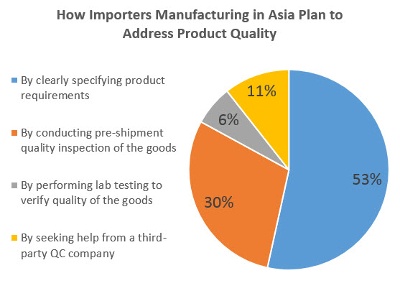

Since October 2016, we surveyed 217 visitors to our website that said they import from Asia and that “managing product quality” is their biggest manufacturing challenge. When asked “how do you plan to manage product quality” 116 of you, about 53 percent, responded with “by clearly specifying product requirements”.

Since October 2016, we surveyed 217 visitors to our website that said they import from Asia and that “managing product quality” is their biggest manufacturing challenge. When asked “how do you plan to manage product quality” 116 of you, about 53 percent, responded with “by clearly specifying product requirements”.

How to prevent quality defects in their products is definitely a top concern for many importers manufacturing in China, Vietnam, India and elsewhere in Asia. And making your product requirements clear to your supplier is certainly a helpful and cost-effective way to approach limiting product defects. Countless importers have lost money due to customer returns and unsellable products simply because their suppliers didn’t clearly understand expectations before manufacturing and shipping their goods.

But how exactly do you ensure your supplier fully understands your expectations for your product?

Experienced importers understand that suppliers typically aren’t aiming to “make a quick buck” by selling their customers substandard goods at the lowest possible cost to manufacture. Most suppliers want to provide their customers with a product that closely meets their specifications so that the supplier can retain their business for as long as possible. There are a number of ways you can clarify your requirements to help you get the product you want while limiting defects.

Addressing quality defects in a QC checklist

A quality control checklist, or QC checklist, is the most important document for ensuring your supplier and any staff inspecting your product understand your expectations. An effective checklist provides factory and QC staff with your requirements and inspection standards for your product’s appearance, performance and functions. An inadequate checklist exposes you to a greater risk of receiving defective products. It can also hinder QC staff’s ability to apply your standard when assessing your product.

Importers and QC professionals usually divide their checklist into four distinct sections, each covering different aspects of a product and its packaging:

1. Product requirements

The most important section for most importers to include in their QC checklist is one specifying product requirements. These requirements often include product dimensions, volume, weight, material, color, labeling and others. For example, you might specify tolerances of “± 1 cm” for certain measurements of a garment or a Pantone color code of “337 U” for part of a children’s toy you’re manufacturing.

The most important section for most importers to include in their QC checklist is one specifying product requirements. These requirements often include product dimensions, volume, weight, material, color, labeling and others. For example, you might specify tolerances of “± 1 cm” for certain measurements of a garment or a Pantone color code of “337 U” for part of a children’s toy you’re manufacturing.

When quality defects render a product unsellable due to a misunderstanding of requirements, it’s most often because the importer didn’t provide current and detailed specifications. This area of the checklist is your best safeguard against such issues. And it’s a basic necessity for all importers, no matter how familiar you think a factory is with your product.

2. Packaging requirements

Almost all items require packaging when shipping, so most QC checklists should also address packaging requirements. A well-defined packaging requirement section ensures that the necessary documentation and information will be displayed on shipping cartons throughout the export and import process. A clear packaging requirement section will also minimize damage to your goods during shipment and ensure the goods arrive in your hands in the same condition that they left the factory.

Your QC checklist can also outline retail specific packaging requirements, like those of Amazon’s Fulfillment by Amazon (FBA) program. Pre-shipment quality control inspection is essential to ensuring compliance with FBA and programs like it. A seemingly minor problem, like incorrect barcodes applied to cartons, could lead your distributors to reject an order. And it’s often more costly and difficult to resolve any problems with packaging or the product itself after the order has left the factory.

3. On-site product tests and checks

The third section of a QC checklist outlines necessary product tests and checks that the inspector should conduct on-site. Product tests help ensure the product conforms to any standards or claims of performance, safety or function. This section will vary greatly between different product types—from blade strength testing for ceramic knives, to hi-pot testing for electrical appliances.

This section of QC checklists also typically includes a variety of testing equipment and tools required. If you’re hiring a third-party inspector, be sure to clarify who will provide the tools and equipment for testing in the checklist. Inspectors often can’t conduct the testing you require when the party you expect to provide the necessary equipment doesn’t know it’s their responsibility.

This section of QC checklists also typically includes a variety of testing equipment and tools required. If you’re hiring a third-party inspector, be sure to clarify who will provide the tools and equipment for testing in the checklist. Inspectors often can’t conduct the testing you require when the party you expect to provide the necessary equipment doesn’t know it’s their responsibility.

You’ll also want to carefully establish the details of your required testing procedures. What temperature should inspectors subject your oven mitt to? For how many seconds? What materials should inspectors use as fodder for testing your electric blender? A QC professional with experience in your product category can often advise what types of testing and procedures are appropriate for you. You’re far more likely to receive accurate inspection results and have your product pass on-site testing if both your supplier and QC staff understand these.

4. Defect classification

Your QC checklist should define how your supplier and QC team should consider and report product defects found during inspection. In the QC industry, product defects are typically classified into three types, “critical”, “major” and “minor”:

- A critical defect renders the item unusable or poses risk of harm to the end consumer

- A major defect adversely affects performance of the product or is otherwise likely cause a customer to return the product

- A minor defect is usually an insignificant issue, often related to the product’s appearance, that doesn’t affect the item’s function or form

While QC professional generally follow these guidelines, you can and should define different defects under different categories as you see fit.  For example, some importers of promotional sunglasses might consider a scratch in the lens to be a minor defect. But you might specify in your checklist that QC staff treat a scratch found during inspection as a major defect, especially if your sunglasses are higher end.

For example, some importers of promotional sunglasses might consider a scratch in the lens to be a minor defect. But you might specify in your checklist that QC staff treat a scratch found during inspection as a major defect, especially if your sunglasses are higher end.

Once you’ve determined how to categorize each defect, it’s time to set a tolerance for how many of each category of defect you’ll allow in your order. If you’re utilizing the AQL framework to conduct inspections, setting acceptable quality levels can define the allowable defects for each category of defects for you.

Remember to keep your QC checklist updated and as detailed, yet concise, as possible. The document should be comprehensive enough to include all your requirements but succinct and organized so that the relevant people can reference it quickly. You might assume that certain requirements or inspection criteria for your product are obvious to your supplier and inspectors. But there’s no guarantee either party understands these if you don’t include them in the checklist you provide before mass production and QC inspection.

Other documents that help you prevent quality defects

A QC checklist is typically the most effective document available for outlining importers’ product requirements and standards. But a checklist is by no means the only way to make your expectations known to your supplier. Other documents can also help you prevent quality defects early and hold your supplier accountable for any unacceptable findings in your finished goods.

Including quality requirements in your purchase order

You don’t have to limit your purchase order (PO) to include only basic information, like payment terms, item descriptions and a breakdown of quantities per SKU. You can also use your PO to clarify product requirements and quality control inspection criteria to your supplier and inspector. Setting these expectations in the PO can be especially effective because:

- Your supplier is likely to closely review this document, and

- You’ll typically issue your PO to your supplier well before the factory begins mass production, so you can be more confident your supplier has your requirements before they have a chance to make any mistakes in production

Some importers also use the PO to hold factories accountable to QC requirements by setting financial penalties for failing certain tests or not passing inspection (related: 3 Ways to Handle Defective Products). The only way to hold suppliers accountable to such expectations is to set them early on in written documentation so that they can be reviewed and agreed upon. You’ll have much less leverage you wait until after product inspection reveals defects to announce your intention of holding that supplier accountable (related: 3 Keys to Addressing Quality Issues with Your Supplier).

Addressing product defects and consequences in a vendor agreement

A vendor agreement is a third document that importers can use to set clear expectations to a supplier, even before issuing a PO. A vendor agreement, sometimes called a vendor guide, outline policies and procedures that a manufacturer must follow to supply your products.

Vendor agreements tend to be much longer than POs or QC checklists, often including multiple sections addressing QC inspection requirements, packaging standards and shipping and logistics information. Agreements required by large retailers, like Walmart and Costco, also commonly include social compliance standards suppliers are expected to meet.

The key section of a vendor agreement is the terms and conditions section. This part defines accountability and any financial or other consequences a supplier might face for not meeting the terms of the agreement. Larger brands or retailers often intend for their vendor agreement to be legally binding. But the main value these agreements provide most importers lies in setting expectations to avoid unacceptable defects and other issues.

Your ability to hold a supplier legally accountable may be difficult or costly, especially if you can’t afford to take your supplier to court over a dispute. If you expect your agreement to be a formal contract, it’s best to have the document drafted by a lawyer in the local jurisdiction in which your supplier is based. It’s not uncommon for importers to find that a court in a foreign country, like China, refuses to enforce a contract drafted in their home country.

Conclusion

Expert importers can attest that having clear and well-defined requirements for their products prior to production is key to preventing product defects. Factory capabilities certainly play a role in the quality defects that are likely to end up in your products. But you’ll find that it’s much easier to hold factories accountable if you’re able to clearly make your requirements known to them ahead of production (related: Preventing Product Defects Starts with Negotiating with Suppliers).

There are several helpful documents available for importers to create frameworks to prevent and address product defects should they occur. QC checklists, purchase orders and vendor agreements can all help ensure that your supply chain functions smoothly and your brand isn’t tarnished by poor quality products.

Where have you found the most success in preventing defects? Share your experience in the comments section below!