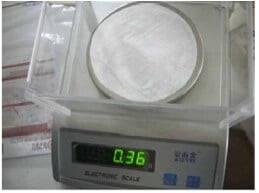

The GSM test is a measurement of Grams per Square Meter, and is one of the most important methods of determining the weights of knitting fabric, non-woven fabric or paper cardboard. Woven fabric, fabric with coating, or laminated fabrics are not as commonly tested using the GSM method, therefore the customer would need to give unique specification prior to GSM testing.

The GSM test is a measurement of Grams per Square Meter, and is one of the most important methods of determining the weights of knitting fabric, non-woven fabric or paper cardboard. Woven fabric, fabric with coating, or laminated fabrics are not as commonly tested using the GSM method, therefore the customer would need to give unique specification prior to GSM testing.

Manufacturing and Quality Control blog

- Home

- Manufacturing and Quality Control blog

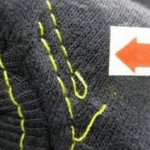

La inspección de prendas de vestir es un asunto complicado. Usted debe estar seguro de medir los tamaños, ver el peso del material y la composición, y por supuesto, comprobar si hay defectos cosméticos. Los defectos cosméticos en la ropa son numerosos: desde los botones que faltan, hasta la división y los agujeros de las costuras. Pero la comprobación de los rollos de tela debe ser fácil, entonces, ¿no? No son muchos los posibles defectos y las medidas son más fáciles, ¿verdad? En realidad, esto es todo lo contrario; el control de calidad de la tela es muy difícil y requiere métodos precisos. El inspector debe comprobar la conformidad, como por ejemplo, ¿son los rollos de la tela adecuada, los colores y la sensación, la longitud correcta y adecuadamente embaladas?

La inspección de prendas de vestir es un asunto complicado. Usted debe estar seguro de medir los tamaños, ver el peso del material y la composición, y por supuesto, comprobar si hay defectos cosméticos. Los defectos cosméticos en la ropa son numerosos: desde los botones que faltan, hasta la división y los agujeros de las costuras. Pero la comprobación de los rollos de tela debe ser fácil, entonces, ¿no? No son muchos los posibles defectos y las medidas son más fáciles, ¿verdad? En realidad, esto es todo lo contrario; el control de calidad de la tela es muy difícil y requiere métodos precisos. El inspector debe comprobar la conformidad, como por ejemplo, ¿son los rollos de la tela adecuada, los colores y la sensación, la longitud correcta y adecuadamente embaladas? Already, we have introduced

Already, we have introduced