ask your supplier how the materials and finished products are stored and packaged.

- If you find scratches or other damage in the surface of a plastic toy or other hardline product, it may be relevant to ask how the goods are handled at the factory.

By working with your supplier to address quality issues this year, you stand to receive goods that might otherwise be unsellable.

What role should QC inspection play in your supply chain?

Quality control inspection is a vital part of most supply chains. Without checking your products before they leave your supplier’s facility, you run the risk of unwittingly shipping defective or substandard goods to your customers. No matter how much you trust your supplier’s own internal QC practices, there’s no substitute for outside inspection.

But inspection is a cost, not a value-added activity. As W. Edwards Deming, an American statistician and engineer, famously put it: “Inspection does not improve the quality, nor guarantee quality. Inspection is too late. The quality, good or bad, is already in the product.”

Inspection, when used correctly, should always play a role in helping you catch issues you don’t want reaching your customers. But your aim in reducing costs and improving quality should be to prevent these issues from occurring in the first place. If you’re successful in working with your supplier to improve quality, you should come to depend less on inspection with time.

In the meantime, be sure to check out 5 Reasons for High Product Inspection Costs to learn what steps you can take this year to make your inspections more efficient.

4. Get organized: Improve QC documentation

Most importers and supply chain professionals can benefit from removing clutter and disorder from their daily routines in favor of more organization. And your product’s QC documentation is a great place to start.

When you’re juggling purchase orders, CAD drawings, tech packs, dimensional tolerances, testing requirements and inspection criteria it’s easy to lose track of important information. Often the negative consequence is that your supplier or QC team are following outdated specs or don’t have the documentation they need to understand your requirements.

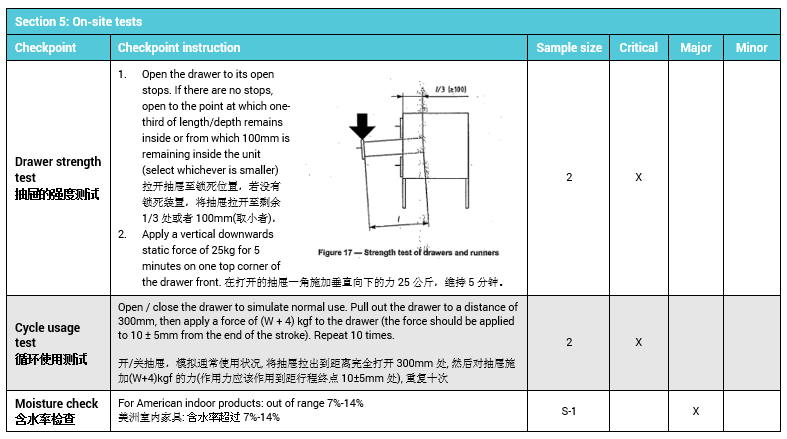

One way to effectively organize many different QC requirements is to consolidate them into a single, detailed document called a quality control inspection checklist, or QC checklist. You can include everything from product and packaging requirements, to known quality defects to report and checks and tests to perform during inspection. This document can be one of the most powerful tools for managing product quality and avoiding production and shipping delays. Just be sure to consult your supplier and QC team when developing a checklist for your product. Their feedback is essential to setting realistic expectations and seeing them realized in the finished goods.

This document can be one of the most powerful tools for managing product quality and avoiding production and shipping delays. Just be sure to consult your supplier and QC team when developing a checklist for your product. Their feedback is essential to setting realistic expectations and seeing them realized in the finished goods.

5. Travel! Maybe it’s time you paid a visit to your supplier

Feeling somewhat out of touch with your supplier in China, Vietnam, India or elsewhere overseas? Consider taking some time to visit. Besides the culturally eye-opening experience traveling abroad can be, meeting your supplier in person can give you the opportunity to:

- Tour your supplier’s facility and meet important contacts at the factory that you might otherwise not have access to

- Reaffirm your value as a customer

- Work through any pending quality issues or concerns you have for your product; and

- Discuss new product development

Most importers and supply chain professionals can benefit from vising their suppliers once a year. But depending on your purchasing volume and the status of your supplier relationship, you may want to visit your more frequently.

Conclusion

These five New Year’s resolutions for 2018 are, in fact, timeless. But they’re as relevant now as they’ve ever been. And firmly committing to them will help you tackle some of your greatest manufacturing challenges.

This is your year to strengthen your supply chain. How will you adapt to fit the changing tide of consumer habits and changes to the manufacturing landscape? Will you take a proactive approach, riding the wave to ever-greater levels of success? Or instead, will you be reactive, out of breath and paddling to catch up before being swept away?

Share this article by clicking the buttons below and get brainstorming with your collegues on how you can improve your supply chain this year!