Quality is critical when it comes to manufacturing, no matter the industry. Without it, it will be hard to position yourself in the industry. However, quality doesn't only mean using high-quality materials or cutting-edge technology during development. It also means having a solid plan before you even begin production.

To create a high-quality product, you must minimize difficulties and flaws that might jeopardize your product line. Therefore, it is essential to have a quality control system in place. Without it, you won't be able to find and fix any issues that will lead to a defective product.

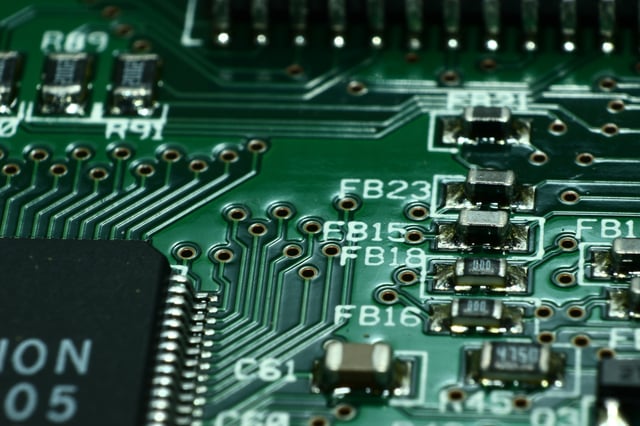

That is why we are here to talk about the key quality control methods in electronics manufacturing that you can use to ensure your product is as good as it can be.

Why Should You Care About Quality Control?

As we've just mentioned, you risk producing a faulty product without quality control. This can cost you far more than you saved by not implementing a quality control system in the first place. But there is more to it than that.

Quality control isn't just there to prevent problems; it's also there to help you make a better product. Quality control can help in the following ways:

- It will determine the longevity of your product: Quality control has a significant impact on the operating longevity of your products. Companies want to determine how long their items will be useful to the end customer so that they can provide warranty protection. In this situation, it might be expensive if the items fail before they should. Quality control guarantees that the consumer continues to use the product for the duration of its warranty.

- It prevents expensive product recalls: Without an effective quality control system, you risk sending out products that are not only defective but also hazardous. A few years ago, many companies had to recall lithium-powered devices due to their tendency to catch fire.

- You need it for compliance: Quality control is mandatory if you want to comply with government regulations. Medical and automotive industries sometimes have strict quality control standards since the product output may affect someone's life.

Recalls of combustible lithium batteries can be avoided entirely with proper quality control.

Never sacrifice quality control throughout the production process for the sake of your brand's image or customers. To help you ensure you have suitable quality control systems in place, we will try and cover some of the critical quality control methods in electronics manufacturing.

Choosing the Best Quality Engineer

An electronic quality control method’s success can only be ascribed to the quality engineer who created it. Engineering is a critical aspect of quality control in electronic production, and having a poor quality engineer on board can lead to disastrous outcomes.

Hiring the proper quality engineer is vital to the project's success, and you must ensure that you pick the correct individual for the position. This quality engineer must have the necessary knowledge, abilities, and experience to meet your electronics quality control requirements.

One of the required quality control methods in electronics manufacturing is simply having a skilled engineer look over your product.

You may also look at other electrical manufacturing businesses for quality engineers. The majority of these quality engineers are ready to collaborate with numerous firms. You can also have a third-party quality control company to conduct an inspection. This way, you will get an unbiased look at the state of your products.

Risk Management

If your company has a risk management system in place, you will be able to reduce setbacks and losses. This will be possible while keeping costs to a minimum. Risk management will also assist you in keeping up with your production schedule and meeting the deadline. Risk management is essential for every electronics manufacturing company because it reduces liabilities and identifies potential issues before they become a problem.

A risk management strategy should be included in all quality control plans, not just those for electronics. A risk management system is also required when developing a construction data form. This will allow you to concentrate your quality control efforts on the most critical aspects of your product. Risk management identifies issues before they become damaging to the production process.

Approval of the First Article

Before the manufacturing process can begin, a product must get a first article approval. It is a process in which the very first product that comes off the assembly line is examined. The main goal of this process is to compare the final product to the expected results. As long as the final product meets all quality criteria, your product will receive First Article Approval. This procedure is critical because you will be unable to begin mass production without it.

After receiving the first article approval, you will be able to begin mass production.

Technical Qualification Certificates

Although more of a bonus than a required step, quality certifications may cover holes that most quality control procedures ignore. It works for all industries - electronics, storage and warehousing, moving industry, and any kind of production.

This is the exact reason experts from nycministorage.com suggest that all companies get as many technical qualification certificates as possible. Certificates will address both the quality of the equipment and the capabilities of the workers that you employ.

Because they enhance the manufacturer's reputation, these might also be beneficial to branding efforts. Furthermore, since these certifications operate in a manner not dissimilar to that of a service guarantee, customer satisfaction will likely increase as well.

Quality Control Protects Your Business

Quality control is beneficial to businesses operating in any sector. Its purpose is not just to prevent problems; it also ensures that the quality of the products you create is high.

AQF verifies your Consumer Electronics quality, specifications, functions, safety, and compliance with relevant standards applicable to your product’s destination in Europe, USA and more. Contact us today or sign up for AQF Online to book your next service.

Editor’s Note: This article was originally published in JULY 2022 by James Garner. It has since been updated to reflect current best practices, services, and capabilities.