Do you have China quality control all wrong?

What ideas normally come to mind when you see the words “Made in China” on a product label? What role do you think quality control (QC) staff play in ensuring the products you source from China meet your standards? These are just a couple of questions that often provoke false beliefs in the minds of consumers and importers alike.

What ideas normally come to mind when you see the words “Made in China” on a product label? What role do you think quality control (QC) staff play in ensuring the products you source from China meet your standards? These are just a couple of questions that often provoke false beliefs in the minds of consumers and importers alike.

You may be considering sourcing products from China for the first time. Or maybe you’ve already been manufacturing products in China for many years. But regardless of experience level, you’ve likely held onto one or more common misconceptions of China quality control at one time or another.

Our understanding of QC in China can have far-reaching effects. As an importer, you might fall victim to manufacturing problems if you don’t fully understand how QC inspectors work with your suppliers. Sourcing agents, purchasers and supply chain managers around the world may find working with Chinese suppliers more difficult.

In this eBook, we’ll explore the ramifications of different misconceptions as they relate to importers, specifically. You’ll learn about five of the most commonly-held false beliefs surrounding QC inspection and product quality in China and why they persist today.

In dispelling these misconceptions, you’ll have a smoother experience sourcing from China, free of many of the frustrations that other importers often face. You can also expect that a better understanding of China inspection practices will improve your relationship with your Chinese suppliers.

Read along, email a PDF to yourself for later by filling out the form on this page or click the links below to jump to the section that interests you most:

Misconception #1: Chinese factories only make poor quality products

Where does this perception come from?

The perception that China only manufactures sub-standard goods is popular among many importers and consumers. Importers considering sourcing from China for the first time often worry about the quality they’ll receive in the finished product. And consumers sometimes place lower value on a product that’s known to be manufactured in China.

The most likely cause for this belief is reports of product issues that have appeared in popular media over the last 10-20 years. A few notable examples are:

The 2008 Chinese milk scandal, perpetrated by Sanlu Group, led to six infant deaths and tens of thousands more hospitalized. The company was found responsible for adulterating infant formula and similar food products with the toxic chemical melamine. Melamine gives the appearance of higher protein content when combined with milk.

The 2008 Chinese milk scandal, perpetrated by Sanlu Group, led to six infant deaths and tens of thousands more hospitalized. The company was found responsible for adulterating infant formula and similar food products with the toxic chemical melamine. Melamine gives the appearance of higher protein content when combined with milk.- The 2007 Mattel toy recall involved withdrawing one million toys from American stores after it was discovered some of the Chinese-made products weren’t safe for children. The toys were found to have paint with excessively high levels of lead.

- Poorly Made in China is a book authored by Paul Midler and published in 2009 which includes first-hand accounts of product quality problems in China. One specific point discussed is “quality fade” – a process whereby the manufacturer gradually lowers the quality of inputs to widen profit margins.

No doubt these examples gave many importers cause to question how their products are made. And it’s important to provide adequate oversight at your supplier’s facility to ensure products meet your requirements, not only for consumer safety, but for quality as well.

China’s move up the industrial value chain

Why are popular claims about the poor quality of Chinese products exaggerated? Let’s look at how far China has come in industrializing and where it’s expected to go in the future.

Most, if not all, industrialized nations have been guilty of manufacturing or product safety scandals at one time or other. Upton Sinclair’s classic 1906 novel called The Jungle exposed product safety hazards in America’s meat packing industry at the time.

Japan, a country today known for its high product quality, was once ranked among the lowest in the world. Renowned quality management evangelist Joseph M. Juran wrote in his 1981 paper, “Product Quality – A Prescription for the West”:

Prior to World War II Japanese product quality was poor – it was widely regarded as among the worst… Soon after World War II Japanese quality began to improve and the pace of improvement has been remarkable. My estimate is that by the mid-1970's this pace had brought the Japanese to a state of equality with the West.

Many countries that experienced quality and other manufacturing problems in the wake of industrialization are today among the most consistent and reliable exporters in the world. And China—the largest exporting country by total dollars, as of 2015—appears to be following the same path as its predecessors. We see this in China’s rapid move up the industrial value chain, characterized by the following:

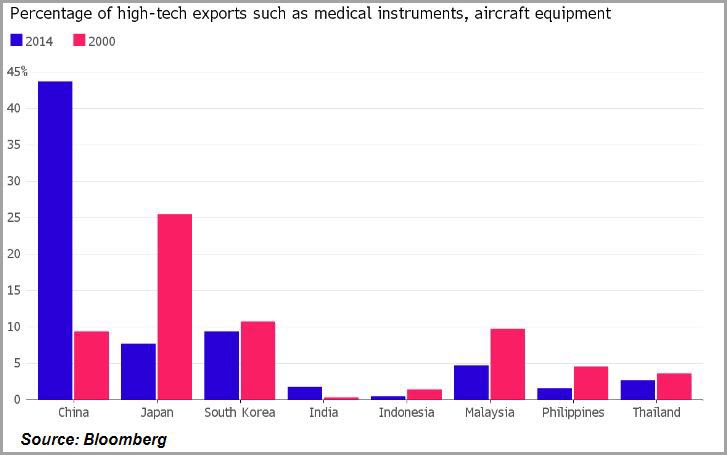

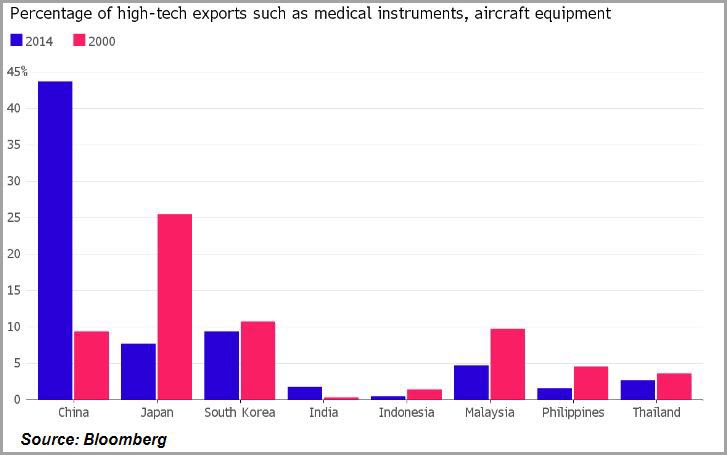

- An increase in high-tech exports – China overtook Japan as Asia’s top high-tech exporter in 2015

- A growing number of tech companies – China is home to DJI, Huawei, Baidu, Lenovo, BYD, Tencent and Alibaba Group

- Increased sophistication in manufacturing – Chinese factories are becoming automated, as the country is now the world’s largest market for industrial automation and robots

- “Made in China 2025” – a government initiative aiming to upgrade factories and infrastructure to make Chinese industries more competitive by 2025

Chinese factories are certainly capable of manufacturing high quality products. So why do some importers continue to receive shipments of poor quality goods?

“You get what you pay for” when sourcing products from China

Experienced importers know that the phrase “you get what you pay for” applies as much to China as it does anywhere else.

You might insist on haggling with your supplier for the lowest price on leather furniture, for example. But the likely result is that this lower price will come at the expense of lower quality in the finished goods—perhaps lower quality leather, in this example. That’s because demanding lower prices typically forces the supplier to use lower quality parts and materials in your product in order to maintain profit margin.

Suppliers tend to provide what the market demands. And when many importers flock to China to pursue lower cost manufacturing, the result is often lower quality outputs.

How to get the China product quality you want

Not every importer demands high quality. Importers of promotional goods, for example, tend to operate with smaller margins. Their customers expect to pay a lower price but also tend to accept lower quality than they might for other types of products. These importers are generally content with relatively low product quality, as long as it’s met with a corresponding discount in price.

But importers that strive for the highest quality level possible and are disappointed with the finished goods they receive have usually made one of the following mistakes:

But importers that strive for the highest quality level possible and are disappointed with the finished goods they receive have usually made one of the following mistakes:

- Negotiating too hard on price, forcing the supplier to recoup their costs by using cheaper, lower quality parts and materials, or

- Failure to adequately clarify specifications and requirements for their product

Many importers find it difficult to negotiate. They’re often afraid to offer a “target price” to potential suppliers because they worry that doing so might limit their ability to ask for a lower price later. In fact, being upfront with a supplier about what you expect to pay helps you avoid quality problems. Even well-established factories that produce high quality goods can usually accommodate a lower price by using cheaper materials.

But by refusing to reveal what you expect to pay, you force the supplier to guess your desired price and quality level. And understandably, that supplier might quote you a lower price so they can appear more competitive (related: 3 Tips for Getting the Best Price from Suppliers).

At the same time you’re being direct in negotiating with a supplier, you should also be direct in stating your expectations for your product. Be clear about your quantities and order volume, specifications, any requirements for pre-shipment inspection to verify quality, shipping deadlines and other considerations. You’ll also typically benefit from developing a QC checklist for your product – an important document which helps to ensure the finished product meets your requirements.

Open and direct communication with your supplier is the key to getting the product you want at the price point and quality level you desire.

⇑ Back to Top

Misconception #2: Chinese suppliers always understand requirements

Many importers wrongfully assume that their Chinese supplier fully understands their expectations. But most seasoned importers have faced at least one major problem due to a misunderstanding in their dealings with a supplier, whether sourcing products from China or elsewhere.

Problems can range from production or shipping delays to unacceptable quality, unsellable goods or worse. And misunderstandings involving Chinese suppliers normally stem from a few common issues with communication.

Requirements lost when communicating through sales representatives

You may find that you’re forced to deal with a sales representative as your supplier’s main contact, especially if your supplier is a vendor or trading company. This isn’t at all unusual. Suppliers often rely on sales staff as the only personnel able to communicate with customers in English.

But the main problem with this arrangement is that sales staff typically work in an office, often outside the factory. The factory may be located in a different city—or country—altogether. This means that salesperson is an extra “layer” of communication between you and the production manager at the factory.

This can help eliminate misunderstandings due to language barriers. But it can also cause misunderstandings due to a lack of familiarity with production. Since the salesperson is often somewhat removed from the factory, they might miscommunicate production capabilities and product requirements between you and the factory.

Misunderstandings caused by language or cultural barriers

Importers sometimes attribute language barriers as the cause for an error on the part of their supplier. And it can help to bring a translator when meeting with your supplier to review requirements before the factory begins mass production.

But cultural differences are actually to blame for most problems importers think are caused by a language deficiency. One common example is when a Chinese supplier tells the importer what they think their customer wants to hear, even when that’s not the full truth. For example, your supplier may tell you they can ship your finished goods within four weeks, while knowing they actually won’t be able to ship them for at least six weeks.

Another common problem can occur when a Chinese supplier is afraid to ask questions or admit they don’t understand your requirements. This normally stems from a fear of appearing incompetent, which is common in much of Each Asia. Let’s say you’ve forgotten to send an important product specification to your supplier, such as a sizing chart for the garments you’re manufacturing. Your supplier might make assumptions, rather than asking you directly to clarify or provide the spec.

It’s easy to see how these seemingly minor cultural differences, or simply a desire to please, can have major consequences on your experience sourcing from China.

Mistakes caused by unfamiliarity with a foreign product

You might expect factory managers to be experts in the products they’re manufacturing. But they occasionally make mistakes because they don’t understand the intended use for a product.

For example, one importer found that the ceramic butter dishes they ordered from China couldn’t actually hold a standard 4-ounce stick of butter. The dish was too small. The importer probably could’ve avoided the misunderstanding by clarifying their product dimensions, but they assumed this was common knowledge to the factory. But butter isn’t a common household item in China and factory workers simply weren’t fully aware of what the product was intended to hold.

For example, one importer found that the ceramic butter dishes they ordered from China couldn’t actually hold a standard 4-ounce stick of butter. The dish was too small. The importer probably could’ve avoided the misunderstanding by clarifying their product dimensions, but they assumed this was common knowledge to the factory. But butter isn’t a common household item in China and factory workers simply weren’t fully aware of what the product was intended to hold.

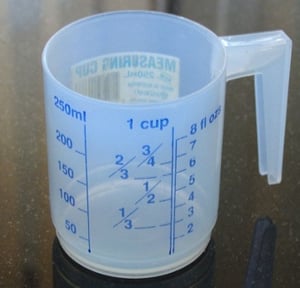

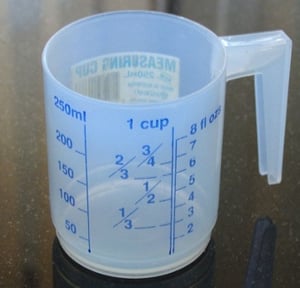

Similar confusion has occurred when importers specify using a “cup” as a standard unit of measurement. While customary in the United States, many countries, including China, rely on the metric system of measurement (milliliters and grams). Chinese suppliers could easily mistake a “cup” to mean any small open container used for holding drinks.

How to ensure your Chinese supplier clearly understands your requirements

You might now be worried about all the possible ways in which your Chinese supplier is going to misunderstand you. And if you’re like most importers, you’re probably wondering what you can do to avoid the problems that often follow misunderstandings (related: 3 Ways to Improve Communication with Suppliers).

Firstly, it helps to voice your expectations and concerns directly to someone at the factory that will be manufacturing your product. If possible, try to contact the production manager, QC manager or a similar person at the factory that will be directly overseeing production or quality control of your product.

You may need to hire a translator and arrange a meeting at the factory. But it’s often worthwhile to talk to the people that will actually be handling your product, rather than only talking with a salesperson who may be working in a remote office.

Sometimes vendors will hesitate to divulge the identity of factories, fearing that their customers may try to “cut them out” and work directly with the factory. If this is an issue for you, consider offering to sign a non-compete agreement with your vendor to help relieve their concerns.

Secondly, follow these best practices when corresponding with your supplier contact:

- Keep emails simple and maintain one continuous email chain so it’s easier for both you and your supplier to follow

- Follow up important emails with a phone call to clear up any points of confusion and confirm that your supplier understood your message

- Limit the number of supplier contact people you communicate with to avoid any conflicting messages

Thirdly, clearly state your requirements. The best places to include your requirements are in your purchase order and, most importantly, your QC checklist. Both should be developed and agreed upon by you and your supplier before mass production begins.

Not only do these documents help ensure a mutual understanding of what’s expected, they also help you hold your supplier accountable for meeting your expectations.

⇑ Back to Top

Misconception #3: QC inspection companies can force inspection on Chinese factories

Many importers insist on pre-shipment inspection to verify the condition and quality of Chinese products. Some importers rely on the factory’s own QC staff to inspect, while others may choose to personally visit the factory and check the products. Then there are importers that will either hire full-time inspection staff or contract a third-party QC company to inspect on their behalf.

No inspection method is a one-size-fits-all solution for every importer. But those that hire a professional QC company often misconceive what their inspectors can do at a Chinese factory.

The limited authority of third-party inspectors

Importers that are new to hiring a third-party inspector to visit their supplier’s factory often assume that their job is done as soon as they introduce their inspector to their supplier. But successful inspection in China often requires some direct pressure from the importer to their supplier (related: Why Product Inspection Companies Can't Compel Your Chinese Suppliers)

Many Chinese suppliers try to resist third-party inspection for a couple of reasons, including:

- They may fear the added scrutiny of outside inspection may raise their costs if delays are caused or goods need to be reworked or replaced

- They may not want you to know if they’re subcontracting to other factories to fulfill your order or which factories they’re working with

Outside inspection requires the full cooperation of factory management and staff. Inspectors can’t just walk into a factory unannounced and start poking around. Instead, factory staff must agree to invite inspectors into the facility and allow them to inspect.

How to prevent resistance to third-party inspection

Third-party inspectors serve to moderate the relationship between importers and suppliers. They can’t force your suppliers to do anything against their will. And you’ll typically need to intervene if your supplier shows signs of resistance to outside inspection, such as stalling or not responding to inquiries from your China inspection provider. But it’s often better to take action to prevent any resistance early, rather than push a reluctant factory to comply with outside inspection.

The most effective way to ensure your supplier will cooperate with inspection is to inform them that you require it before you place an order. You can mention your expectation for third-party inspection directly in your purchase order. This helps you hold your supplier accountable for inspection and avoid surprising them by suddenly demanding it later.

It also helps to walk your supplier through the inspection process ahead of time. Explain how many units the QC team will inspect, the inspection criteria, what tests they’ll perform in the factory and what quality issues they’ll look for. Provide your supplier with a detailed and current QC checklist so they’re clear on the standard inspectors will use for evaluating your product. This can help put your supplier at ease.

Ultimately, your supplier must agree to any outside factory audit or product inspection. So it’s wise to make your requirement clear as early as possible.

⇑ Back to Top

Misconception #4: QC companies work directly with Chinese factory staff to fix quality issues

Just as importers sometimes overestimate the authority of their third-party QC provider, they’re also prone to overestimating their inspector’s ability to change the way their supplier operates. Some importers expect their QC company to:

- Arrange inspection with the supplier

- Develop inspection criteria

- Visit the factory and find any issues and their root causes

- Work directly with factory staff to fix quality issues and improve product quality

As we’ve already seen, arranging inspection requires the factory’s full cooperation—and often insistence from the importer. And you’ll find your inspection criteria are much more effective when you work with your QC inspector and supplier together to develop them.

But what about the last two steps in the process above?

What inspectors actually do at the factory

The chief responsibility of a product inspector is to check the goods at the factory and report on their condition, quality and adherence to requirements.

Importers that hire inspectors benefit by being able to “see” their product, through a detailed report, without having to actually travel to their supplier’s factory. This gives importers assurance of what they’ll receive before the shipment leaves the factory.

Inspectors often have a background in a particular product category, such as textiles or furniture. A QC company may even have separate divisions with staff dedicated to inspecting particular product types. But inspectors generally only find problems and report them. They typically don’t pinpoint the exact cause of a product defect (related: Why QC Inspectors Rarely Work with Chinese Staff to Fix QC Issues).

Let’s say you're sourcing from China towels with an embroidered logo. Your inspector finds a press mark on all the finished towels. The inspector might ask a factory representative if they know what caused the impression and then note their response in the report. But chances are, even if that inspector is experienced, they won’t be able to say for sure what’s causing the defect on the towels.

Of course, the causes of some defects are more obvious than others. Excess material, or flash, in an injection-molded product normally indicates an issue with the mold. Defects found in products manufactured primarily with manual labor, in particular, are normally fairly easy to diagnose, such as untrimmed threads on a garment. But you’ll generally need help from an engineer to troubleshoot more complex production processes.

Finding root causes for complex problems with a process audit

Contrary to what many importers believe, root cause analysis is outside the scope of a typical third-party inspection.

Instead, you may need an engineer to visit the factory and perform what’s called a process audit. During a process audit, an engineer can investigate any part of the factory’s production line, from looking at raw materials during incoming quality control, to manufacturing and packaging the finished goods.

In one case, an importer of wood molding found a high incidence of warping in the product, a defect resulting in customer returns. Product inspectors were able to measure the moisture content of the wood and report on units affected by warping. But inspection alone couldn’t identify the root cause of the warping, due to the number of processes involved, such as:

- Initial cutting

- Joint splitting

- Joint connecting & binding

- Curing

- Milling

- Gesso coating & drying

- Decorative pressing

- Packaging

A process audit was needed to investigate each production area in isolation and determine the cause of the warping issue.

How to fix problems found during an inspection or audit

When an inspection reveals problems with your product, you’ll typically need to address these directly with your supplier. Inspectors and auditors have no authority to force factory managers and staff to change their ways. But the majority of importers will find that their leverage as a customer is enough to compel their supplier to improve. In fact, your supplier may even be glad to know of any quality issues they can fix to improve their business.

A willingness to cooperate with inspection and take responsibility for any problems found can make the difference between a good supplier and a bad one. And if you repeatedly inform your supplier of unacceptable quality issues and still don’t see improvement, you may want to look for a new supplier altogether.

⇑ Back to Top

Misconception #5: Your inspection results directly indicate whether your Chinese supplier should ship an order

A timely inspection report of your shipment can be a very valuable tool for giving insight into the state of your product.

But some importers make the mistake of merely glancing at the overall inspection results shown in the report and then advising their supplier about whether to ship the order on that basis. Other importers even assume that the overall result automatically determines whether the factory should ship and that no feedback is needed from them at all before doing so.

How to interpret your inspection results

Knowing how to interpret your report will save you time, while at the same time keep you informed. Most product inspection reports have an overall result somewhere near the top or bottom, with one of three possible outcomes as shown below.

Pass

Sometimes reported as “accepted”, this overall result shows that:

- The inspector didn’t find any significant issues with the product

- The product mostly conformed to the criteria you specified, and

- Any defects found were within tolerance, usually chosen prior to inspection and set by the acceptable quality limit (AQL) standard

Fail

Sometimes reported as “not accepted”, this overall result shows that either:

- The inspector found an issue affecting a large portion of the order, typically 15 percent or more and sometimes called a “general defect”

- The product didn’t meet one or more of your criteria

- The product failed one or more important on-site tests, or

- The number of quality defects found exceeded the tolerance set by AQL

Pending

This overall result would otherwise be pass, except:

- There were one or more issues found that lack a clear reporting standard or

- The inspector wasn’t able to perform one or more important checks or on-site tests

For example, you’ll commonly see a pending result when product weight or dimensions differ from the expected result or if you haven’t provided a tolerance.

You might also receive a pending result if certain equipment wasn’t available for on-site testing, or factory staff didn’t allow the inspector to conduct a check or test specified. An example of testing that Chinese factories sometimes won’t allow is the carton drop test. Though an industry standard for most consumer goods, this test can often damage packaging or the product inside.

The terms pass, fail and pending don’t just apply to the overall inspection results. Inspectors also typically apply a pass, fail or pending rating to each individual item, or stock keeping unit (SKU), inspected. That’s why it’s important to look over the whole report, rather than only checking the overall result.

You may want to look closely at any pending inspection results or remarks, or contact the inspector to find out how serious these are, which will determine how your inspector should report them in the future. Likewise, you might find the inspector was too strict or too lenient in their reporting. And advising them to adapt to your preferred reporting method will make it easier to interpret future reports.

How to use the information in your China inspection report

Inspection reports themselves don’t generally dictate to the factory whether to ship the goods. Ultimately, only you as the importer can judge whether or not to approve the order. The report merely gives you as much relevant information as possible to help you make an informed decision.

And just because the overall inspection result is pass or fail doesn’t necessarily mean you should approve or hold the order. No one knows your customers and their expectations better than you do.

Conclusion

Now you’re aware of five of the most common misconceptions surrounding product quality and inspection in China. And you’re in a better position to source products from China, while avoiding many of the pitfalls that commonly lead to poor quality products.

If nothing else, it’s our hope that you now understand that Chinese factories CAN and DO produce high-quality products for importers that know how to work with them. Work with your supplier and China quality control team to develop a detailed checklist for your product. And remember that you dramatically increase your chances of success with sourcing products from China by communicating your expectations openly and directly with your supplier.

⇑ Back to Top

More resources

Still struggling to communicate your requirements to Chinese suppliers? Check out our eBook below to find out how QC checklists can help your clarify your quality expectations when sourcing from China!

What ideas normally come to mind when you see the words “Made in China” on a product label? What role do you think quality control (QC) staff play in ensuring the products you source from China meet your standards? These are just a couple of questions that often provoke false beliefs in the minds of consumers and importers alike.

What ideas normally come to mind when you see the words “Made in China” on a product label? What role do you think quality control (QC) staff play in ensuring the products you source from China meet your standards? These are just a couple of questions that often provoke false beliefs in the minds of consumers and importers alike. The

The

But importers that strive for the highest quality level possible and are disappointed with the finished goods they receive have usually made one of the following mistakes:

But importers that strive for the highest quality level possible and are disappointed with the finished goods they receive have usually made one of the following mistakes:

For example, one importer found that the ceramic butter dishes they ordered from China couldn’t actually hold a standard 4-ounce stick of butter. The dish was too small. The importer probably could’ve avoided the misunderstanding by clarifying their product dimensions, but they assumed this was common knowledge to the factory. But butter isn’t a common household item in China and factory workers simply weren’t fully aware of what the product was intended to hold.

For example, one importer found that the ceramic butter dishes they ordered from China couldn’t actually hold a standard 4-ounce stick of butter. The dish was too small. The importer probably could’ve avoided the misunderstanding by clarifying their product dimensions, but they assumed this was common knowledge to the factory. But butter isn’t a common household item in China and factory workers simply weren’t fully aware of what the product was intended to hold.