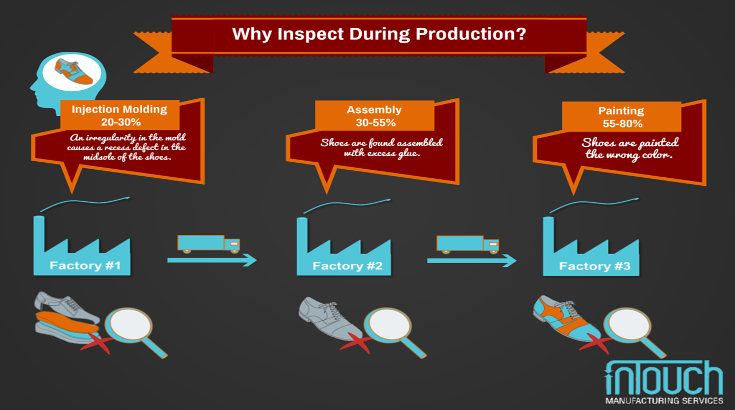

For many years, importers and retailers have been using third-party inspection companies to verify the quality of their products made in Asia. But inspecting products when they’re finished, or partially finished, can only do so much. That’s why a new trend is emerging in third-party inspection. Quality control is becoming more and more concerned with verifying the manufacturing PROCESS, not just the product.

Manufacturing and Quality Control blog

- Home

- Manufacturing and Quality Control blog

The term quality control is often reduced to pre-shipment inspection for most buyers. Of course, performing even one inspection may save lots of money and trouble but if the shipment is actually rejected, the importer cannot deliver on time to their client: it is a loss of time, money and customer satisfaction. To prevent those risks, buyers can opt for a more proactive quality control approach, and even implement an affordable but full-coverage quality assurance program.

The term quality control is often reduced to pre-shipment inspection for most buyers. Of course, performing even one inspection may save lots of money and trouble but if the shipment is actually rejected, the importer cannot deliver on time to their client: it is a loss of time, money and customer satisfaction. To prevent those risks, buyers can opt for a more proactive quality control approach, and even implement an affordable but full-coverage quality assurance program.

Una gran oferta de servicios de inspección son ofrecidos a los compradores con el fin de controlar la mercancía a lo largo del proceso de producción y previo a su embarque y cada uno de estos servicios permiten lograr objetivos específicos en cuanto al control y al aseguramiento de calidad. Entonces para qué sirve una inspección durante la producción y cuáles son sus objetivos?

Una gran oferta de servicios de inspección son ofrecidos a los compradores con el fin de controlar la mercancía a lo largo del proceso de producción y previo a su embarque y cada uno de estos servicios permiten lograr objetivos específicos en cuanto al control y al aseguramiento de calidad. Entonces para qué sirve una inspección durante la producción y cuáles son sus objetivos?